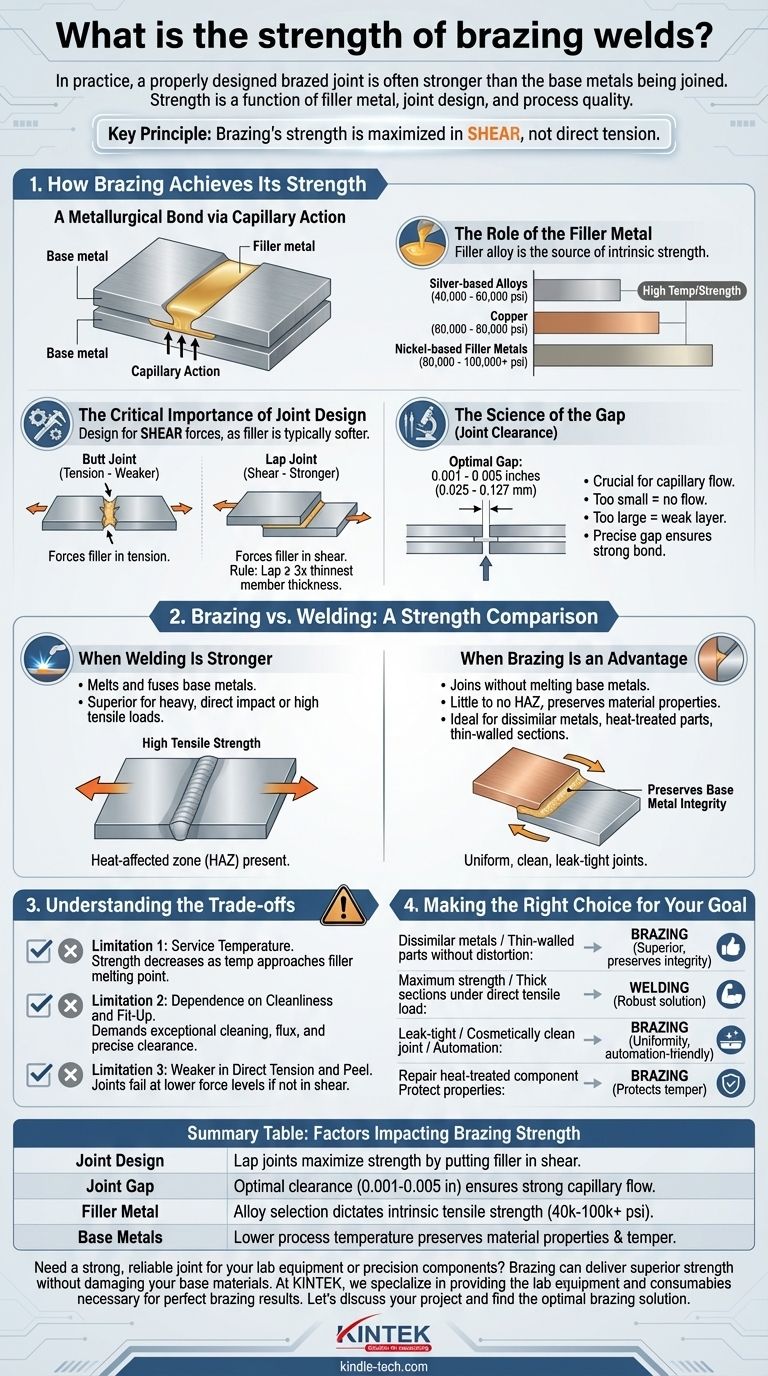

In practice, a properly designed brazed joint is often stronger than the base metals being joined. The strength, however, is not a single value; it's a function of the filler metal used, the design of the joint, and the quality of the brazing process itself. Unlike welding, brazing does not melt the base metals, so its strength is derived from the adhesion and shear strength of the filler alloy within a precisely controlled gap.

The core principle to understand is that brazing's strength is maximized in shear, not direct tension. The question isn't "Is brazing strong?" but rather, "Is my joint designed correctly to leverage the strength of brazing?"

How Brazing Achieves Its Strength

Brazing creates a metallurgical bond by drawing a molten filler metal into the gap between two closely-fitted parts via capillary action. The strength of the final assembly is a result of this system, not just one component.

The Role of the Filler Metal

The filler metal is the source of the joint's intrinsic strength. Different filler alloys have vastly different properties, with tensile strengths ranging from 40,000 psi to over 100,000 psi.

Common silver-based alloys are prized for their versatility and lower brazing temperatures, while copper is used extensively for brazing steel in furnace atmospheres. For high-temperature or high-strength applications, nickel-based filler metals are often the superior choice.

The Critical Importance of Joint Design

The single most important factor in brazing strength is joint design. Because the filler metal is typically softer than the base metals, the joint must be designed to put the filler in shear.

A simple butt joint, which puts the filler in tension, will only be as strong as the filler metal itself. A lap joint, however, creates a larger bonding area and forces the load into shear, dramatically increasing the strength of the assembly. A common rule is to design the lap to be at least three times the thickness of the thinnest member being joined.

The Science of the Gap (Joint Clearance)

Capillary action, the force that draws filler metal into the joint, is highly dependent on the gap between the two parts. The optimal joint clearance for most filler metals is between 0.001 and 0.005 inches (0.025 - 0.127 mm).

If the gap is too small, the filler metal cannot flow into the joint. If the gap is too large, capillary action is lost, and the joint will be a thick, weak layer of filler metal. A precise gap ensures a thin, strong film of filler that creates an exceptionally strong bond.

Brazing vs. Welding: A Strength Comparison

While both processes join metal, they achieve strength in fundamentally different ways, making each suitable for different applications.

When Welding Is Stronger

Welding melts and fuses the base metals together, often with a compatible filler rod. A properly executed weld can be as strong as or even stronger than the base metal itself, especially under direct tensile (pulling) loads.

If your application involves thick sections subject to heavy, direct impact or high tensile stress, and you can manage the heat-affected zone (HAZ) and thermal distortion, welding is often the more robust choice.

When Brazing's Strength Is an Advantage

Brazing's strength shines in its ability to join materials without damaging them. The lower process temperatures (always below the melting point of the base metals) create little to no heat-affected zone, preserving the original temper and metallurgical properties of the parent materials.

This makes brazing the superior process for joining dissimilar metals (like copper to steel), heat-treated components, or very thin-walled sections that would be distorted or destroyed by high-temperature welding. The resulting joint is uniform, clean, and often requires no secondary finishing.

Understanding the Trade-offs

To use brazing effectively, you must understand its limitations. The process is not a universal solution, and overlooking its core requirements can lead to joint failure.

Limitation 1: Service Temperature

A brazed joint's maximum service temperature is limited by the melting point of its filler metal. The joint will lose strength significantly as it approaches this temperature. This must be a primary consideration for any parts intended for high-temperature applications.

Limitation 2: Dependence on Cleanliness and Fit-Up

Brazing is unforgiving of contaminants. The surfaces must be exceptionally clean, and a proper flux must be used to prevent oxidation during heating. Furthermore, as discussed, the process is entirely dependent on maintaining a precise joint clearance. This demands better process control and part preparation than many welding processes.

Limitation 3: Weaker in Direct Tension and Peel

As noted, brazing's strength is in shear. Joints designed to be pulled directly apart (tension) or peeled will fail at much lower force levels. If the joint cannot be designed as a lap or scarf joint to convert the load to shear, brazing may not be the appropriate method.

Making the Right Choice for Your Goal

Selecting the correct joining process requires matching the method's strengths to your application's specific demands.

- If your primary focus is joining dissimilar metals or thin-walled parts without distortion: Brazing is almost always the superior choice, as it preserves the base metals' integrity.

- If your primary focus is maximum strength on thick sections under direct tensile load: Welding is likely the better and more robust solution.

- If your primary focus is creating a leak-tight, cosmetically clean joint on a production line: Brazing's uniformity and suitability for automation make it an excellent choice.

- If your primary focus is repairing a heat-treated component without ruining its properties: Brazing provides the strength you need while protecting the material's temper.

Ultimately, a well-designed brazed joint leverages geometry and metallurgy to create an assembly that is more than the sum of its parts.

Summary Table:

| Factor | Impact on Brazing Strength |

|---|---|

| Joint Design | Lap joints maximize strength by putting filler metal in shear. |

| Joint Gap | Optimal clearance (0.001-0.005 in) ensures strong capillary flow. |

| Filler Metal | Alloy selection dictates intrinsic tensile strength (40,000-100,000+ psi). |

| Base Metals | Lower process temperature preserves material properties and temper. |

Need a strong, reliable joint for your lab equipment or precision components?

Brazing can deliver superior strength without damaging your base materials. At KINTEK, we specialize in providing the lab equipment and consumables necessary for perfect brazing results. Our expertise ensures your joints are designed for maximum shear strength and durability.

Let's discuss your project and find the optimal brazing solution—contact our experts today!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

People Also Ask

- What is a vacuum furnace used for? Unlock Purity in High-Temperature Processing

- Can dissimilar metals be brazed or braze welded? A Guide to Strong, Reliable Joints

- What is brazing in heat treatment? Achieve Superior Joint Quality and Efficiency

- What is the cost of a vacuum brazing furnace? A guide to key factors and investment strategy

- What are vacuum furnaces used for? Unlock Ultimate Material Purity and Performance