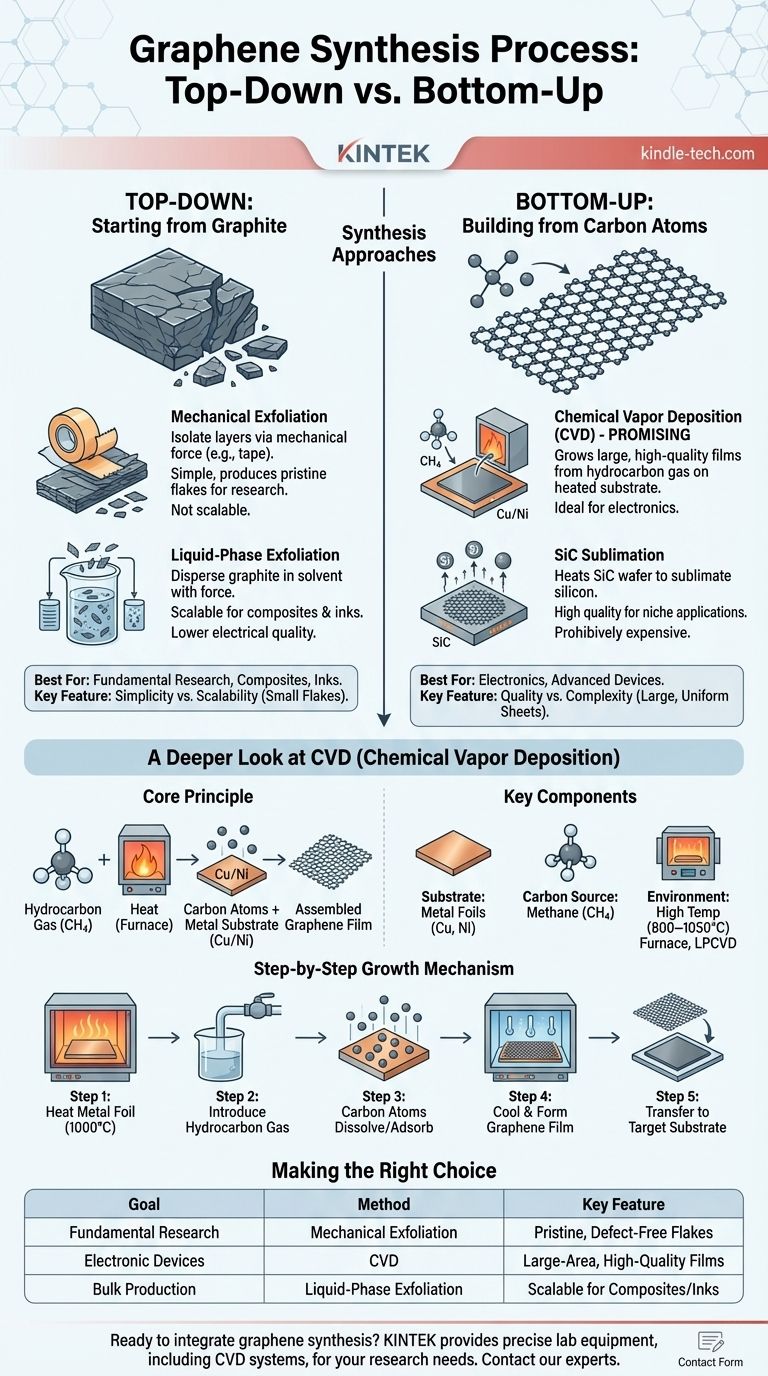

The synthesis of graphene is broadly divided into two categories: top-down methods that break down graphite, and bottom-up methods that build the material from carbon atoms. Of these, Chemical Vapor Deposition (CVD) stands out as the most promising and widely adopted technique for producing the large-area, high-quality graphene films required for advanced electronics.

The central challenge in graphene synthesis is managing the trade-off between quality, scale, and cost. While simple exfoliation can produce pristine flakes for research, only bottom-up methods like Chemical Vapor Deposition (CVD) can reliably grow the large, uniform sheets needed for industrial applications.

The Two Fundamental Approaches to Graphene

To understand modern graphene production, it is essential to distinguish between the two core philosophies for creating it. Each serves a different purpose and comes with its own set of advantages and limitations.

Top-Down: Starting from Graphite

This approach involves separating the individual layers of graphene from a source material, most commonly graphite. It is conceptually similar to shaving layers off a larger block.

The primary methods are mechanical exfoliation, famously used to first isolate graphene with adhesive tape, and liquid-phase exfoliation, which uses chemical or mechanical forces to disperse graphite into graphene flakes in a solvent.

These methods are effective for fundamental research (mechanical) or creating graphene-based composites and inks (liquid-phase), but they typically yield small flakes and struggle to produce the large, continuous sheets needed for electronics.

Bottom-Up: Building from Carbon Atoms

The bottom-up strategy involves constructing the graphene lattice atom by atom from a carbon-containing source. This provides far greater control over the final product's quality and size.

The definitive bottom-up technique is Chemical Vapor Deposition (CVD). This method is the focus of most commercial and advanced research efforts because it is capable of growing a continuous, single-atom-thick film over large areas.

A Deeper Look at Chemical Vapor Deposition (CVD)

CVD is the leading technique for scalable, high-quality graphene synthesis. The process relies on a chemical reaction on a heated substrate to assemble a film of graphene.

The Core Principle of CVD

The process involves introducing a hydrocarbon gas into a high-temperature furnace containing a metal substrate. At extreme heat, the gas decomposes, freeing carbon atoms that then assemble into the honeycomb lattice of graphene on the metal surface.

Key Components of the CVD Process

Successful CVD synthesis depends on the precise control of several critical components.

- The Substrate: Transition metals like copper (Cu) or nickel (Ni) foils act as a catalytic surface. Carbon atoms from the gas source first diffuse into or adsorb onto this metal surface.

- The Carbon Source: The most common and reliable carbon source is methane gas (CH₄) due to its simple structure. Other sources, such as petroleum asphalt, exist but are more difficult to manage.

- The Environment: The reaction takes place inside a furnace at very high temperatures, typically between 800–1050 °C. Most systems use low-pressure CVD (LPCVD) to prevent unwanted side reactions and ensure the graphene film grows with a uniform thickness.

The Step-by-Step Growth Mechanism

- A metal foil substrate is placed inside a sealed reaction chamber and heated to around 1000 °C.

- The hydrocarbon gas is introduced into the chamber. The high temperature breaks the gas molecules apart, releasing carbon atoms.

- These carbon atoms dissolve into the metal substrate (in the case of nickel) or adsorb onto its surface (in the case of copper).

- As the chamber is cooled, the carbon atoms' solubility in the metal decreases, causing them to precipitate out onto the surface and form a continuous film of graphene.

- Finally, the graphene film must be carefully transferred from the metal foil to a target substrate (like silicon) for use in a device.

Understanding the Trade-offs

No single synthesis method is perfect for every application. The choice of technique is always a matter of balancing competing priorities.

CVD: Quality vs. Complexity

CVD produces the highest-quality, largest-area graphene films, making it ideal for electronics. However, the process requires expensive, specialized equipment, high temperatures, and a delicate transfer step that can introduce wrinkles, tears, and contaminants into the final film.

Exfoliation: Simplicity vs. Scalability

Mechanical exfoliation is simple and produces pristine, defect-free graphene flakes, but it is a purely manual process unsuitable for any form of mass production. Liquid-phase exfoliation is highly scalable for bulk materials but results in lower electrical quality, making it unfit for high-performance electronics.

SiC Sublimation: High Cost for Niche Applications

Another bottom-up method involves heating a silicon carbide (SiC) wafer until the silicon sublimates (turns to gas), leaving behind a layer of graphene. This creates high-quality graphene directly on a semiconductor-compatible wafer but is prohibitively expensive for most applications.

Making the Right Choice for Your Goal

Selecting the correct synthesis method is entirely dependent on the intended application of the graphene.

- If your primary focus is fundamental research on pristine graphene: Mechanical exfoliation is the standard for producing the highest-quality, albeit small, flakes for scientific study.

- If your primary focus is developing electronic or photonic devices: Chemical Vapor Deposition (CVD) is the most effective method for growing the large, uniform, and high-quality films necessary for device fabrication.

- If your primary focus is bulk production for composites or inks: Liquid-phase exfoliation offers a scalable, lower-cost pathway where elite electrical performance is not the main priority.

Ultimately, the power of graphene is only unlocked by choosing the synthesis technique that aligns directly with the demands of your specific project.

Summary Table:

| Method | Key Feature | Best For |

|---|---|---|

| Chemical Vapor Deposition (CVD) | Builds large-area, high-quality films | Electronics, advanced devices |

| Mechanical Exfoliation | Produces pristine, defect-free flakes | Fundamental research |

| Liquid-Phase Exfoliation | Scalable for bulk materials | Composites, conductive inks |

Ready to integrate graphene synthesis into your lab workflow? The right equipment is critical for success. KINTEK specializes in providing the precise, high-performance lab equipment and consumables needed for advanced material synthesis, including CVD systems. Our expertise ensures you have the reliable tools to achieve your research and development goals in electronics, composites, and more. Contact our experts today to discuss your specific graphene synthesis needs!

Visual Guide

Related Products

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Graphite Vacuum Furnace High Thermal Conductivity Film Graphitization Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What are the main advantages of Chemical Vapor Deposition (CVD)? Achieve Precision Coating for Complex Geometries

- What function does CVD equipment serve in rhodium-modified coatings? Achieve Deep Diffusion and Microstructural Precision

- What is a CVD tube furnace? A Complete Guide to Thin-Film Deposition

- What is the floating catalyst method? A Guide to High-Yield CNT Production

- How high of temperature do carbon nanotubes in air have the ability to sustain? Understanding the Oxidation Limit