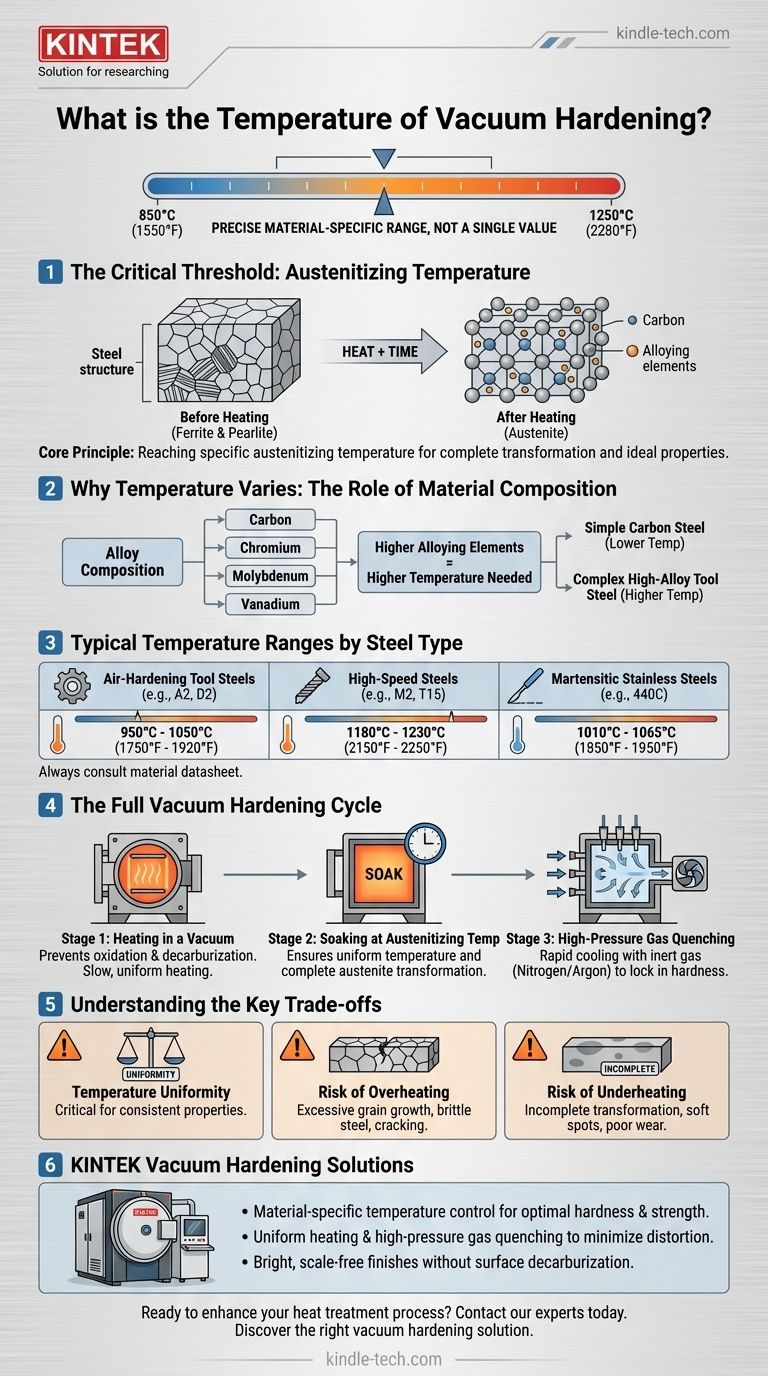

The temperature for vacuum hardening is not a single value but a precise, material-specific range. It typically falls between 850°C and 1250°C (1550°F and 2280°F), depending entirely on the chemical composition of the steel alloy being treated. The correct temperature is critical for transforming the steel's internal structure to achieve its maximum hardness and strength.

The core principle of vacuum hardening is not about hitting a generic temperature, but about reaching the specific austenitizing temperature of a particular alloy in a controlled, inert environment to achieve ideal properties without surface contamination.

Why Temperature Varies: The Role of Material Composition

The exact hardening temperature is dictated by the steel's metallurgy. The goal is to heat the material to a point where its crystalline structure transforms, a process known as austenitization.

The Critical Threshold: Austenitizing Temperature

Austenitizing is the process of heating steel to a temperature where its crystal structure changes from ferrite and pearlite to a new structure called austenite.

In this state, carbon and other alloying elements dissolve into the iron matrix, much like salt dissolving in water. This step is essential; without a complete transformation to austenite, the steel cannot be fully hardened during quenching.

How Alloying Elements Dictate Temperature

Different steel alloys contain varying amounts of elements like carbon, chromium, molybdenum, and vanadium. These elements directly influence the austenitizing temperature.

Steels with higher concentrations of these alloying elements generally require higher temperatures to fully dissolve them into the austenite structure. For example, a simple carbon steel requires a much lower temperature than a complex, high-alloy tool steel.

Typical Temperature Ranges by Steel Type

While you must always consult the material's specific datasheet, here are the general temperature ranges for common steel families:

- Air-Hardening Tool Steels (e.g., A2, D2): Typically require 950°C to 1050°C (1750°F to 1920°F).

- High-Speed Steels (e.g., M2, T15): Need significantly higher temperatures, often 1180°C to 1230°C (2150°F to 2250°F), to dissolve tough vanadium and tungsten carbides.

- Martensitic Stainless Steels (e.g., 440C): Are hardened in the range of 1010°C to 1065°C (1850°F to 1950°F).

The Full Vacuum Hardening Cycle

The hardening temperature is just one part of a multi-stage process. Understanding the full cycle provides critical context.

Stage 1: Heating in a Vacuum

The furnace chamber is pumped down to a near-perfect vacuum. The material is then heated slowly and uniformly towards the target temperature. The vacuum's primary role is to prevent oxidation and decarburization (the loss of carbon from the surface), ensuring a clean, bright part finish.

Stage 2: Soaking at Austenitizing Temperature

Once at the target temperature, the material is "soaked" or held for a predetermined time. This soak period ensures that the entire part, from surface to core, reaches a uniform temperature and that the austenite transformation is complete.

Stage 3: High-Pressure Gas Quenching

After soaking, the part is rapidly cooled (quenched) to lock in the hardened structure. In a vacuum furnace, this is achieved by flooding the chamber with a high-pressure inert gas, typically nitrogen or argon. The gas is circulated by a powerful fan to cool the part rapidly and uniformly.

Understanding the Key Trade-offs

Precise temperature control is the most critical factor in successful vacuum hardening. Deviating even slightly from the specified parameters can ruin the part.

The Critical Need for Temperature Uniformity

If one section of a component is hotter than another during the soak, it will result in inconsistent material properties. This is why furnace design elements—such as fan circulation, heating element placement, and control systems—are engineered to maintain temperature uniformity to within a few degrees across the entire workload.

The Risk of Overheating

Heating a part above its specified austenitizing temperature causes excessive grain growth. Large grains make the steel brittle and prone to cracking, severely compromising its toughness and impact resistance.

The Risk of Underheating

Failing to reach the required temperature results in an incomplete transformation to austenite. This means the steel will not fully harden during the quench, leading to soft spots, poor wear resistance, and a failure to meet performance specifications.

Making the Right Choice for Your Material

Your material's datasheet is the ultimate source of truth. However, these guidelines will help you set expectations for the vacuum hardening process.

- If your primary focus is hardening common tool steels (e.g., A2, D2): Expect a process temperature near 1000°C (1832°F) and rely on the heat treater's expertise to follow the datasheet precisely.

- If your primary focus is on high-performance, high-speed steels (e.g., M2): Be prepared for a much higher temperature cycle above 1200°C (2192°F) to achieve the necessary performance.

- If your primary focus is a bright, scale-free finish with minimal distortion: Vacuum hardening is the superior choice, as its precise temperature control and gas quenching process minimize the risks associated with older methods.

Always defer to the material manufacturer's specifications to ensure the final product meets its intended engineering requirements.

Summary Table:

| Steel Type | Typical Hardening Temperature Range | Common Examples |

|---|---|---|

| Air-Hardening Tool Steels | 950°C - 1050°C (1750°F - 1920°F) | A2, D2 |

| High-Speed Steels | 1180°C - 1230°C (2150°F - 2250°F) | M2, T15 |

| Martensitic Stainless Steels | 1010°C - 1065°C (1850°F - 1950°F) | 440C |

Achieve precise, contamination-free hardening with KINTEK's vacuum furnaces.

As specialists in lab equipment and consumables, KINTEK provides vacuum hardening solutions that deliver:

- Material-specific temperature control for optimal hardness and strength

- Uniform heating and high-pressure gas quenching to minimize distortion

- Bright, scale-free finishes without surface decarburization

Whether you're working with tool steels, high-speed steels, or stainless steels, our equipment ensures you hit the exact austenitizing temperature your alloy requires.

Ready to enhance your heat treatment process? Contact our experts today to discuss your specific laboratory needs and discover the right vacuum hardening solution for you.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vertical Laboratory Tube Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- How hot can a lab furnace get? Match the Right Heating Technology to Your Application

- What role does a high-temperature vacuum furnace play in the post-processing of Yttrium-modified Inconel 718 components?

- What is the heating mechanism of a microwave sintering furnace? Revolutionize h-BN/ZrO2/SiC Ceramic Preparation

- What is the purpose of using a precision furnace for glass stress relief? Ensure Durability in Molded Glass

- How do industrial-grade pyrolysis reactors optimize directional synthesis? Master Biomass Conversion Efficiency

- What are the 4 heating techniques used for brazing? Find Your Ideal Method for Stronger Joints

- Why is a vacuum drying oven required for the surface modification of aramid fibers? Eliminate Voids & Boost Adhesion.

- What is the process of sintering in the iron and steel industry? A Key Step for Efficient Blast Furnace Operation