In brazing, the correct temperature is the single most critical factor that defines the success of the entire process. By international definition, brazing takes place at any temperature above 840°F (450°C), but crucially, it must always remain below the melting point of the base metals being joined. There is no single universal brazing temperature; it is entirely dictated by the specific filler metal you are using.

The core principle of brazing is not about a generic temperature range, but about reaching a specific temperature above the melting point of your chosen filler alloy. This ensures the filler becomes fluid enough for capillary action while the base metals remain solid, creating a strong, metallurgically bonded joint.

Why Temperature Defines the Brazing Process

The specific temperature range is what fundamentally distinguishes brazing from other joining methods like soldering and welding. Understanding this distinction is key to producing reliable results.

The 840°F (450°C) Threshold

The 840°F (450°C) mark is the globally accepted dividing line between soldering and brazing. Any process using a filler metal that melts below this temperature is considered soldering, while any process above it is brazing.

The Role of the Filler Metal

The exact temperature for a specific brazing job is determined by the filler metal, also known as the brazing alloy. Every filler alloy has a solidus temperature (where it begins to melt) and a liquidus temperature (where it becomes fully liquid).

Your target brazing temperature must be set slightly above the filler metal's liquidus temperature to ensure it flows readily.

Staying Below the Base Metal's Melting Point

This is the absolute upper limit for the process. If the temperature reaches the melting point of the base metals, you are no longer brazing—you are welding. The goal of brazing is to join the parts without melting them, which preserves their original shape and metallurgical properties.

Enabling Capillary Action

Heating the assembly to the correct temperature allows the molten filler metal to become extremely fluid. This fluidity enables capillary action, the force that draws the filler metal into the tight gap between the two base metal parts, ensuring a complete and uniform joint.

Understanding the Trade-offs and Risks

Simply reaching a high temperature is not enough. The precision of your temperature control directly impacts the quality and integrity of the final joint.

What Happens if the Temperature is Too Low?

If the assembly does not reach the filler metal's proper flow point, the alloy will not melt completely or "wet" the surfaces of the base metals. This results in poor flow, voids, and ultimately, a weak or failed joint.

What Happens if the Temperature is Too High?

Excessive heat can be just as damaging as too little. Overheating can cause the base metals to warp, sag, or lose their desired mechanical properties. It can also damage the filler metal itself by causing certain elements to vaporize, changing its composition and weakening the joint.

The Impact of Dwell Time

Temperature is linked to time. Dwell time is the duration the assembly is held at the target brazing temperature. Holding it too long, even at the right temperature, can cause the filler metal to erode the base metal or create brittle intermetallic compounds, which can compromise the joint's strength.

Selecting the Correct Brazing Temperature

Choosing the right temperature always begins with selecting the right filler metal for your application. The filler's properties will then dictate the precise heat you need to apply.

- If your primary focus is joining common materials like copper or steel: Start by consulting the technical data sheet for a common filler metal (like a silver or copper-phosphorus alloy) to find its recommended temperature range.

- If your primary focus is joining thin or heat-sensitive components: Select a lower-temperature silver-based filler alloy to minimize the risk of distorting or damaging the base metals.

- If your primary focus is creating a joint for high-stress or high-temperature service: You will likely need a high-temperature filler, such as a nickel-based alloy, which requires more precise furnace controls to execute correctly.

Mastering temperature control is the essential skill for creating consistently strong and reliable brazed joints.

Summary Table:

| Brazing Temperature Factor | Key Information |

|---|---|

| Minimum Temperature | Above 840°F (450°C) |

| Maximum Limit | Below base metal melting point |

| Target Temperature | Above filler metal's liquidus point |

| Critical Process | Capillary action for joint formation |

| Primary Risk | Base metal damage from overheating |

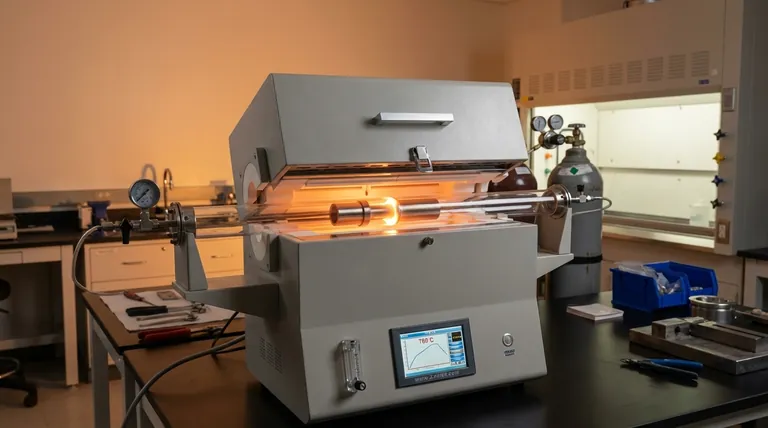

Achieve Perfect Brazing Results with KINTEK's Precision Equipment

Struggling with temperature control in your brazing process? KINTEK specializes in laboratory furnaces and thermal processing equipment that deliver the precise, consistent heat required for flawless brazed joints. Our solutions help you:

- Maintain exact temperatures within ±1°C for repeatable results

- Prevent base metal damage with sophisticated temperature profiling

- Optimize dwell times to avoid joint weakening

- Handle everything from delicate components to high-temperature alloys

Whether you're working with copper, steel, or specialized metals, KINTEK has the equipment and expertise to elevate your brazing quality.

Contact our thermal experts today to discuss how we can optimize your brazing process for stronger, more reliable joints.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Heat Treat Sintering Brazing Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- How does a quartz tube vacuum furnace contribute to the crystallization process of Ag-doped Li-argyrodite electrolytes?