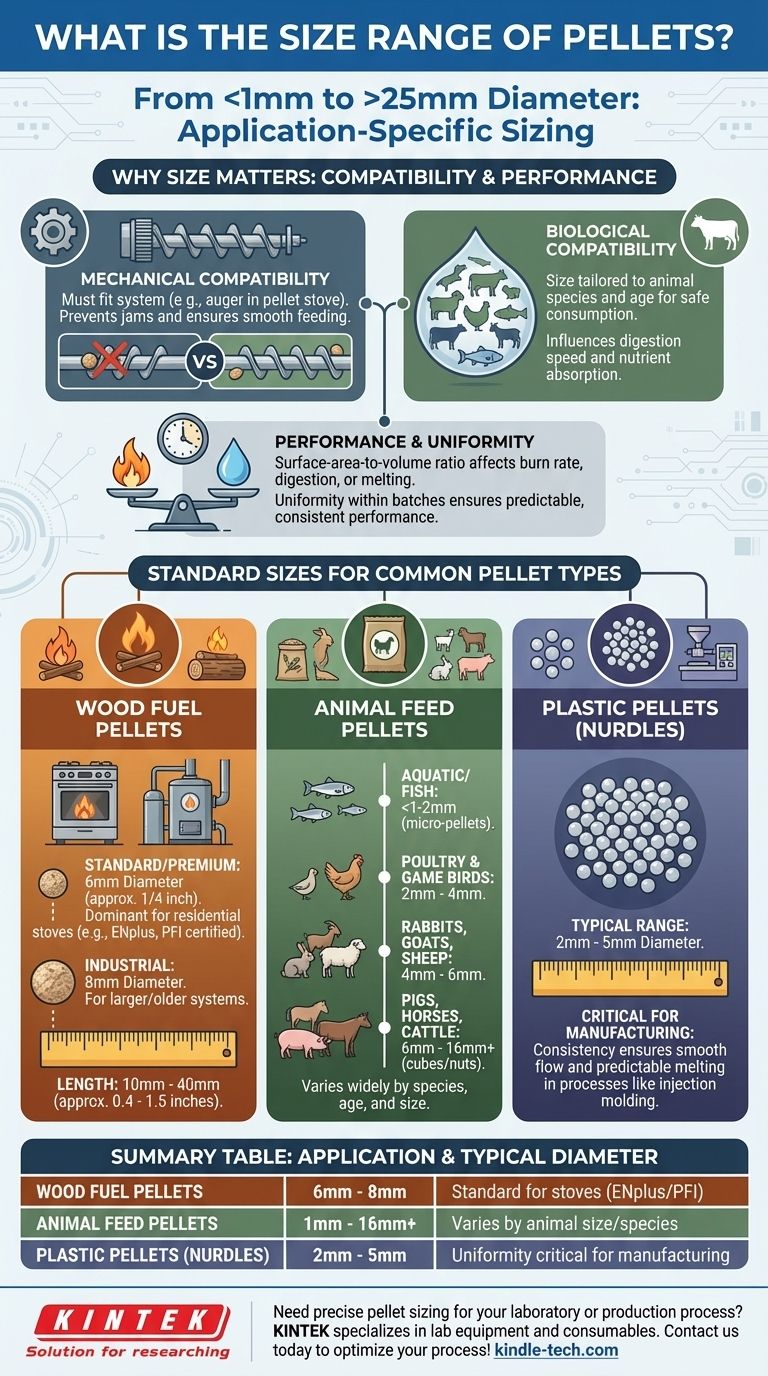

In short, pellets range in size from under 1 millimeter to over 25 millimeters (1 inch) in diameter. This wide variation exists because the term "pellet" describes materials for vastly different applications, from wood fuel and animal feed to industrial plastics. The required size is not a universal standard but is dictated entirely by the pellet's composition and, most importantly, its intended use.

The "correct" pellet size is fundamentally determined by its specific function. Choosing the right dimensions is a critical decision for ensuring efficiency, safety, and operational success, whether you're fueling a stove, feeding livestock, or running an industrial process.

Why Pellet Size is Application-Specific

Understanding why pellet dimensions vary so widely is key to making an informed choice. The size is engineered to be compatible with a specific system, whether that system is mechanical or biological.

The Principle of Compatibility

The most immediate factor is mechanical or biological compatibility. A pellet must physically fit the system it is designed for.

For example, a wood pellet stove has an auger—a screw-like mechanism—that feeds pellets into the burn pot. If the pellets are too large, they will jam the auger, shutting down the appliance.

Similarly, an animal feed pellet must be appropriately sized for the animal to consume it easily and safely. A pellet suitable for a horse would be a choking hazard for a chicken.

The Impact on Performance

Size directly influences performance characteristics like burn rate, digestion speed, or melting consistency.

Smaller pellets have a greater surface-area-to-volume ratio. This means they will burn faster, dissolve more quickly, or melt more evenly than larger pellets of the same material. In a pellet stove, this impacts heat output; in animal feed, it affects nutrient absorption.

The Role of Uniformity

For most applications, size uniformity within a batch is as important as the actual size. A consistent size ensures predictable performance.

Inconsistent pellet sizes can lead to operational problems like feeding jams, uneven heating, or inconsistent dosing of nutrients, making uniformity a key indicator of quality.

Standard Sizes for Common Pellet Types

While there is no single standard, well-defined size ranges exist for the most common pellet categories.

Wood Fuel Pellets

Wood pellets for heating are highly standardized to ensure compatibility with residential stoves and industrial boilers.

- Standard/Premium Grade: The most common size is 6 mm in diameter (roughly 1/4 inch). This is the standard for the vast majority of residential pellet stoves in North America and Europe.

- Industrial/Large-Scale Grade: Some larger or older systems use 8 mm diameter pellets.

- Length: The length of wood pellets typically varies from 10 mm to 40 mm (about 0.4 to 1.5 inches).

Internationally recognized certifications like ENplus and the Pellet Fuels Institute (PFI) have strict requirements for these dimensions to guarantee quality.

Animal Feed Pellets

The size of feed pellets is determined by the species, age, and size of the animal.

- Aquatic/Fish Feed: These are often the smallest, sometimes less than 1-2 mm for fry (young fish), and are called micro-pellets.

- Poultry and Game Birds: Typically range from 2 mm to 4 mm in diameter.

- Rabbits, Goats, and Sheep: Pellets are commonly in the 4 mm to 6 mm range.

- Pigs, Horses, and Cattle: These larger animals consume pellets from 6 mm up to 16 mm or even larger, sometimes referred to as "cubes" or "nuts."

Plastic Pellets (Nurdles)

Plastic pellets, also known as nurdles or resins, are the raw material for nearly all plastic products. Consistency is paramount for manufacturing.

These are typically small, uniform cylinders or spheres, usually in the range of 2 mm to 5 mm in diameter. This small, consistent size ensures they flow smoothly through machinery and melt at a predictable, even rate during processes like injection molding or extrusion.

Understanding the Trade-offs

Choosing a size often involves balancing competing factors. What provides a benefit in one area may be a drawback in another.

Smaller Pellets: Pros and Cons

Smaller pellets offer a more controlled, consistent feed into a system and a higher surface area for faster reaction (burning or dissolving). However, they can produce more dust and may flow too quickly in certain auger designs, leading to over-fuelling.

Larger Pellets: Pros and Cons

Larger pellets are often more durable and produce less dust. They can provide a slower, more prolonged release of energy or nutrients. Their primary drawback is incompatibility with equipment designed for smaller standards.

The Critical Factor of Durability

A pellet's ability to hold its shape without crumbling into dust is a critical quality metric, often related to its size and density. Low-durability pellets create fines (dust and small particles) that can clog augers, reduce airflow in burn pots, and pose a respiratory hazard.

How to Select the Correct Pellet Size

To make the right choice, always start with the requirements of your specific application.

- If your primary focus is residential heating: Look for 6 mm premium-grade wood pellets, as this is the dominant standard for modern pellet stoves.

- If your primary focus is feeding animals: Match the pellet diameter to the animal's species and size—from 2-3 mm for poultry up to 12 mm or more for large livestock.

- If your primary focus is industrial processing (fuel or plastics): You must consult your equipment's technical specifications, as these systems have strict requirements for both size and material quality.

Ultimately, selecting the right pellet size is about ensuring seamless compatibility between the material and the system it serves.

Summary Table:

| Application | Typical Diameter Range | Key Considerations |

|---|---|---|

| Wood Fuel Pellets | 6mm - 8mm | Standard for stoves (ENplus/PFI certified) |

| Animal Feed Pellets | 1mm - 16mm+ | Varies by animal size and species |

| Plastic Pellets (Nurdles) | 2mm - 5mm | Uniformity critical for manufacturing |

Need precise pellet sizing for your laboratory or production process? KINTEK specializes in lab equipment and consumables, serving diverse laboratory needs. Our experts can help you select the perfect pellet specifications to ensure compatibility, efficiency, and safety in your operations. Contact us today to discuss your specific requirements and discover how our solutions can optimize your process!

Visual Guide

Related Products

- XRF & KBR plastic ring lab Powder Pellet Pressing Mold for FTIR

- XRF & KBR steel ring lab Powder Pellet Pressing Mold for FTIR

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Jar Mill with Agate Grinding Jar and Balls

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- Why is a laboratory hydraulic press used for 380 MPa pressure? Master Solid-State Electrolyte Densification

- How does a laboratory hydraulic press ensure the quality of oxide ceramic bulk materials? Achieve Precision Compaction

- What can a hydraulic press be used for? From Industrial Forging to Lab Analysis

- How do laboratory hydraulic presses ensure reliability in PEC sealing? Unlock Stable & Leak-Proof Results

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- Why Use a Laboratory Hydraulic Press for Solid-State Battery Electrolytes? Achieve Maximum Ionic Conductivity

- What is the role of a high-pressure rolling system in ceramic MFC chassis? Ensure Uniformity and Peak Performance

- Why is 1.0 GPa pressure required for nanostructured copper powders? Achieve 96.6% Density with Precision Pressing