The temperature for sintering is not a single value but is fundamentally dependent on the material being processed. As a general principle, sintering occurs at temperatures greater than 60% of the material's absolute melting temperature (Tm). For example, some metal powders can be sintered around 630°C (1166°F), while high-performance ceramics like Zirconia require temperatures closer to 1,500°C (2732°F) to achieve full density.

Sintering is a balancing act. The temperature must be high enough to energize atoms to diffuse and fuse particles together, yet it must remain strictly below the material’s melting point. The precise temperature is chosen to achieve a specific goal, most often maximizing the final part's density.

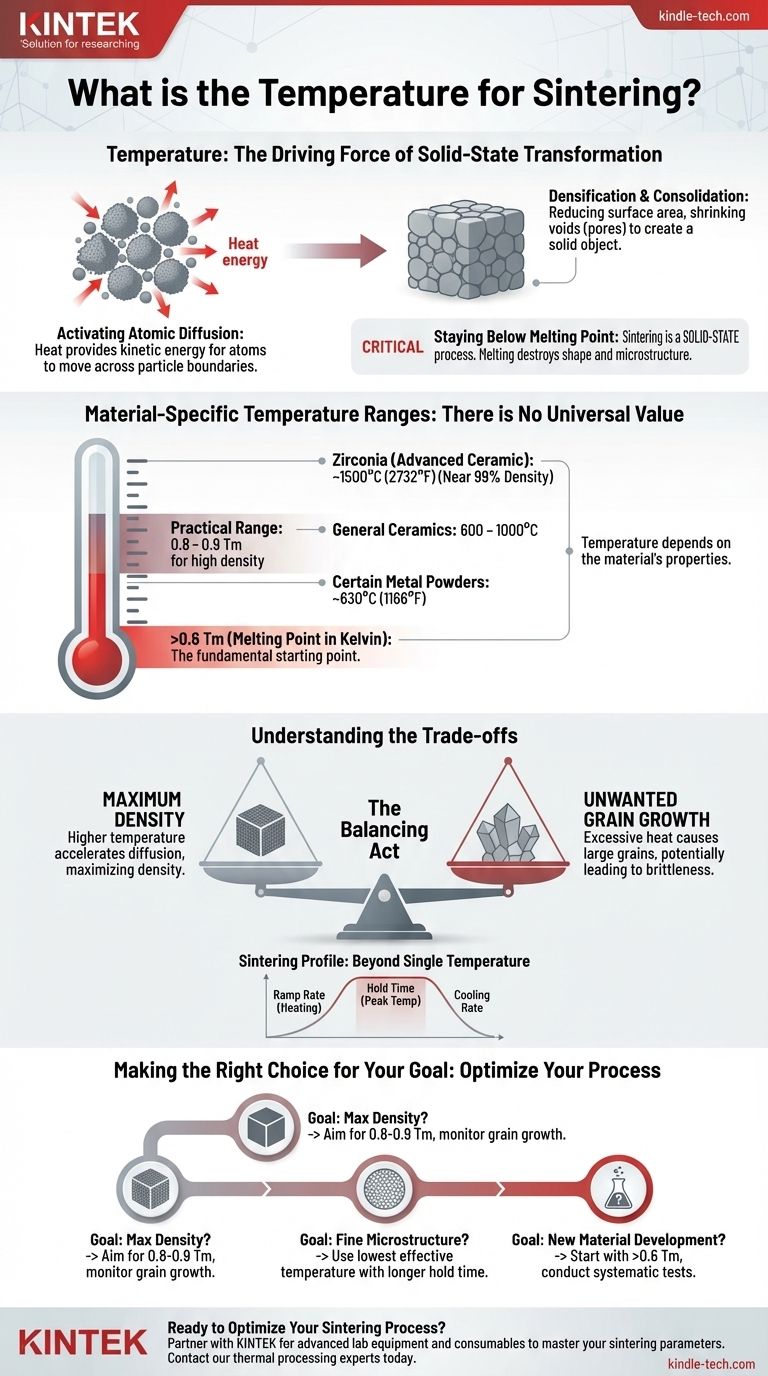

Why Temperature is the Driving Force of Sintering

Temperature isn't just a setting; it's the energy that enables the entire solid-state transformation of a loose powder into a dense, solid object.

Activating Atomic Diffusion

Sintering works by promoting atomic diffusion. Heat gives the atoms within the powder particles enough kinetic energy to move across the boundaries where particles touch, effectively welding them together.

Without sufficient heat, atoms remain locked in place, and the powder will not consolidate into a solid mass.

The Goal: Densification and Consolidation

The movement of atoms works to reduce the total surface area of the powder mass. This process shrinks the voids (pores) between particles, causing the entire component to become denser and stronger.

The higher the temperature, the faster this diffusion and densification process occurs.

Staying Below the Melting Point

It is critical to understand that sintering is a solid-state process. The material must never reach its melting point.

If the material melts, you are casting or brazing, not sintering. This would destroy the component's shape and internal microstructure.

Material-Specific Temperature Ranges

The "right" temperature is dictated entirely by the material's properties. There is no universal number.

The General Guideline: >0.6 Tm

The most reliable starting point for any material is to calculate 0.6 times its absolute melting temperature (Tm), measured in Kelvin. Sintering typically begins above this threshold.

However, optimal temperatures are often much higher, in the range of 0.8 to 0.9 Tm, to achieve high density in a reasonable amount of time.

Examples Across Materials

The practical range is vast, highlighting the importance of material choice:

- Certain Metal Powders: May be sintered at temperatures as low as 630°C.

- General Ceramics: Often fall within a broad range of 600 – 1000°C.

- Zirconia (Advanced Ceramic): Requires very high temperatures, around 1,500°C, to achieve its maximum theoretical density of nearly 99%.

Understanding the Trade-offs

Selecting a sintering temperature is about managing competing factors. Simply choosing the highest possible temperature is not always the best approach.

Temperature vs. Density

Generally, a higher sintering temperature results in a denser final part because of accelerated atomic diffusion. The Zirconia example shows that firing at 1,500°C, well above its transformation temperature of 1,100°C, is done specifically to maximize density.

The Risk of Grain Growth

The primary trade-off for high temperature is unwanted grain growth. While heat fuses particles, it can also cause the crystalline grains within the material to grow excessively large.

Large grains can often make the final part more brittle and mechanically weaker. This is a critical factor to control for high-performance components.

Beyond a Single Temperature: The Sintering Profile

True process control involves more than just the peak temperature. The entire heating and cooling cycle is critical.

Factors like the ramp rate (how fast you heat up), hold time (how long you stay at peak temperature), and cooling rate all have a significant impact on the final density, grain size, and mechanical properties of the sintered part.

Making the Right Choice for Your Goal

The optimal temperature is a function of your material and your desired outcome. Use these principles to guide your process.

- If your primary focus is maximum density: Aim for the higher end of the material's recommended range (e.g., 0.8-0.9 Tm), but monitor for excessive grain growth that could harm mechanical properties.

- If your primary focus is preserving a fine microstructure: Use the lowest temperature that achieves the necessary consolidation, potentially paired with a longer hold time to allow diffusion to occur without encouraging rapid grain growth.

- If you are developing a process for a new material: Begin with the

>0.6 Tmrule of thumb as a starting point and conduct systematic tests, varying temperature and hold time to map their effects on density and microstructure.

Understanding these core principles transforms the process from following a recipe to engineering a specific, desired material outcome.

Summary Table:

| Material Type | Typical Sintering Temperature Range | Key Consideration |

|---|---|---|

| Certain Metal Powders | ~630°C (1166°F) | Lower end of the temperature spectrum. |

| General Ceramics | 600 – 1000°C | Broad range based on specific composition. |

| Zirconia (Advanced Ceramic) | ~1500°C (2732°F) | High temperature required for near-full density. |

| General Guideline | >60% of Material's Melting Point (Tm) | A fundamental starting point for any material. |

Ready to Optimize Your Sintering Process?

Selecting the precise temperature profile is critical for achieving the desired density, strength, and microstructure in your sintered components. The experts at KINTEK specialize in providing the advanced lab equipment and consumables necessary for precise thermal processing.

We understand the delicate balance between temperature, density, and grain growth. Whether you are working with novel metal powders or high-performance ceramics, our solutions are designed to help you achieve consistent, high-quality results.

Let KINTEK be your partner in materials development.

Contact our thermal processing experts today to discuss how our equipment can help you master your sintering parameters and meet your specific material goals.

Visual Guide

Related Products

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What conditions does a vacuum hot press provide for Al2O3/ZrO2 sintering? Achieve 1550°C and 30 MPa Densification

- What are the primary advantages of using a vacuum hot pressing sintering furnace? Maximize Density in B4C-CeB6 Ceramics

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- How does a vacuum hot press sintering furnace facilitate a high-quality bond? Achieve Superior Metallurgical Coating

- What are the advantages of vacuum sintering? Achieve Superior Purity, Strength, and Performance