In short, the strength of a sintered part is not a single value but a highly engineered outcome. A sintered component can range from moderately strong to possessing mechanical properties that rival those of parts made from wrought or forged metals. This strength is deliberately controlled by manipulating the material's final density, its alloy composition, and any subsequent heat treatments.

The core principle to understand is that the strength of a sintered part is a direct result of design choices. It is a trade-off between the desired mechanical performance and the manufacturing cost, determined almost entirely by how much porosity is removed from the final component.

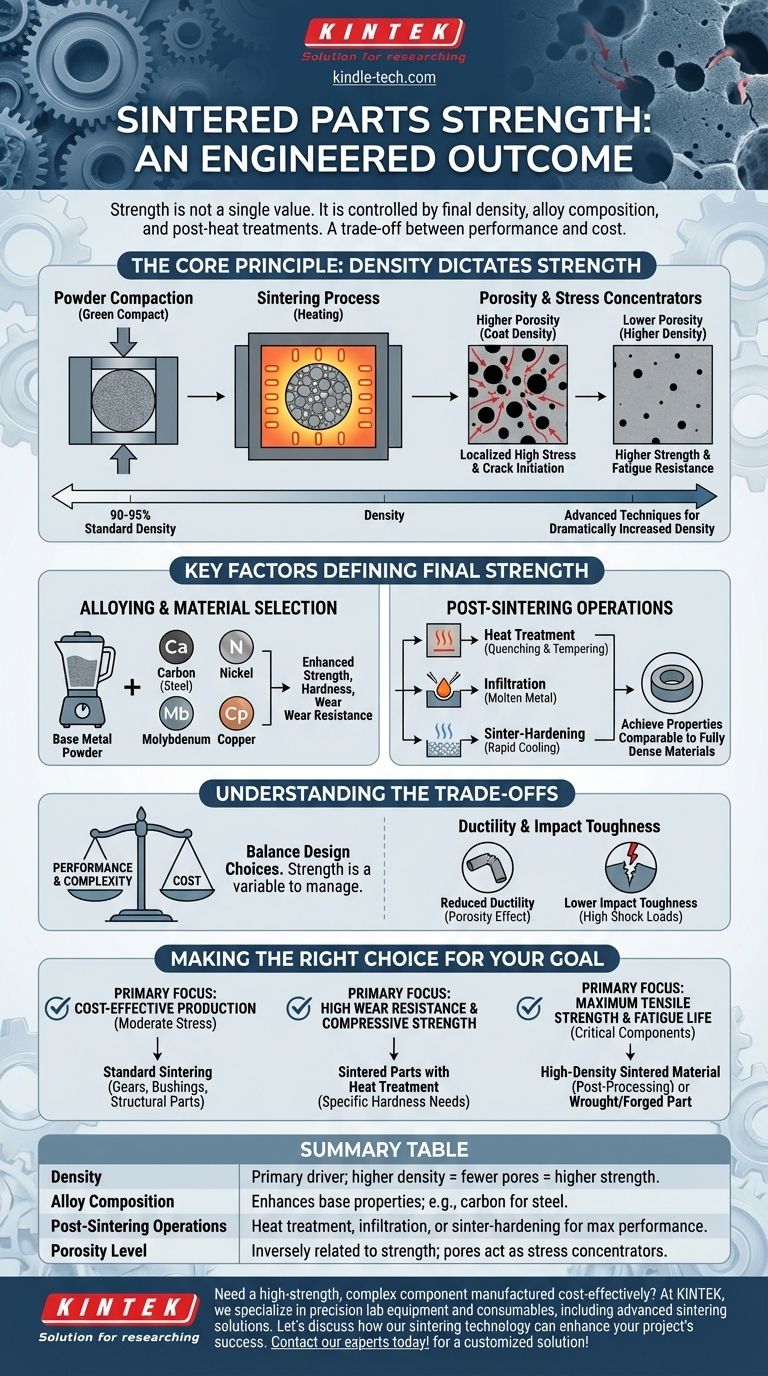

The Core Principle: Density Dictates Strength

The powder metallurgy process, which creates sintered parts, fundamentally differs from melting and casting metal. This difference is the source of both its primary advantage and its most important consideration: porosity.

What is Porosity?

Sintered parts begin as metal powder that is compacted under immense pressure into a desired shape (a "green compact"). This compact is then heated in a furnace, causing the powder particles to fuse together without melting.

Because the particles are fused and not melted, microscopic voids, or pores, remain between them. Porosity is the measure of this empty space within the part's total volume.

The Density-Strength Relationship

The strength of a sintered part is inversely proportional to its level of porosity. A part with higher porosity has less metallic material in any given cross-section to bear a load.

More importantly, these pores act as stress concentrators. Under load, the stress flows around the pores, creating localized points of high stress that can initiate cracks. The fewer pores there are, the stronger and more fatigue-resistant the component will be.

Achieving Higher Density

Standard powder metallurgy processes typically yield parts with a density of 90-95% of the theoretical maximum (a fully solid metal). However, advanced techniques and secondary operations can be used to dramatically increase density and, therefore, strength.

Key Factors That Define Final Strength

Beyond the foundational role of density, two other factors are used to engineer the final properties of a sintered part.

Alloying and Material Selection

Just as with traditional metallurgy, the base metal powder can be blended with other elements to form specific alloys.

Adding carbon to iron powder creates steel. Introducing elements like nickel, molybdenum, or copper can significantly enhance the strength, hardness, and wear resistance of the final sintered steel component.

Post-Sintering Operations

The properties of a part are not finalized once it leaves the sintering furnace. Several secondary processes can be used to achieve properties comparable to fully dense materials.

Key operations include:

- Heat Treatment: Processes like quenching and tempering can be used on sintered steels to dramatically increase hardness and strength.

- Infiltration: The part's pores can be filled by infiltrating them with a molten metal that has a lower melting point, such as copper. This increases density, strength, and pressure tightness.

- Sinter-Hardening: A specialized process where the part is rapidly cooled directly after sintering, combining two steps into one to achieve high hardness and strength efficiently.

Understanding the Trade-offs

Choosing powder metallurgy is an engineering decision that balances performance, complexity, and cost. Its strength is not a limitation but a variable to be managed.

Strength vs. Cost

The primary advantage of sintering is its ability to produce complex, net-shape parts in high volumes with minimal waste and no machining.

Achieving the absolute highest strength and density requires additional processing steps (like forging the sintered preform or using Hot Isostatic Pressing), which increases the cost per part. The goal is often to design a part that is strong enough for its application while retaining the cost benefits of the process.

Ductility and Impact Toughness

The inherent porosity, even at low levels, can reduce a sintered part's ductility (its ability to deform without fracturing) and impact toughness compared to a fully dense wrought or forged equivalent.

This makes sintered parts less suitable for applications involving very high shock loads unless they undergo secondary densification processes.

Making the Right Choice for Your Goal

To determine if a sintered part is strong enough, you must align the process capabilities with your application's specific demands.

- If your primary focus is cost-effective production of complex parts with moderate stress: Standard sintering is an excellent choice, providing sufficient strength for gears, bushings, and structural components in many industries.

- If your primary focus is high wear resistance and compressive strength: Sintered parts, especially with heat treatment, offer exceptional performance and can be tailored for specific hardness requirements.

- If your primary focus is maximum tensile strength and fatigue life for a critical component: You must specify a high-density sintered material, potentially with post-processing, or consider that a wrought or forged part may be the more reliable choice.

Ultimately, viewing sintering not as a single material but as a flexible manufacturing process is the key to leveraging its unique capabilities.

Summary Table:

| Factor | Role in Determining Strength |

|---|---|

| Density | Primary driver; higher density = fewer pores = higher strength. |

| Alloy Composition | Enhances base properties; e.g., carbon for steel, nickel for toughness. |

| Post-Sintering Operations | Heat treatment, infiltration, or sinter-hardening for maximum performance. |

| Porosity Level | Inversely related to strength; pores act as stress concentrators. |

Need a high-strength, complex component manufactured cost-effectively?

At KINTEK, we specialize in precision lab equipment and consumables, including advanced sintering solutions. Our expertise ensures your sintered parts are engineered for optimal strength, durability, and performance, tailored to your specific laboratory or industrial needs.

Let's discuss how our sintering technology can enhance your project's success. Contact our experts today for a customized solution!

Visual Guide

Related Products

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- Does a hydraulic press have heat? How Heated Platens Unlock Advanced Molding and Curing

- How does a vacuum furnace environment influence sintered Ruthenium powder? Achieve High Purity and Theoretical Density

- What causes hydraulic pressure spikes? Prevent System Damage from Hydraulic Shock