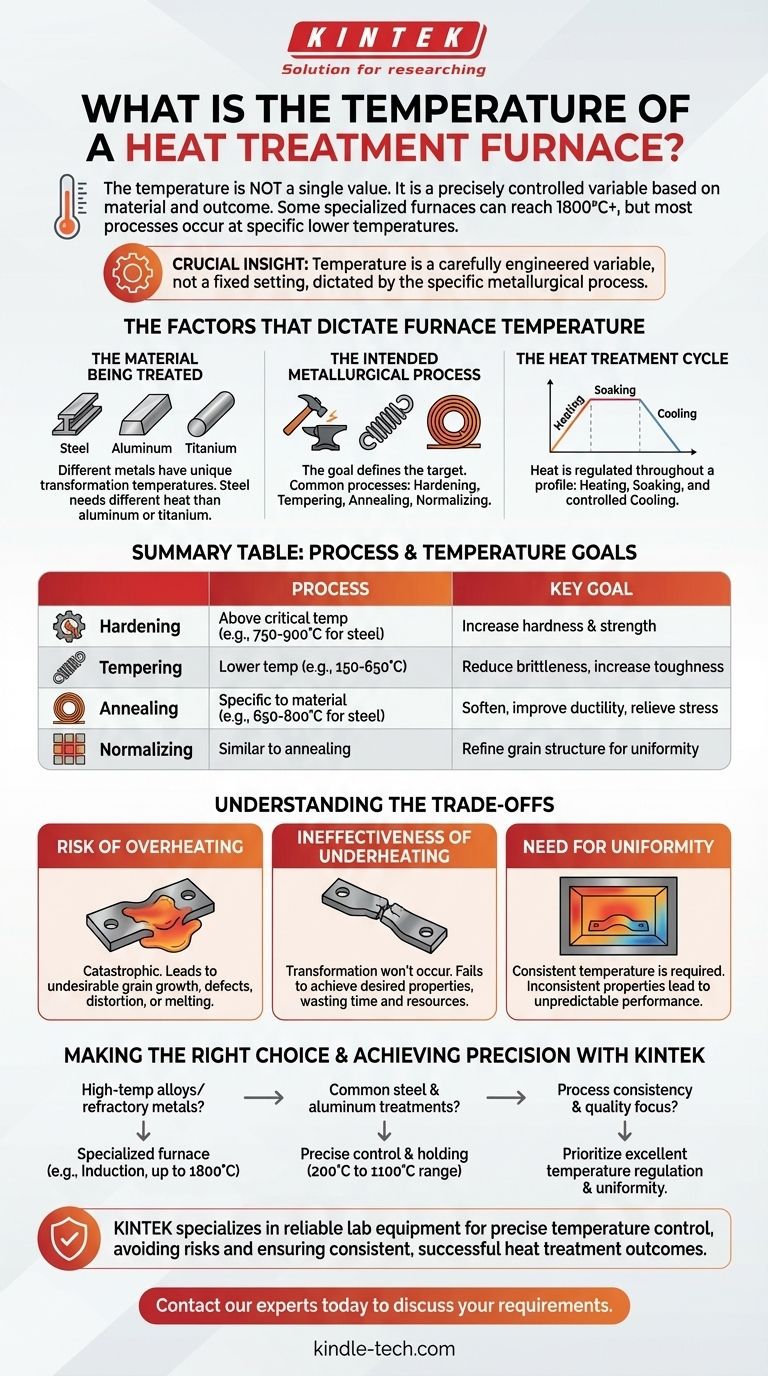

The temperature of a heat treatment furnace is not a single value but is precisely controlled based on the material being treated and the desired outcome. While some specialized furnaces, such as induction furnaces, can reach temperatures of 1800°C (3272°F) or higher, most heat treatment processes occur at specific, lower temperatures required for a particular metallurgical transformation.

The crucial insight is that a heat treatment furnace's temperature is a carefully engineered variable, not a fixed setting. The correct temperature is dictated entirely by the specific process—such as hardening, annealing, or tempering—that a particular metal alloy requires to achieve its target properties.

The Factors That Dictate Furnace Temperature

A furnace's temperature is a tool used to alter the internal microstructure of a material. The specific temperature, and how long the material is held there, is determined by several critical factors.

The Material Being Treated

Different metals and alloys have vastly different transformation temperatures. For example, the temperatures required to heat treat steel are fundamentally different from those needed for aluminum or titanium alloys due to their unique metallurgy and melting points.

The Intended Metallurgical Process

The goal of the heat treatment defines the target temperature. Common processes include:

- Hardening: Heating a steel above its critical temperature to change its crystal structure, followed by rapid cooling (quenching).

- Tempering: Reheating a hardened part to a lower temperature to reduce brittleness and increase toughness.

- Annealing: Heating a material to a specific temperature and holding it there to soften it, improve ductility, and relieve internal stresses.

- Normalizing: Similar to annealing but with a different cooling rate to produce a more uniform and refined grain structure.

The Heat Treatment Cycle

The process is not just about reaching a peak temperature. Heat is regulated throughout a "thermal profile" or cycle.

- Heating Period: More energy is supplied to bring the material and the furnace up to the target temperature.

- Soaking Period: Once the target temperature is reached, it is held constant for a specific duration to ensure the entire part undergoes the desired transformation.

- Cooling Period: The material is cooled at a controlled rate, which is just as critical as the heating itself for achieving the final properties.

Understanding the Trade-offs of Temperature Control

Achieving the correct temperature is non-negotiable for successful heat treatment. Deviations in either direction can lead to failed parts, wasted energy, and compromised safety.

The Risk of Overheating

Exceeding the target temperature, even for a short time, can be catastrophic. It can lead to undesirable grain growth (making the material weaker), surface defects, distortion, or even partial melting of the component.

The Ineffectiveness of Underheating

Failing to reach the required temperature means the intended metallurgical transformation will not occur. An underheated part will not achieve the desired hardness, softness, or stress relief, rendering the entire process ineffective and a waste of time and resources.

The Need for Uniformity

The stated temperature must be consistent throughout the entire furnace chamber. Hot or cold spots can cause a single part to have inconsistent properties, leading to unpredictable performance and potential failure in service.

Making the Right Choice for Your Goal

Selecting or operating a furnace requires matching its capabilities to the specific process requirements. The maximum temperature is only one part of the equation.

- If your primary focus is processing high-temperature alloys or refractory metals: You will need a specialized furnace, such as an induction furnace, capable of reaching extreme temperatures like 1800°C.

- If your primary focus is common steel and aluminum treatments: The critical factor is not the absolute maximum temperature but the furnace's ability to precisely control and hold temperatures in the 200°C to 1100°C range.

- If your primary focus is process consistency and quality: Prioritize a furnace with excellent temperature regulation and uniformity to ensure every part adheres to the exact thermal profile required.

Ultimately, the right temperature is the one demanded by the specific metallurgical process you need to perform.

Summary Table:

| Process | Typical Temperature Range | Key Goal |

|---|---|---|

| Hardening | Above critical temperature (e.g., 750-900°C for steel) | Increase hardness and strength |

| Tempering | Lower temperature (e.g., 150-650°C) | Reduce brittleness, increase toughness |

| Annealing | Specific to material (e.g., 650-800°C for steel) | Soften, improve ductility, relieve stress |

| Normalizing | Similar to annealing | Refine grain structure for uniformity |

Achieve Precise Metallurgical Transformations with KINTEK

Selecting the right furnace temperature is critical for achieving the exact material properties you need. KINTEK specializes in providing reliable lab equipment and consumables designed for precise temperature control and uniformity, ensuring your heat treatment processes—from hardening steel to annealing aluminum—are consistently successful.

Our expertise helps you avoid the risks of overheating, underheating, and inconsistent results, saving you time, resources, and ensuring the highest quality outcomes for your laboratory.

Contact our experts today to discuss your specific heat treatment requirements and find the perfect furnace solution for your lab.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- What is the temperature of a quartz tube furnace? Master the Limits for Safe, High-Temp Operation

- What is a vertical tube furnace? Leverage Gravity for Superior Uniformity and Process Control

- Why does heating increase temperature? Understanding the Molecular Dance of Energy Transfer

- What is quartz tube heating? Achieve Instant, Targeted Heat with Infrared Radiation

- What is the process of annealing tubes? Achieve Optimal Softness and Ductility for Your Tubing