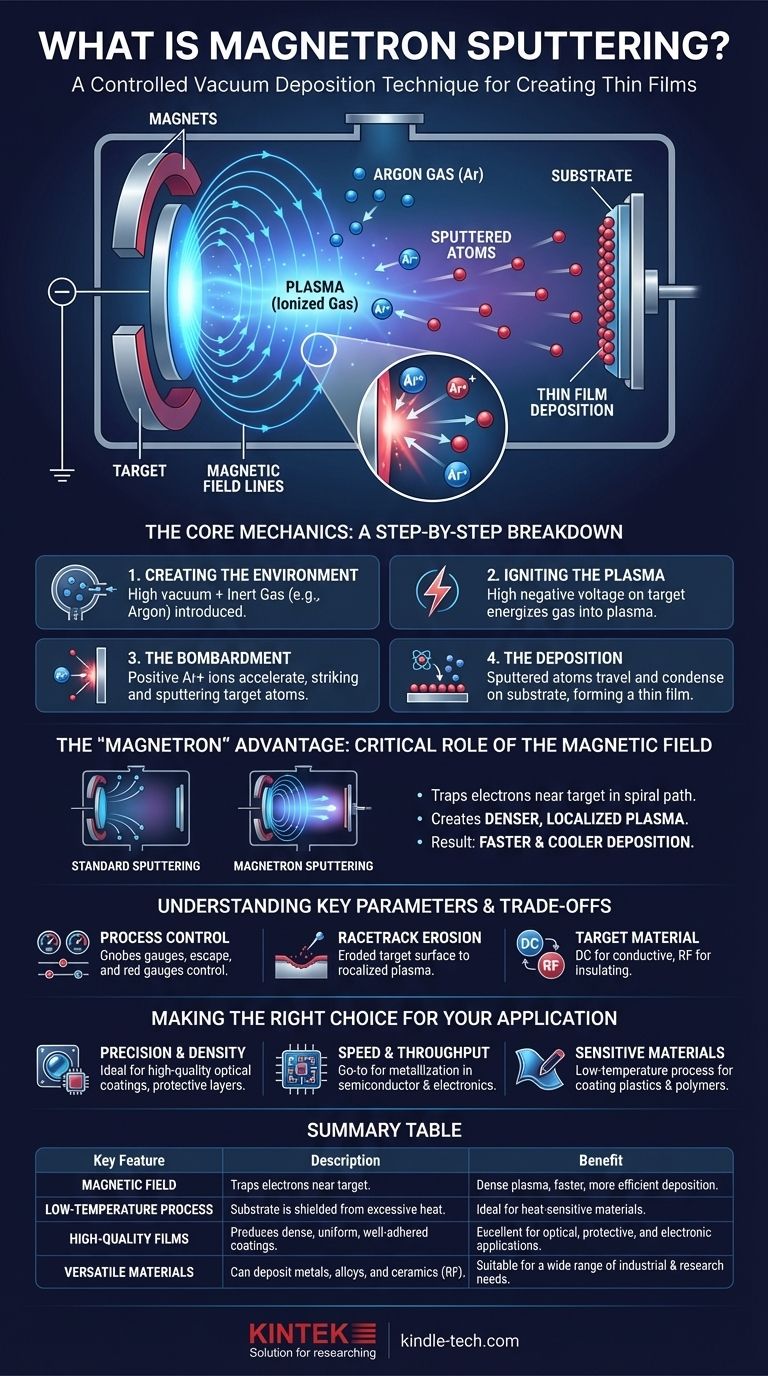

In essence, magnetron sputtering is a highly controlled vacuum deposition technique used to create thin films. It works by generating a plasma of an inert gas, like argon, and using a strategic combination of electric and magnetic fields. The electric field accelerates positive gas ions to bombard a source material (the "target"), physically knocking atoms off its surface, which then travel and deposit onto a substrate to form the coating.

The critical innovation of magnetron sputtering is its use of a magnetic field to trap electrons near the target. This dramatically increases the efficiency of the plasma, resulting in faster deposition rates at lower pressures and temperatures compared to other sputtering methods.

The Core Mechanics: A Step-by-Step Breakdown

To understand how magnetron sputtering works, it's best to visualize it as a sequence of controlled physical events happening within a vacuum chamber.

Step 1: Creating the Environment (Vacuum and Gas)

The entire process occurs in a high-vacuum chamber. This is crucial to remove air and other contaminants that could interfere with the film.

Once a vacuum is achieved, a small, precisely controlled amount of an inert gas, most commonly argon (Ar), is introduced. This gas provides the atoms that will be ionized to start the process.

Step 2: Igniting the Plasma (Electric Field)

A high negative voltage is applied to the target, which is the source material you wish to deposit. The chamber walls or a separate electrode act as the anode.

This strong electric field energizes the argon gas, stripping electrons from the argon atoms and creating a mix of free electrons and positively charged argon ions. This ionized gas is the plasma, often visible as a characteristic glow discharge.

Step 3: The Bombardment (Ion Acceleration)

The positively charged argon ions (Ar+) are strongly attracted to the negatively charged target. They accelerate towards it, striking its surface with significant kinetic energy.

This high-energy collision is a purely physical process. It has enough force to knock out, or "sputter," individual atoms from the target material.

Step 4: The Deposition (Film Formation)

The sputtered atoms are ejected from the target and travel in straight lines through the low-pressure chamber.

When these atoms reach the substrate (the object being coated), they condense on its surface. Over time, this atomic condensation builds up to form a thin, dense, and highly uniform film.

The "Magnetron" Advantage: Why the Magnetic Field is Critical

The addition of a magnetic field is what transforms standard sputtering into the far more effective magnetron sputtering. The magnets are typically placed behind the target.

Trapping Electrons for Maximum Efficiency

The magnetic field is configured to be parallel to the target surface. This field traps the lightweight electrons, forcing them into a spiral, or cycloidal, path close to the target.

Without the magnetic field, electrons would quickly escape to the anode. By trapping them, their path length is increased by orders of magnitude.

Creating a Denser, Localized Plasma

As these trapped electrons spiral near the target, their chances of colliding with and ionizing neutral argon atoms increase dramatically.

This action creates a very dense, self-sustaining plasma concentrated directly in front of the target, right where it is needed most. This is the core reason for the technique's high efficiency.

The Result: Faster and Cooler Deposition

The dense plasma leads to a much higher rate of ion bombardment on the target. This results in significantly faster deposition rates.

Furthermore, because the energetic electrons are confined near the target, the substrate is shielded from excessive electron bombardment. This keeps the substrate cooler, making the process ideal for coating heat-sensitive materials like plastics and polymers.

Understanding the Trade-offs and Key Parameters

While powerful, magnetron sputtering is a complex process with important considerations.

Process Control and Repeatability

The quality of the final film—its density, adhesion, and stress—depends heavily on precise control over parameters like gas pressure, voltage, current, and the strength and shape of the magnetic field.

"Racetrack" Erosion

The magnetic field that confines the plasma is not perfectly uniform. This causes the target to erode more quickly in a specific area, often in an oval or "racetrack" pattern. This can affect process stability and means not all of the target material is used efficiently.

Target Material Requirements

In its most common form, Direct Current (DC) magnetron sputtering, the target material must be electrically conductive. For depositing insulating or ceramic materials, a more complex variation called Radio Frequency (RF) sputtering is required.

Making the Right Choice for Your Application

You can leverage magnetron sputtering for a wide array of applications by understanding its primary benefits.

- If your primary focus is precision and density: This technique is ideal for creating high-quality optical coatings, hard protective layers, and films with specific electrical properties.

- If your primary focus is speed and throughput: The high deposition rates make magnetron sputtering a go-to choice for metallization in the semiconductor and electronics industries.

- If your primary focus is coating sensitive materials: The low-temperature nature of the process allows for depositing high-performance films onto polymers, flexible substrates, and other materials that cannot withstand high heat.

Ultimately, magnetron sputtering provides an exceptional level of control over the growth of thin films at an atomic level.

Summary Table:

| Key Feature | Description | Benefit |

|---|---|---|

| Magnetic Field | Traps electrons near the target. | Creates a dense plasma for faster, more efficient deposition. |

| Low-Temperature Process | Substrate is shielded from excessive heat. | Ideal for coating heat-sensitive materials like plastics. |

| High-Quality Films | Produces dense, uniform, and well-adhered coatings. | Excellent for optical, protective, and electronic applications. |

| Versatile Materials | Can deposit metals, alloys, and ceramics (with RF sputtering). | Suitable for a wide range of industrial and research needs. |

Ready to enhance your lab's capabilities with precision thin films? KINTEK specializes in high-performance lab equipment, including magnetron sputtering systems, to meet the demanding needs of research and production laboratories. Our solutions deliver the control, uniformity, and reliability required for your most critical applications. Contact our experts today to discuss how we can support your specific project goals.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is the process of ALD deposition? Master Atomic-Level Thin Film Coating

- What is the difference between selective laser sintering and electron beam melting? Sintering vs. Melting for Additive Manufacturing

- What environmental conditions does a CVD reaction chamber provide? Optimize Coating Precision at 1050°C

- What is the purpose of a DC bias power supply in growing vertical graphene nanowalls? Control Ion Direction and Growth

- What are the advantages of sputtering deposition? Achieve Superior Thin Films for Demanding Applications

- What is the magnetic field sputtering of a DC magnetron? Unlock Faster, Higher-Quality Coatings

- What is the chemical synthesis of graphene? A Guide to Building High-Quality Sheets via CVD

- What are the advantages of using a Low Pressure Chemical Vapor Deposition (LPCVD) system for HfC coatings?