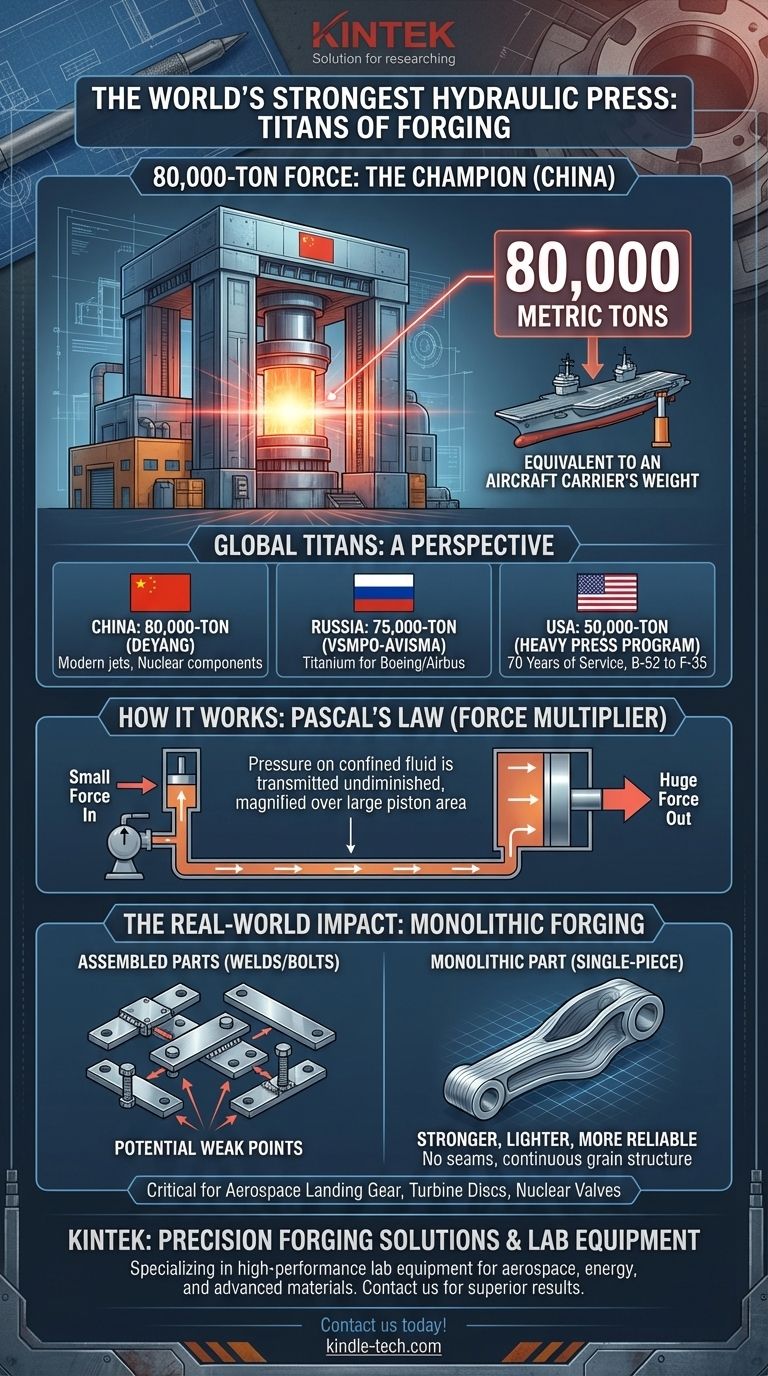

The strongest hydraulic press in the world is an 80,000-ton die-forging press located in Deyang, Sichuan, China. Operated by the China National Erzhong Group (CNEG), this colossal machine, standing over 42 meters (139 feet) tall, is capable of exerting 80,000 metric tons of force—equivalent to the weight of an entire aircraft carrier. It is used to forge massive, single-piece components for a nation's most critical industries, including commercial aviation, aerospace, and nuclear power.

While the sheer force is impressive, the true significance of these mega-presses lies not in their ability to crush, but in their unique power to forge single, flawless metal components that are stronger, lighter, and more reliable than any assembled alternative.

The Titans of Forging: A Global Perspective

The 80,000-ton press is the current champion, but it is one of only a handful of "mega-presses" in the world. These machines are considered strategic national assets, representing the apex of a country's industrial manufacturing capability.

The Reigning Champion: China's 80,000-Ton Press

Completed around 2013, this press is the current record holder. Its primary function is to produce the extremely large, high-strength forgings required for modern wide-body jets, advanced military aircraft, and components for nuclear reactors.

The Russian Powerhouse: VSMPO-AVISMA's 75,000-Ton Press

Located in Verkhnyaya Salda, Russia, this 75,000-ton press is a close competitor. It is a critical part of the global aerospace supply chain, specializing in forging massive titanium components for aircraft manufacturers like Boeing and Airbus.

The American Legends: The 50,000-Ton Heavy Press Program

In the 1950s, the United States Air Force commissioned the Heavy Press Program in response to the discovery of a large German press after WWII. This Cold War initiative resulted in the creation of several presses, two of which are still operational legends.

These 50,000-ton presses, one operated by Wyman-Gordon in Massachusetts and the other by Alcoa in Ohio, have been instrumental in forging critical parts for nearly every major American military and commercial aircraft for over 70 years, from the B-52 bomber to the F-35 fighter and the Boeing 747.

How Is Such Immense Force Possible?

The power of these machines seems almost unbelievable, but it's based on a remarkably straightforward physics principle.

The Principle of Hydraulic Multiplication

At its core, a hydraulic press operates on Pascal's Law. This principle states that pressure applied to a confined fluid is transmitted undiminished throughout the fluid.

Think of it as a force multiplier. A small amount of force applied by a pump to a small volume of hydraulic fluid creates immense pressure. When that pressure acts on the massive surface area of a large piston, the resulting output force is magnified exponentially.

The Anatomy of a Mega-Press

The key to handling these forces is scale. The main cylinders of the 80,000-ton press weigh over 300 tons each. The steel frame, or platens, that holds the workpiece and resists the pressing force is composed of enormous steel castings, each weighing several hundred tons. The entire structure is a monument to material science and engineering.

Understanding the Trade-offs and Challenges

Building and operating a machine of this scale is not without its difficulties. The popular image of a hydraulic press rapidly crushing objects for entertainment is the exact opposite of how these industrial giants work.

Immense Cost and Infrastructure

A mega-press is a multi-billion dollar national project. The machine itself is just one part of a vast ecosystem that includes a dedicated power supply, enormous furnaces to heat the metal billets, and a foundation sunk deep into the bedrock to support its weight and a building to house it.

The Slow, Deliberate Pace of Operation

Forging is not about speed; it is about control. The press moves incredibly slowly, deliberately squeezing a glowing-hot metal billet into a die. This slow application of force allows the metal's crystalline structure to flow and re-form without creating cracks or internal defects. A single pressing cycle can take many minutes.

The Limits of Forging

Even 80,000 tons of force has its limits. The process is constrained by the size of the initial metal billet that can be produced and heated, the complexity of the die, and the physical properties of the metal alloy being forged.

Why This Power Matters: The Real-World Impact

The ultimate goal of this extreme engineering is to create components with uncompromising structural integrity.

The Advantage of Monolithic Parts

These presses create monolithic (single-piece) components. Forging a massive aircraft wing spar or landing gear beam from a single piece of metal eliminates the need for welds, bolts, or seams.

Every seam or joint is a potential point of failure. By creating a single, continuous-grain structure, monolithic forging produces parts that are significantly stronger, lighter, and more resistant to fatigue than any multi-part assembly.

Forging for Aerospace and Energy

This capability is non-negotiable for modern aerospace. The main landing gear beam for an Airbus A380 or the central wing box for a fighter jet must withstand incredible stress цикles. Forging them as a single piece is हाथ-down the safest and most reliable manufacturing method.

Likewise, in the energy sector, these presses forge a turbine-disk for a power plant or a critical valve body for a nuclear reactor, where failure is not an option.

Making the Right Choice for Your Goal

Understanding these machines is about appreciating the specific problems they solve.

- If your primary focus is on pure engineering capability: The 80,000-ton press in China represents the current pinnacle of applied hydraulic force for industrial forging.

- If your primary focus is on historical significance: The U.S. Air Force's 50,000-ton Heavy Press Program of the 1950s is the foundational story of modern mega-forging.

- If your primary focus is on material science: These presses are tools that enable the creation of monolithic components with superior strength-to-weight ratios, which is impossible with other manufacturing methods.

These machines are not just about brute force; they are about achieving a level of material perfection that underpins our most advanced and critical technologies.

Summary Table:

| Attribute | Details |

|---|---|

| Strongest Press | 80,000-ton die-forging press (China National Erzhong Group) |

| Key Competitors | Russian 75,000-ton press; US 50,000-ton Heavy Press Program |

| Primary Use | Forging monolithic components for aerospace, aviation, and nuclear power |

| Key Advantage | Creates single-piece parts stronger and lighter than assembled alternatives |

Need precision forging solutions or robust lab equipment? KINTEK specializes in providing high-performance lab equipment and consumables tailored to demanding industrial and research applications. Whether you're in aerospace, energy, or advanced materials development, our expertise ensures you have the right tools for superior results. Contact us today to discuss how we can support your project's success!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation