In the context of producing pyrolysis oil, the process is typically conducted within a temperature range of 400°C to 900°C (750°F to 1650°F). The specific temperature chosen within this window depends heavily on the feedstock material and the desired yield of liquid, solid, or gas products.

The core principle to understand is that temperature is not a static setting, but the primary control lever in pyrolysis. Changing the temperature directly alters the chemical reactions, determining whether you primarily produce solid biochar, liquid bio-oil, or combustible gas.

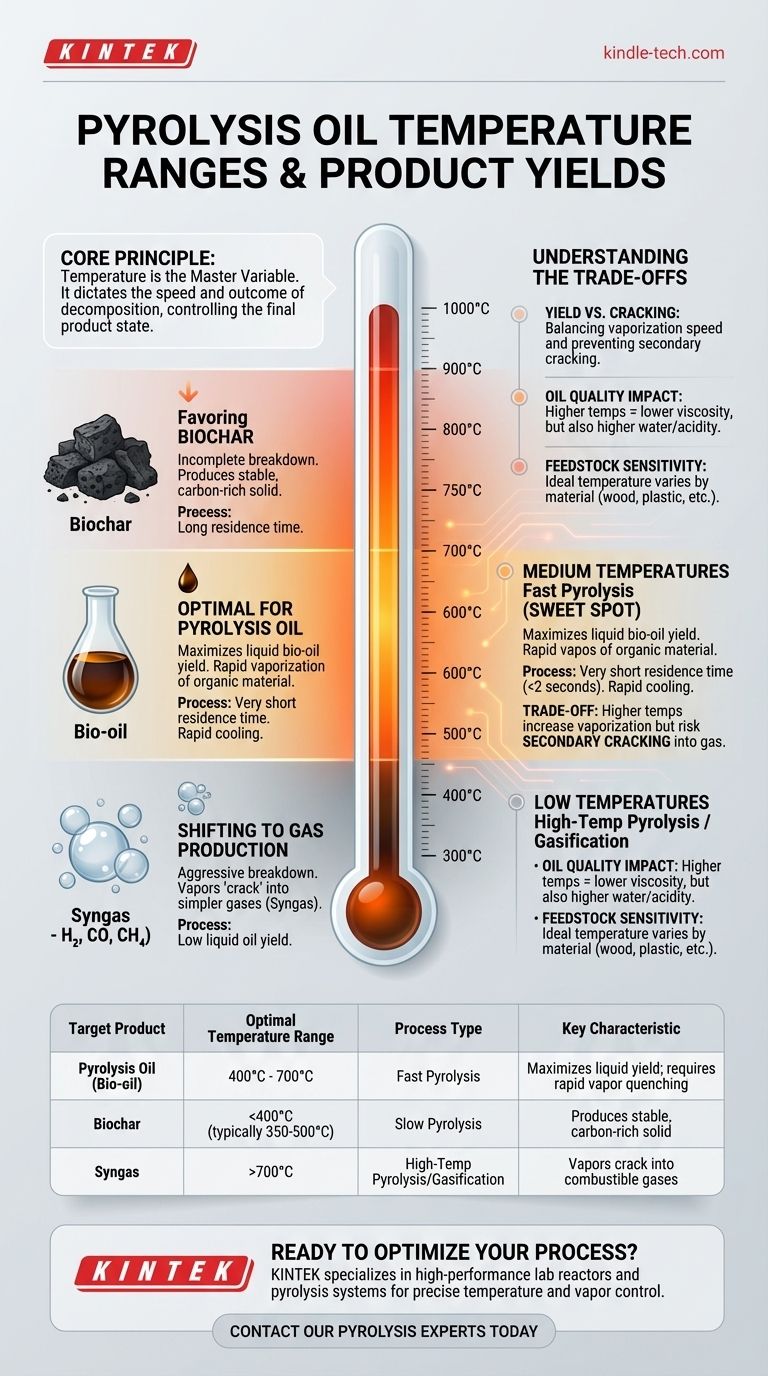

Why Temperature is the Master Variable

Pyrolysis is the thermal decomposition of materials in the absence of oxygen. Temperature dictates the speed and outcome of this decomposition, breaking down complex organic matter into simpler molecules. The final state of these molecules—solid, liquid, or gas—is a direct function of the heat applied.

Low Temperatures (< 400°C): Favoring Biochar

At lower temperatures, typically below 400°C, the process is known as slow pyrolysis or torrefaction. The breakdown of the feedstock is incomplete.

This environment favors the production of biochar, a stable, carbon-rich solid. Volatiles are driven off, but the energy is insufficient to break them down further into the complex liquid hydrocarbons that form bio-oil.

Medium Temperatures (400-700°C): The Sweet Spot for Oil

This range is the optimal zone for fast pyrolysis, where the primary goal is maximizing liquid bio-oil yield. The heat is intense enough to rapidly vaporize the organic material.

These hot vapors are then cooled and condensed quickly to capture them as a liquid—the pyrolysis oil. The key is to keep the vapors in the hot reactor for a very short time (typically less than 2 seconds) to prevent them from breaking down further.

High Temperatures (> 700°C): Shifting to Gas Production

Once temperatures exceed 700-750°C, you enter the realm of high-temperature pyrolysis or gasification. At this point, the process becomes too aggressive for oil production.

The desirable, long-chain hydrocarbon vapors that would form oil are "cracked" into much simpler, lighter gas molecules like hydrogen, carbon monoxide, and methane. This mixture, known as syngas, is valuable for energy generation but results in a significantly lower liquid oil yield.

Understanding the Trade-offs

Selecting a temperature is a strategic decision that involves balancing competing factors. There is no single "best" temperature, only the best temperature for a specific goal.

The Yield vs. Cracking Dilemma

Even within the optimal 400-700°C range, a critical balance exists. A slightly higher temperature might increase the speed of vaporization but also increases the risk of secondary cracking, where oil vapors break down into less valuable gas. This is the central challenge in optimizing bio-oil production.

The Impact on Oil Quality

Temperature doesn't just affect the quantity of oil; it affects its quality. Higher-temperature pyrolysis can produce a less viscous, lower-molecular-weight oil.

However, this often comes at the cost of increased water content and acidity (lower pH), which can make the oil more corrosive and difficult to upgrade into a finished fuel.

Feedstock and Process Sensitivity

Different feedstocks (e.g., wood, plastics, tires) decompose at different rates and temperatures. The ideal temperature for pyrolyzing hardwood will be different from that for waste plastic. The efficiency of the reactor and the speed at which vapors are removed and cooled are just as critical as the temperature itself.

Optimizing Temperature for Your Objective

To apply this knowledge effectively, you must first define your primary output. The ideal temperature is a direct consequence of that goal.

- If your primary focus is maximizing liquid bio-oil yield: Operate a fast pyrolysis process within the 450°C to 650°C range, ensuring rapid vapor cooling to prevent secondary cracking.

- If your primary focus is producing high-quality biochar: Use a slow pyrolysis process at lower temperatures, generally between 350°C and 500°C, with a longer residence time.

- If your primary focus is generating syngas for energy: Run the process at high temperatures, typically above 750°C, to intentionally promote the cracking of vapors into non-condensable gases.

Ultimately, mastering pyrolysis is about precisely manipulating temperature and time to dictate the final product distribution.

Summary Table:

| Target Product | Optimal Temperature Range | Process Type | Key Characteristic |

|---|---|---|---|

| Pyrolysis Oil (Bio-oil) | 400°C - 700°C | Fast Pyrolysis | Maximizes liquid yield; requires rapid vapor quenching |

| Biochar | < 400°C (typically 350°C - 500°C) | Slow Pyrolysis | Produces stable, carbon-rich solid |

| Syngas | > 700°C | High-Temp Pyrolysis/Gasification | Vapors crack into combustible gases (H2, CO, CH4) |

Ready to optimize your pyrolysis process and achieve your target product yields?

KINTEK specializes in high-performance lab reactors and pyrolysis systems designed for precise temperature control and efficient vapor management. Whether your goal is to maximize bio-oil, produce high-quality biochar, or generate syngas, our equipment is engineered to deliver reliable and repeatable results.

Contact our pyrolysis experts today to discuss your specific feedstock and objectives. Let us help you select the ideal system to enhance your research and production efficiency.

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

People Also Ask

- How does thermal treatment equipment enhance biosynthesized ferrihydrite? Unlock High-Performance MRI Contrast Agents

- What is the process of electron beam coating? A High-Purity Thin Film Deposition Guide

- What requires a medium for heat transfer? Conduction and Convection Explained

- What is the use of sputter coating? Achieve Superior Thin-Film Deposition for Your Lab

- What is the flash sintering process? Revolutionize Your Materials Processing in Seconds

- How accurate are diamond testers? A Guide to Their True Capabilities and Limits

- What is the importance of a laboratory electric constant temperature drying oven? Ensure Accurate Biomass Analysis

- What is the best material for end mills? A Guide to Hardness vs. Toughness for Your Application