In short, the sintering of stainless steel is a high-temperature thermal process that fuses metal powder particles together to form a solid, dense object. Crucially, this is achieved without actually melting the steel. Instead, a compressed shape made of steel powder and a binder is heated in a controlled atmosphere, causing the individual particles to bond through atomic diffusion, which increases the part's strength and density.

Sintering is not about melting metal; it's about using controlled heat below the melting point to transform a fragile, compressed powder shape into a strong, solid component by encouraging its particles to bond and fuse together.

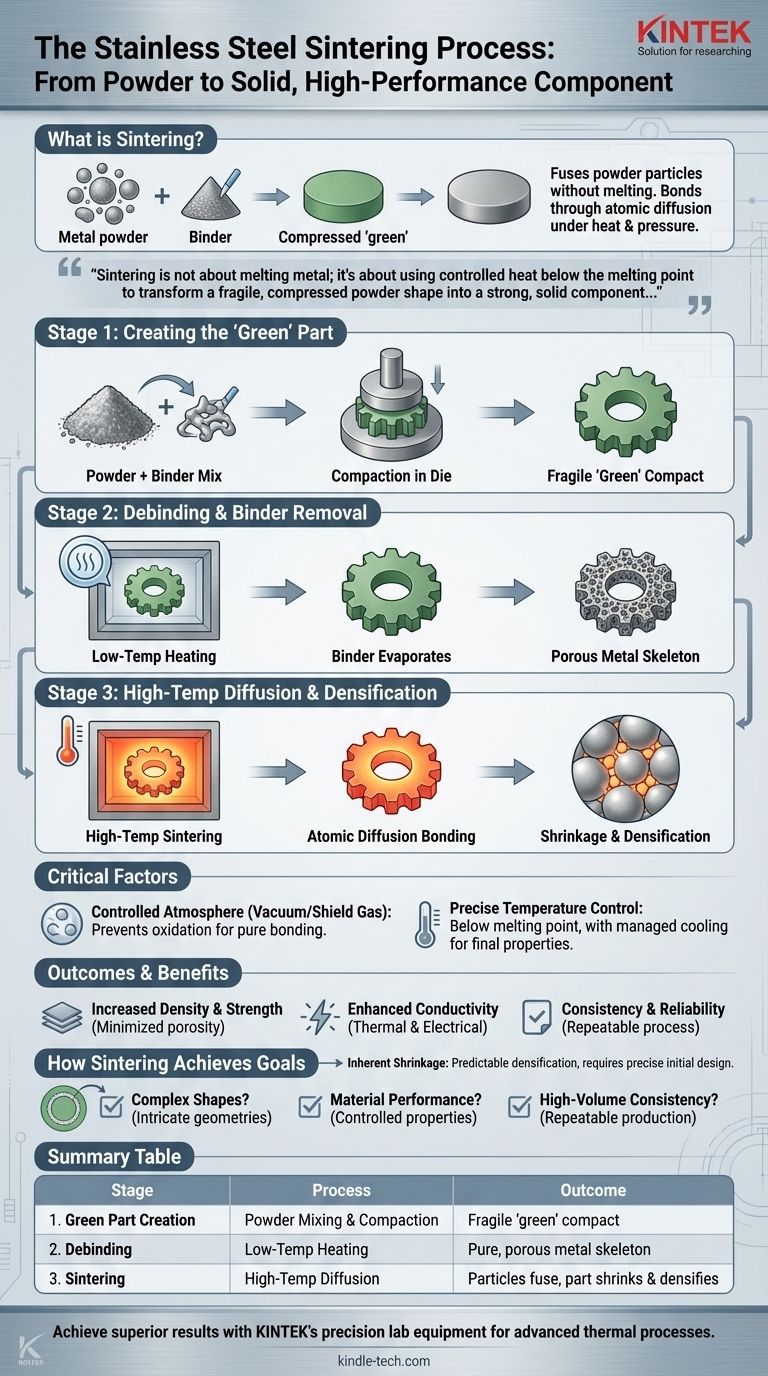

The Three Core Stages of Stainless Steel Sintering

The journey from loose powder to a finished metal part is a precise, multi-stage process. Each step is critical for ensuring the final component has the desired density, strength, and dimensional accuracy.

Stage 1: Creating the "Green" Part

First, fine stainless steel powder is thoroughly mixed with a temporary polymeric binder, such as wax or paraffin. This binder acts as an adhesive, giving the mixture enough cohesion to be handled.

This powder-binder blend is then pressed into a die under high pressure, forming it into the desired shape. This initial, fragile piece is known as a "green" part or a green compact.

Stage 2: Debinding and Binder Removal

The green part is then carefully placed into a furnace, often a vacuum or graphite furnace. It is heated to a relatively low temperature in a controlled atmosphere.

During this debinding phase, the organic binder evaporates or burns away completely. Maintaining a controlled gas flow is essential to carry away the binder residue and protect the furnace from contamination.

Stage 3: High-Temperature Diffusion and Densification

With the binder gone, the temperature is raised significantly, approaching—but never reaching—the melting point of the stainless steel.

At this high temperature, the metal particles begin to diffusion bond. Atoms migrate across the boundaries of contacting particles, causing them to fuse together. The contact points grow, pulling the particle centers closer, which eliminates the porous spaces between them and causes the entire part to shrink and densify.

Why the Sintering Environment is Critical

The success of sintering hinges on maintaining an immaculate and precisely controlled environment throughout the heating and cooling cycle. Failure to do so results in a weak, substandard part.

The Role of a Controlled Atmosphere

Sintering must be performed in an environment devoid of oxygen. This is typically achieved using a vacuum or a protective shielding gas (like an endothermic gas).

Oxygen would cause the steel particles to oxidize, forming a surface layer that prevents them from bonding. A controlled atmosphere ensures the particle surfaces remain pure and ready to fuse.

The Importance of Temperature Control

The sintering temperature is a delicate balance. It must be hot enough to activate atomic diffusion but remain safely below the steel's melting point.

Furthermore, the cooling rate after sintering is actively managed. Just like in other heat treatments, controlling how quickly the part cools can be used to fine-tune the final mechanical properties, such as hardness and ductility.

Understanding the Outcomes and Benefits

Sintering is not just a manufacturing method; it's a way to engineer materials for specific performance characteristics. The process inherently changes the material's structure.

Key Benefits: Strength, Density, and Consistency

The primary goal of sintering is to minimize the porosity of the green part. By fusing the particles and closing the gaps, the process significantly increases the component's density and strength.

Sintering also enhances other properties like thermal and electrical conductivity. Because the process is highly controlled, it produces parts with exceptional consistency and reliability across large production runs.

Inherent Shrinkage and Dimensional Control

A key characteristic of sintering is that the part shrinks as it densifies. This is a predictable and necessary part of the process.

Engineers must precisely calculate this shrinkage in the initial design of the mold and the green part to ensure the final, sintered component meets exact dimensional specifications.

How Sintering Achieves Specific Manufacturing Goals

Choosing a manufacturing process depends entirely on your objective. Sintering provides unique advantages for certain applications.

- If your primary focus is creating complex shapes: Sintering excels because it starts with a moldable powder, enabling intricate geometries that are difficult or costly to achieve with traditional machining.

- If your primary focus is material performance: Sintering provides precise control over density, porosity, and strength by manipulating temperature, time, and atmosphere.

- If your primary focus is high-volume consistency: The process is highly repeatable, making it ideal for manufacturing large quantities of identical parts with reliable mechanical properties.

Ultimately, sintering transforms loose stainless steel powder into a dense, robust, and precisely engineered component.

Summary Table:

| Stage | Process | Key Action | Outcome |

|---|---|---|---|

| 1. Green Part Creation | Powder Mixing & Compaction | Pressing powder with binder in a die | Forms a fragile, shaped "green" compact |

| 2. Debinding | Low-Temperature Heating | Removing the organic binder in a furnace | Leaves a pure, porous metal skeleton |

| 3. Sintering | High-Temperature Diffusion | Heating near melting point in controlled atmosphere | Particles fuse via atomic diffusion, part shrinks and densifies |

Ready to achieve superior strength and complex geometries with your metal components?

At KINTEK, we specialize in precision lab equipment and consumables for advanced thermal processes like sintering. Our expertise ensures your stainless steel parts achieve the optimal density, strength, and dimensional accuracy you require.

Contact our experts today to discuss how our sintering solutions can enhance your laboratory's manufacturing capabilities and deliver consistent, high-performance results.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What role does a high-temperature high-vacuum furnace play during the heat treatment of Alloy 690? Contamination Control

- Why is deposition chamber high vacuum? Essential for Purity and Control in Thin Film Deposition

- What is vacuum heating? Achieve Purity and Precision in High-Temperature Processing

- What is the principle of an arc melting furnace? Harnessing High-Current Electric Arcs for Metal Melting

- What is the necessity of vacuum annealing for sponge zirconium? Ensure Stability in EBM Refinement

- Why is a vacuum furnace or an atmosphere furnace using nitrogen essential for CFRP pyrolysis? Preserve Fiber Integrity

- What are the safety precautions for heat treatment process? A Guide to Managing Thermal, Atmospheric, and Equipment Risks

- What is the most important factor influencing the strength of the brazed joint? Master Joint Clearance for Maximum Strength