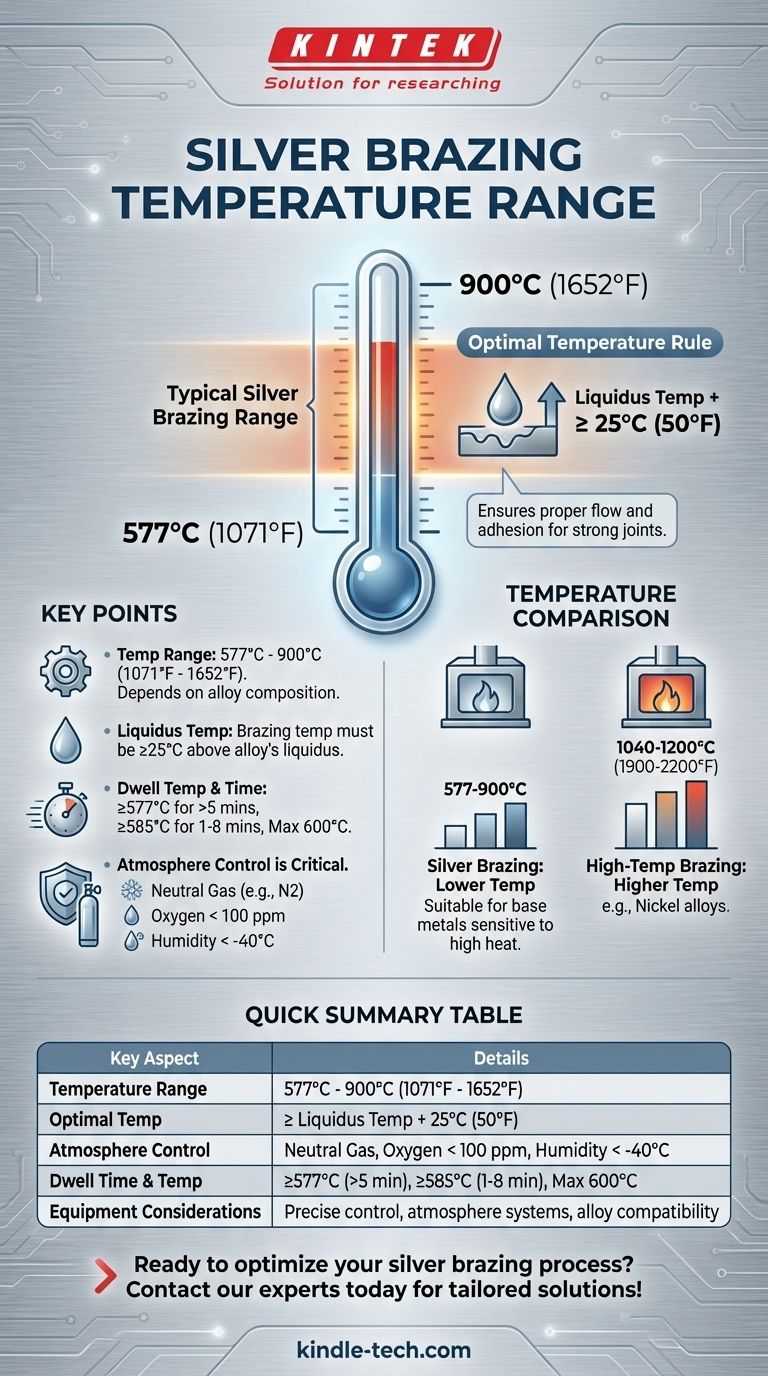

Silver brazing, a process used to join metals, involves heating a filler metal (silver-based alloy) to a temperature above its melting point but below the melting point of the base metals being joined. The temperature range for silver brazing typically depends on the specific alloy used, but it generally falls between 577°C (1071°F) and 900°C (1652°F). The optimal temperature is usually at least 25°C (50°F) above the liquidus temperature of the braze alloy to ensure proper flow and adhesion. Key factors influencing the temperature range include the alloy composition, the base metals being joined, and the desired joint strength. Proper atmosphere control, such as maintaining a neutral gas environment with low oxygen and humidity, is also critical for successful brazing.

Key Points Explained:

-

Temperature Range for Silver Brazing:

- Silver brazing typically occurs within a temperature range of 577°C (1071°F) to 900°C (1652°F). This range ensures the filler metal melts and flows properly without damaging the base metals.

- The exact temperature depends on the specific silver alloy used, as different alloys have varying melting points.

-

Importance of Liquidus Temperature:

- The brazing temperature should be at least 25°C (50°F) above the liquidus temperature of the braze alloy. The liquidus temperature is the point at which the alloy becomes fully liquid.

- Staying above this temperature ensures the filler metal flows adequately to form strong, durable joints.

-

Optimal Temperature Selection:

- The lowest possible temperature within the recommended range is preferred to minimize thermal stress on the base metals and reduce energy consumption.

- For example, if the liquidus temperature of a silver alloy is 600°C (1112°F), the brazing temperature should be at least 625°C (1157°F).

-

Atmosphere Control:

- A controlled atmosphere is critical for successful brazing. The environment should be free of oxidants, oxygen, and moisture.

- Ideal conditions include:

- Neutral gas (e.g., pure nitrogen).

- Oxygen content < 100 ppm.

- Humidity < -40°C.

- This prevents oxidation and ensures proper wetting of the filler metal.

-

Dwell Temperature and Time:

- The dwell temperature (the temperature maintained during brazing) and the duration are critical parameters.

- For silver brazing, typical parameters include:

- ≥577°C (1071°F) for more than 5 minutes.

- ≥585°C (1085°F) for 1 to 8 minutes.

- A maximum temperature of 600°C (1112°F) to avoid overheating.

-

Comparison with High-Temperature Brazing:

- Silver brazing operates at lower temperatures compared to high-temperature brazing of materials like nickel alloys, which occurs at 1040-1200°C (1900-2200°F).

- This makes silver brazing suitable for joining materials that cannot withstand extremely high temperatures.

-

Practical Considerations for Equipment Purchasers:

- When selecting brazing equipment, ensure it can maintain precise temperature control within the required range.

- Consider the need for atmosphere control systems, such as vacuum furnaces or inert gas environments, to achieve optimal brazing conditions.

- Evaluate the compatibility of the equipment with the specific silver alloys and base metals being used.

By understanding these key points, equipment and consumable purchasers can make informed decisions about the materials and tools needed for successful silver brazing operations.

Summary Table:

| Key Aspect | Details |

|---|---|

| Temperature Range | 577°C (1071°F) to 900°C (1652°F) |

| Liquidus Temperature | Brazing temp ≥ 25°C (50°F) above liquidus temp for proper flow |

| Atmosphere Control | Neutral gas, oxygen < 100 ppm, humidity < -40°C |

| Dwell Temperature & Time | ≥577°C (1071°F) for >5 mins, ≥585°C (1085°F) for 1-8 mins, max 600°C (1112°F) |

| Equipment Considerations | Precise temp control, atmosphere systems, alloy/base metal compatibility |

Ready to optimize your silver brazing process? Contact our experts today for tailored solutions!

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- Why is a high-purity hydrogen atmosphere furnace required for W-TiC pre-sintering? Achieve Pure Material Densification

- Does carburization increase hardness? Achieve Superior Wear Resistance for Critical Components

- What is an exothermic atmosphere in a furnace? A Guide to Cost-Effective Metal Protection

- What is an exothermic atmosphere? A Guide to Cost-Effective, Self-Sustaining Heat Treatment Gases

- What role do high-vacuum or atmosphere furnaces play in the annealing of metals? Enhance Material Performance & Purity

- Which atmosphere is requisite for the sintering process? A Guide to Optimizing Your Material's Properties

- What is the purpose of pre-treating coal samples? Ensure Accurate Pyrolysis with Nitrogen Drying

- What is the role of a program-controlled carbonization furnace in the preparation of lignin-based carbon fiber? Explained