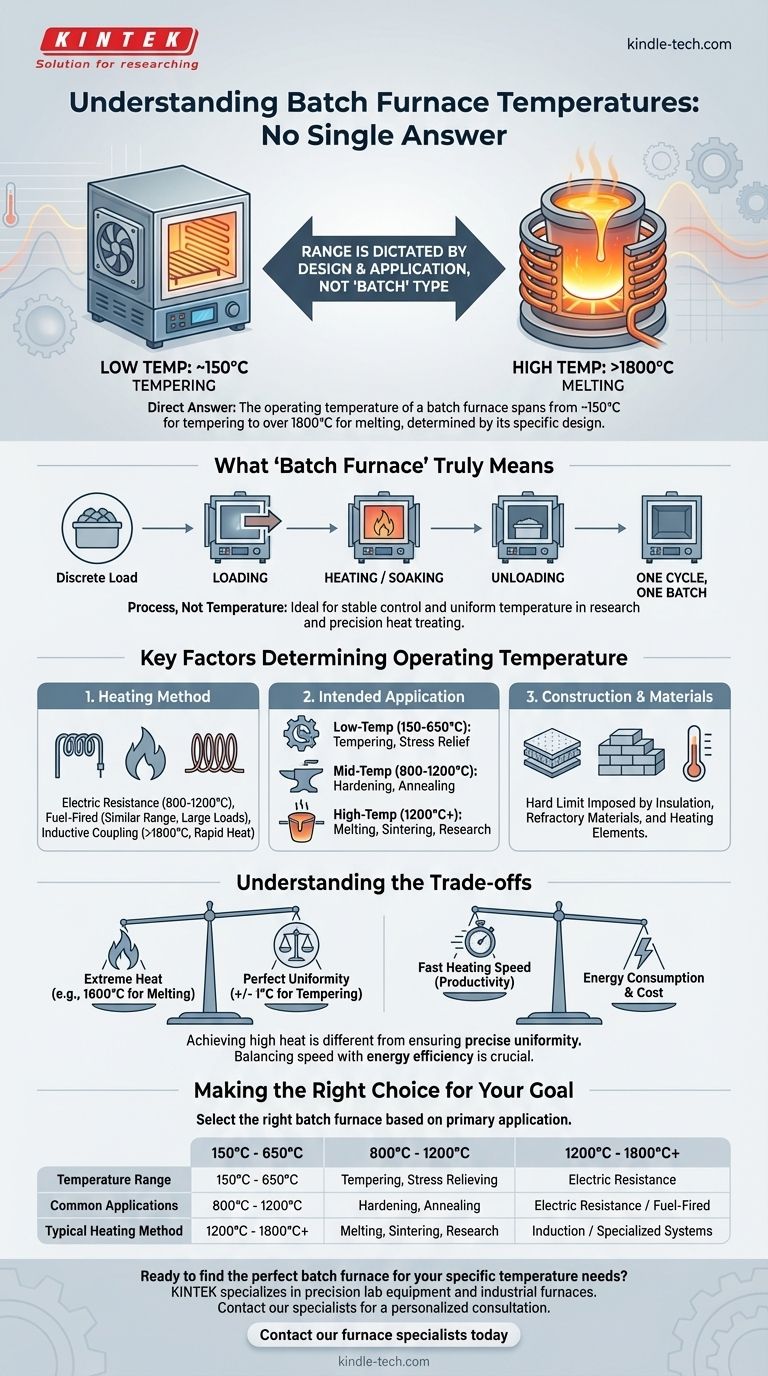

To be direct, there is no single temperature for a batch type furnace. The operating temperature is dictated entirely by the furnace's specific design and its intended industrial or research application, with a range spanning from as low as 150°C for tempering processes to over 1800°C for melting advanced materials.

The term "batch furnace" describes a process—heating materials in discrete groups—not a specific temperature capability. The furnace's maximum temperature is ultimately determined by its heating method (e.g., electric induction, resistance, or fuel combustion) and the materials it is built to handle.

What "Batch Furnace" Truly Means

A batch furnace is defined by its operational method, not its temperature. It processes a single, discrete load of material at a time.

The Batch Process Explained

The entire cycle of loading, heating, soaking at temperature, and unloading is performed on one "batch" before the next one begins. This contrasts with continuous furnaces, where materials are constantly fed through a heated chamber on a conveyor.

Key Characteristics

This batch-style operation is ideal for applications requiring stable control and uniform temperature throughout the entire workload, which is a common need in scientific research and precision heat treating.

Key Factors Determining Operating Temperature

A batch furnace's temperature capability is a result of its engineering and purpose. Three primary factors dictate its operational range.

Heating Method

The technology used to generate heat is the single most significant factor.

- Electric Resistance: Coils or elements heat up when electricity passes through them. These are common for heat treating and research, often operating in the 800°C to 1200°C range.

- Fuel-Fired (Combustion): Gas or oil is burned to generate heat. These are industrial workhorses for large loads and can reach similar temperatures, though precise control can be more complex.

- Inductive Coupling: An electromagnetic coil induces current within the material itself, generating intense and rapid heat. As noted, an induction furnace is a prime example of a high-temperature batch system, capable of reaching 1800°C or more for melting metals.

Intended Application

Furnaces are built for a purpose, which defines their temperature requirements.

- Low-Temperature Processes (~150°C - 650°C): Used for tempering steel, stress relieving, and aging aluminum.

- Mid-Temperature Processes (~800°C - 1200°C): Required for hardening, annealing, and normalizing metals like steel.

- High-Temperature Processes (1200°C+): Necessary for melting metals, sintering ceramics, and advanced materials research.

Construction and Materials

The furnace's physical construction imposes a hard limit on its temperature. The type of insulation, the refractory materials lining the chamber, and the composition of the heating elements all have maximum service temperatures they cannot exceed.

Understanding the Trade-offs

Choosing a furnace involves balancing competing characteristics. A furnace optimized for extreme heat may not be the best choice for processes requiring absolute precision at lower temperatures.

Temperature vs. Uniformity

Achieving extremely high temperatures is a different engineering challenge than maintaining perfect temperature uniformity. A furnace designed to melt alloys at 1600°C is built for raw power and containment. A different furnace designed to temper parts at 250°C might have sophisticated airflow systems to ensure every part is within +/- 1°C of the setpoint—a level of uniformity that is much harder to achieve at extreme temperatures.

Heating Speed vs. Energy Use

Features like fast heating speed are valuable for productivity but often come at the cost of higher energy consumption. Modern furnaces use advanced insulation and control systems to balance performance with energy-saving goals.

Making the Right Choice for Your Goal

To select the right type of batch furnace, you must first define your primary application.

- If your primary focus is low-temperature heat treating (e.g., tempering, stress relief): You need a furnace with excellent temperature uniformity and stable control, likely a fan-circulated electric resistance model.

- If your primary focus is hardening or annealing common steels: A standard electric resistance or fuel-fired batch furnace operating up to 1200°C is the industry standard.

- If your primary focus is melting metals or high-temperature research: You require a specialized system, such as an induction furnace, capable of reaching 1800°C or higher.

Ultimately, the temperature of a batch furnace is a specification, not a definition.

Summary Table:

| Temperature Range | Common Applications | Typical Heating Method |

|---|---|---|

| 150°C - 650°C | Tempering, Stress Relieving | Electric Resistance |

| 800°C - 1200°C | Hardening, Annealing | Electric Resistance / Fuel-Fired |

| 1200°C - 1800°C+ | Melting, Sintering, Research | Induction / Specialized Systems |

Ready to find the perfect batch furnace for your specific temperature needs?

KINTEK specializes in precision lab equipment and industrial furnaces. Whether you require stable, uniform heat for tempering or extreme temperatures for advanced materials research, our experts will help you select the ideal system for your application, balancing performance, energy efficiency, and cost.

Contact our furnace specialists today for a personalized consultation and discover how KINTEK can enhance your laboratory or production process.

Visual Guide

Related Products

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- 1200℃ Muffle Furnace Oven for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is the impact factor of powder metallurgy progress? A 2022 Analysis & Context

- What is the boiling point of THC under a vacuum? A Guide to Safe Distillation

- What are the challenges of welding stainless steel? Overcome Warping, Sensitization, and Contamination

- What is a sputtering machine? A Guide to High-Quality Thin Film Deposition

- What is sputtering technology? A Guide to Precision Thin Film Deposition