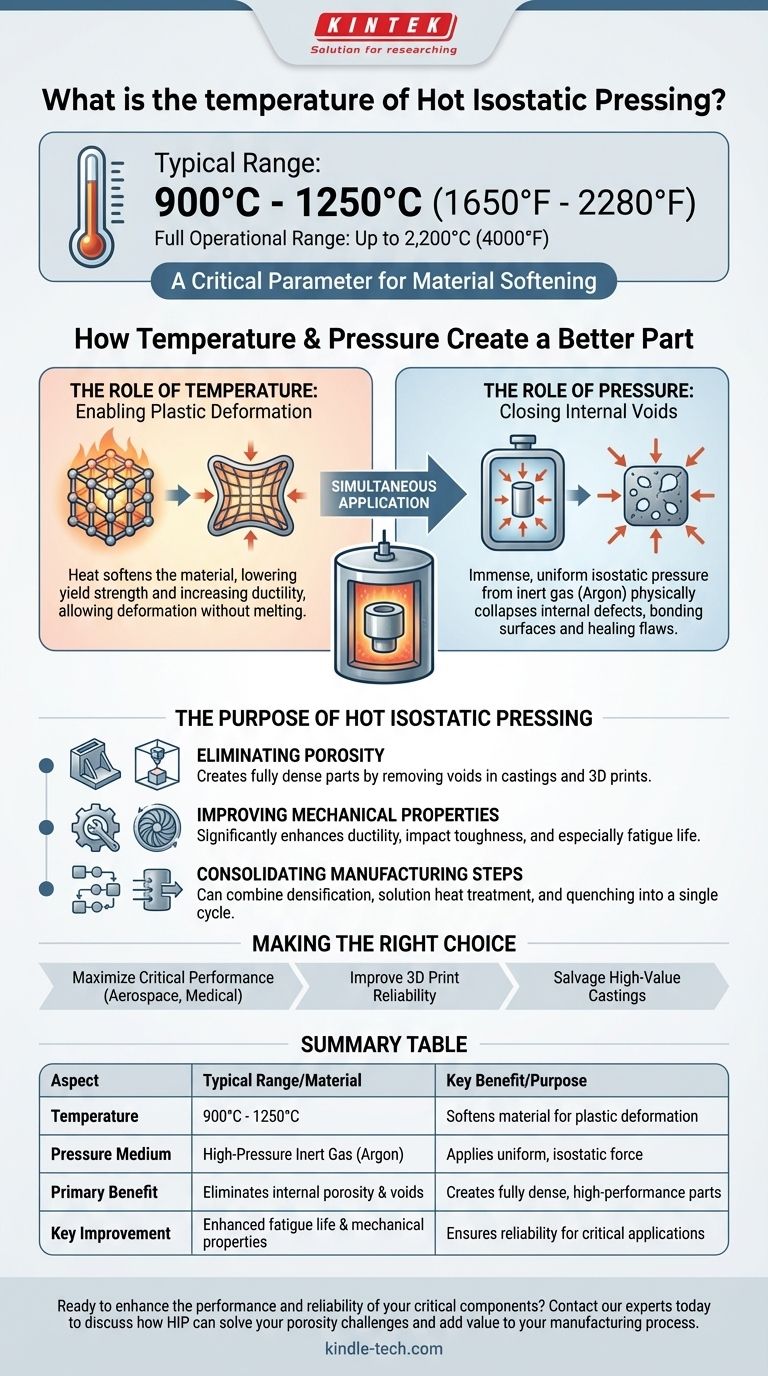

The temperature of Hot Isostatic Pressing (HIP) typically ranges from 900°C to 1250°C (1650°F to 2280°F) for most metals and alloys, but the full operational range is much wider. Depending on the specific material being processed, temperatures can be as low as a few hundred degrees Celsius or as high as 2,200°C (4000°F). The exact temperature is a critical parameter determined by the material's properties and the desired outcome.

While the question is about temperature, the core principle of HIP is the precise and simultaneous application of high temperature and uniform, isostatic pressure. Heat softens the material, while pressure provides the force to eliminate internal defects, creating a fully dense and structurally sound component.

How Temperature and Pressure Create a Better Part

Hot Isostatic Pressing is not simply a heat treatment. It is a thermomechanical process that fundamentally changes a material's internal structure by healing defects at a microscopic level.

The Role of Temperature: Enabling Plastic Deformation

The primary function of heat in the HIP process is to lower the material's yield strength and increase its ductility.

As the material heats up, it becomes soft and more plastic, allowing it to deform and flow under pressure without melting. This plasticity is what enables internal voids and pores to be closed.

The Role of Pressure: Closing Internal Voids

While the material is in its softened state, high-pressure inert gas—almost always Argon—is applied uniformly from all directions. This is what "isostatic" means.

This immense, uniform pressure physically collapses internal defects like gas porosity, shrinkage voids, and the microscopic gaps between powder particles or 3D printed layers. The contact surfaces then metallurgically bond, permanently healing the defect.

The Process Cycle: A Controlled Environment

The entire HIP cycle is meticulously controlled inside a specialized pressure vessel. Parts are loaded, the vessel is sealed, and inert gas is introduced.

The system then simultaneously ramps up temperature and pressure to the specified setpoints, holds them for a predetermined time to ensure complete densification, and finally executes a controlled cooling and depressurization phase.

The Purpose of Hot Isostatic Pressing

Engineers and manufacturers use HIP not just to fix problems, but to achieve material properties that are otherwise unattainable. It is a value-adding step for critical applications.

Eliminating Porosity in Castings and 3D Prints

For components made through casting or additive manufacturing (3D printing), porosity is an inherent risk. These microscopic voids act as stress concentrators and crack initiation sites.

HIP effectively eliminates this porosity, creating a fully dense part with a uniform microstructure. This dramatically improves reliability and performance.

Improving Mechanical Properties

By removing internal defects, HIP significantly enhances a part's mechanical properties.

This includes improved ductility, impact toughness, and especially fatigue life. For components subjected to cyclic loading, like an aircraft engine turbine disk, this improvement is not just beneficial—it's essential for safety.

Consolidating Manufacturing Steps

Modern HIP systems can combine multiple processes into a single cycle.

A part can be densified, solution heat treated, and rapidly cooled (quenched) all within the HIP vessel. This consolidation saves significant time, energy, and handling, reducing overall production costs.

Understanding the Trade-offs

While powerful, HIP is a specialized process with specific considerations. It is not a universal solution for all manufacturing challenges.

High Cost and Complexity

HIP systems represent a significant capital investment. They are complex machines that require specialized infrastructure, trained operators, and rigorous safety protocols, making the process more expensive than standard heat treatments.

Process Time and Throughput

A complete HIP cycle, including heating, soaking, and cooling, can take several hours. This makes it a batch process with lower throughput compared to continuous manufacturing methods.

Part Geometry and Preparation

The part must physically fit inside the pressure vessel. Furthermore, any internal cavities that are open to the surface must be sealed before processing. Otherwise, the high-pressure gas would enter the cavity, preventing the collapse of internal voids.

Making the Right Choice for Your Goal

Deciding whether to use HIP depends entirely on the performance requirements and value of your component.

- If your primary focus is maximizing the performance of critical components: HIP is an essential step for high-stress applications in aerospace, power generation, and medical implants where material failure is not an option.

- If your primary focus is improving the reliability of metal 3D printed parts: HIP is considered a best-practice, if not standard, post-processing step to ensure parts achieve the density and fatigue resistance of wrought materials.

- If your primary focus is salvaging high-value castings with internal defects: HIP is a highly effective method for closing shrinkage porosity and healing internal flaws, recovering complex parts that would otherwise be scrapped.

Ultimately, understanding the interplay of temperature and pressure empowers you to leverage HIP not just as a repair tool, but as a strategic process for achieving superior material properties.

Summary Table:

| Aspect | Typical Range | Key Material | Purpose |

|---|---|---|---|

| Temperature | 900°C - 1250°C (1650°F - 2280°F) | Metals & Alloys | Softens material for plastic deformation |

| Pressure Medium | High-Pressure Inert Gas (Argon) | - | Applies uniform, isostatic force |

| Primary Benefit | Eliminates internal porosity & voids | Castings, 3D Prints | Creates fully dense, high-performance parts |

| Key Improvement | Enhanced fatigue life & mechanical properties | Aerospace, Medical | Ensures reliability for critical applications |

Ready to enhance the performance and reliability of your critical components?

KINTEK specializes in advanced thermal processing solutions, including Hot Isostatic Pressing (HIP) systems and services. Our expertise in lab equipment and consumables helps you achieve superior material density, eliminate defects in castings and 3D printed parts, and significantly improve fatigue life and mechanical properties for demanding applications in aerospace, medical, and power generation.

Contact our experts today to discuss how HIP can solve your porosity challenges and add value to your manufacturing process.

Visual Guide

Related Products

- Warm Isostatic Press for Solid State Battery Research

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What are the density advantages of using vacuum hot-press equipment? Unlock 94%+ Density for Ca3Co4O9 Materials

- How does a vacuum hot press furnace achieve high densification in LLZO? Unlock Superior Ceramic Electrolyte Performance

- What are the advantages of hot press? Achieve Superior Bonding and Material Densification

- How does the vacuum environment within a hot pressing furnace protect SiCf/Ti-43Al-9V? Ensure Composite Integrity

- What is the effect of increasing the pressure during sintering? Achieve Maximum Density and Superior Performance

- What role does a vacuum hot pressing furnace play in graphite/copper composites? Master Densification & High Purity

- Why is it necessary to equip a Spark Plasma Sintering (SPS) system with a precision optical pyrometer?

- Why Use a Vacuum Hot Press for SiCp/6061 Composites? Ensure Pure Interface Bonding and Maximum Density