The temperature for pyrolysis is not a single figure but a wide range, typically falling between 400°C and 900°C (750°F to 1650°F). However, the initial decomposition of some materials, like wood, can begin at much lower temperatures, around 200°C to 300°C (390°F to 570°F).

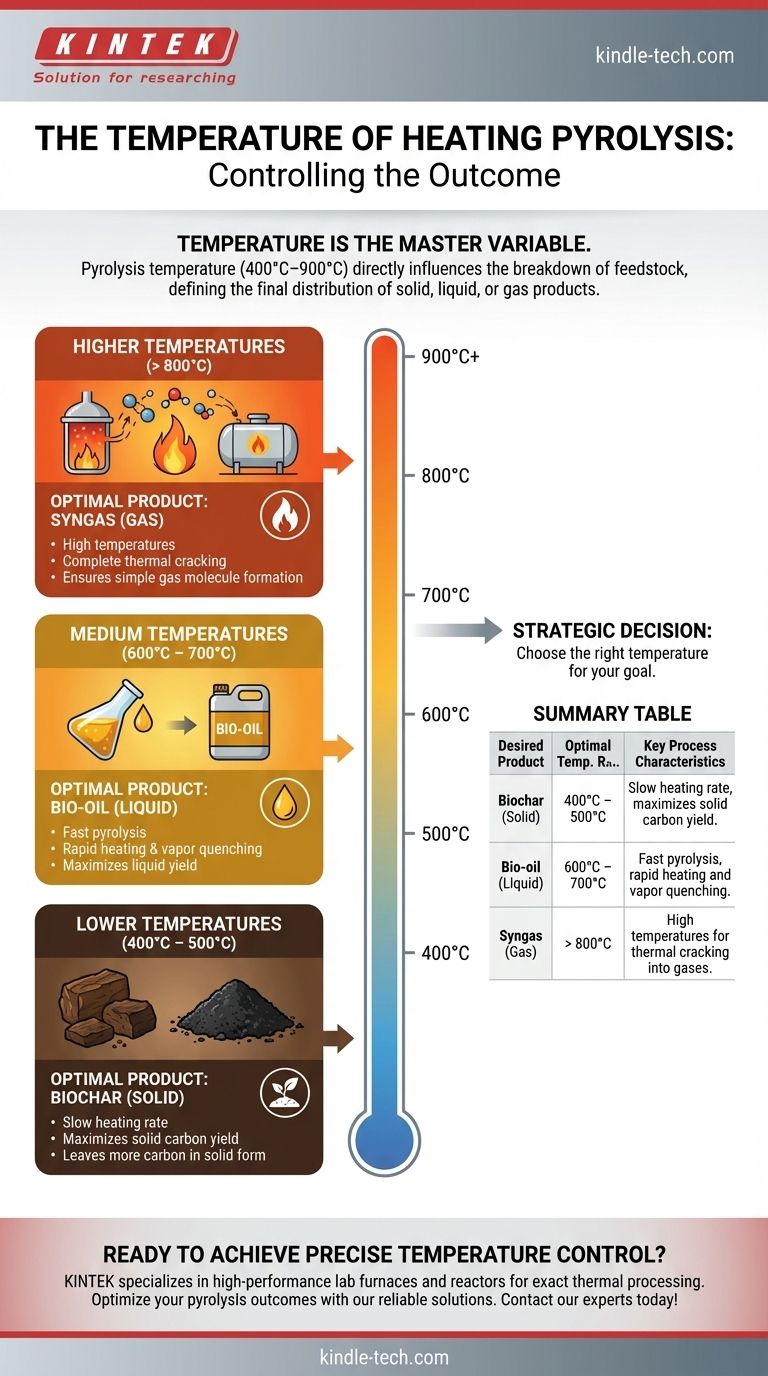

The key takeaway is that temperature is the most critical control parameter in pyrolysis. It is intentionally manipulated to determine the final distribution of products—whether you want to maximize the output of solid biochar, liquid bio-oil, or combustible gas.

Why Temperature is the Master Variable

Pyrolysis is the thermal decomposition of materials in the absence of oxygen. The temperature at which this process is conducted directly influences the rate of reaction and the chemical breakdown of the feedstock, defining the nature of the end products.

The Initial Stage: Drying and Decomposition

At lower temperatures, typically below 300°C, the primary process is the removal of moisture and the initial breakdown of less stable chemical bonds. For biomass like wood, this is where it begins to char and release water vapor and volatile organic compounds.

The Core Pyrolysis Zone: Product Formation

The most active range for pyrolysis is generally between 400°C and 700°C. In this zone, the bulk of the material decomposes into vapors, aerosols, and a solid carbon-rich residue (char). The specific temperature within this range dictates the primary output.

High-Temperature Cracking: Gas Maximization

When temperatures exceed 700°C to 900°C, the process shifts. The complex vapors and tars produced during primary pyrolysis are thermally "cracked" into smaller, lower molecular weight gaseous compounds like hydrogen, carbon monoxide, and methane.

Understanding the Temperature-Product Trade-off

Choosing a pyrolysis temperature is a strategic decision based entirely on the desired outcome. There is no single "best" temperature; there is only the right temperature for a specific goal.

Lower Temperatures for Biochar

Operating at the lower end of the pyrolysis spectrum, typically 400°C to 500°C with a slow heating rate, maximizes the yield of the solid product, biochar. The slower process leaves more carbon in its solid form.

Medium Temperatures for Bio-oil

To maximize the yield of liquid bio-oil, a "fast pyrolysis" process is often used. This involves rapidly heating the material to a moderate temperature, generally between 600°C and 700°C, and then quickly cooling the resulting vapors to condense them into liquid.

Higher Temperatures for Syngas

If the primary goal is to produce a combustible fuel gas (syngas), higher temperatures of 800°C or more are required. This ensures the complete thermal cracking of heavier hydrocarbons into simple gas molecules.

Making the Right Choice for Your Goal

Your target temperature is fundamentally linked to your desired product.

- If your primary focus is producing biochar for soil amendment or carbon sequestration: Operate at lower temperatures (400-500°C) with slower heating rates.

- If your primary focus is generating bio-oil as a liquid fuel or chemical feedstock: Utilize fast pyrolysis in a medium temperature range (600-700°C).

- If your primary focus is creating syngas for fuel or power generation: Employ high temperatures (above 800°C) to maximize the conversion of feedstock into gas.

Ultimately, controlling the temperature is how you control the outcome of the entire pyrolysis process.

Summary Table:

| Desired Product | Optimal Temperature Range | Key Process Characteristics |

|---|---|---|

| Biochar (Solid) | 400°C - 500°C | Slow heating rate, maximizes solid carbon yield. |

| Bio-oil (Liquid) | 600°C - 700°C | Fast pyrolysis, rapid heating and vapor quenching. |

| Syngas (Gas) | > 800°C | High temperatures for thermal cracking into gases. |

Ready to achieve precise temperature control for your pyrolysis process?

At KINTEK, we specialize in high-performance lab equipment, including furnaces and reactors designed for exact thermal processing. Whether your goal is to maximize biochar, bio-oil, or syngas production, our solutions deliver the reliability and precision you need.

Let's optimize your pyrolysis outcomes together. Contact our experts today to discuss your specific application and requirements!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the ceramic tube high temperature? From 1100°C to 1800°C, Choose the Right Material

- Why is a high-purity alumina lining required for high-temperature tube furnaces? Ensure Accurate Biomass Research

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere

- Why is an Alumina Ceramic Tube Support Necessary for 1100°C Experiments? Ensure Data Accuracy and Chemical Inertness

- What is the role of corundum tubes in oxygen permeation testing? Ensure Integrity for Bi-doped Membranes