In soil science, a muffle furnace is a high-temperature oven used for three primary analytical tasks: determining soil organic matter content, analyzing specific types of water content, and preparing samples for trace metal analysis. It functions by heating soil samples to extreme temperatures in a controlled, contamination-free environment, allowing scientists to measure changes in the soil's mass and composition.

A muffle furnace's core value is its ability to use extreme, indirect heat to burn away or isolate specific components of a soil sample. By precisely controlling this combustion, it allows for accurate measurement of what remains, providing critical data on soil health and composition.

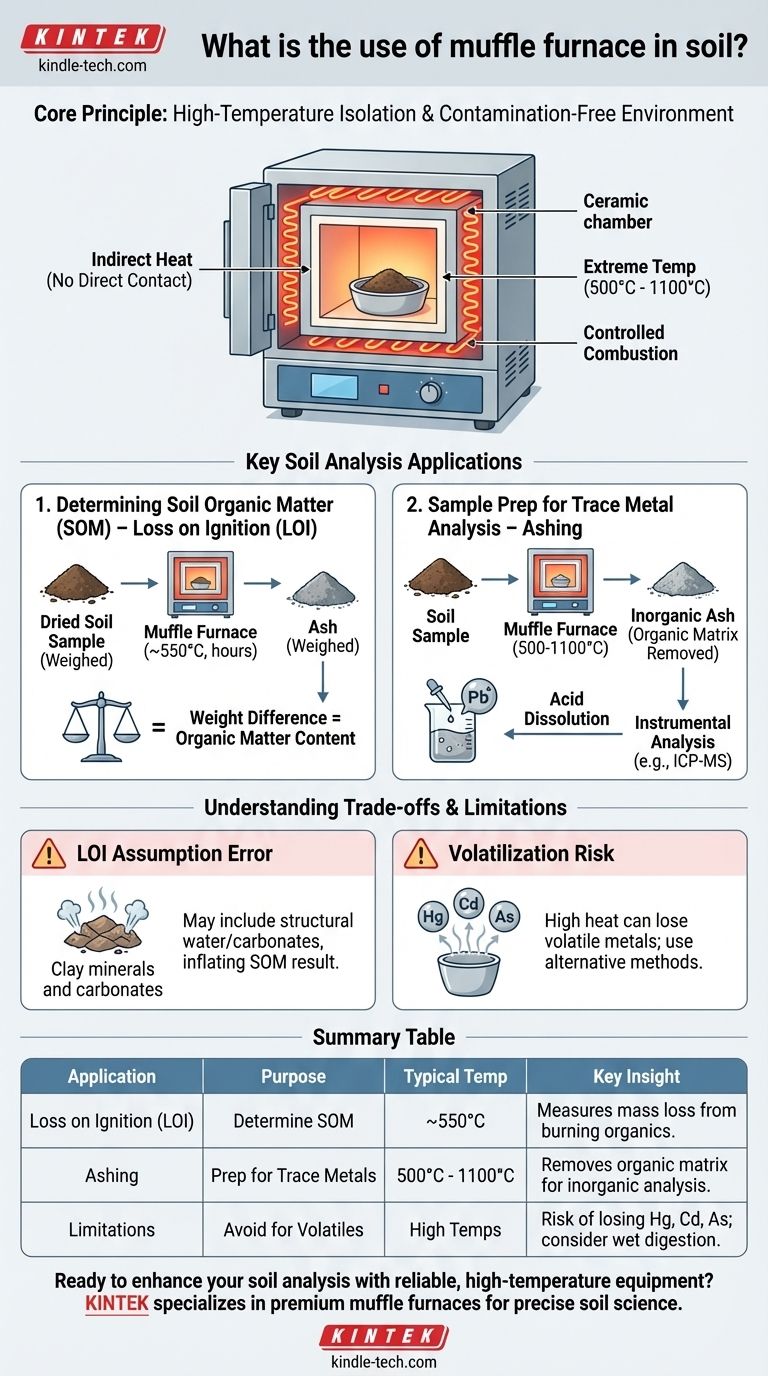

The Core Principle: High-Temperature Isolation

A muffle furnace is more than just a powerful oven. Its design is central to its scientific utility.

How a Muffle Furnace Works

The key is in the name "muffle." The furnace's heating elements are physically separated from the internal chamber where the sample is placed.

This design prevents direct contact between the heating source and the sample, which is crucial for reducing the risk of cross-contamination. The chamber is heated evenly and cleanly, ensuring that any change in the soil sample is due to the heat itself, not a reaction with the heating elements.

Why High Temperature is Critical

Muffle furnaces can operate at extremely high temperatures, often between 500°C and 1100°C (932°F to 2012°F).

This level of heat is necessary to induce specific chemical and physical changes, most notably the complete combustion of organic materials into carbon dioxide and ash.

Key Applications in Soil Analysis

The furnace's capabilities are leveraged for several standard soil testing procedures.

Determining Soil Organic Matter (SOM)

This is the most common use for a muffle furnace in soil labs. The technique is called Loss on Ignition (LOI).

First, a dried soil sample is weighed precisely. It is then placed in the muffle furnace and heated to around 550°C for several hours. This intense heat burns away virtually all the organic matter.

After cooling, the sample is weighed again. The difference in weight before and after heating represents the amount of organic matter that was present in the soil.

Sample Preparation for Trace Metal Analysis

Before soil can be analyzed for most heavy metals, the complex organic matrix must be removed.

The process, known as ashing, involves heating the soil sample in the furnace to combust all organic compounds. This leaves behind only the inorganic, mineral components of the soil, including the metals.

This ash can then be dissolved in acid and analyzed using other instruments, a process that would be much less accurate if the organic matter were still present.

Understanding the Trade-offs

While powerful, the muffle furnace technique has limitations that every analyst must understand.

The "Loss on Ignition" Assumption

The LOI method assumes that the only mass lost during heating is from organic matter. This is not always true.

Certain clay minerals lose structurally bound water at high temperatures, and carbonates can decompose. Both processes result in weight loss that can be incorrectly attributed to organic matter, potentially inflating the final result.

Volatilization of Certain Elements

The extreme heat used in ashing can cause some semi-volatile elements, such as mercury, cadmium, or arsenic, to turn into a gas and escape the sample.

For this reason, a muffle furnace is unsuitable for preparing samples when these specific elements are the target of the analysis. Alternative methods like wet digestion are required.

Making the Right Choice for Your Analysis

Use the muffle furnace when its capabilities align with your analytical goals.

- If your primary focus is estimating overall soil health and carbon content: The muffle furnace is the standard tool for the Loss on Ignition (LOI) method to determine soil organic matter.

- If your primary focus is preparing samples for most heavy metal analyses: Using a muffle furnace for ashing is a critical step to remove organic interference and concentrate your target elements.

- If your primary focus is analyzing for volatile metals or require high precision on soils with high clay content: You must consider the limitations of the furnace and may need to use alternative analytical methods.

Understanding these applications and their inherent trade-offs allows you to use the muffle furnace not just as a tool, but as a precise instrument for revealing the hidden composition of soil.

Summary Table:

| Application | Purpose | Typical Temperature | Key Insight |

|---|---|---|---|

| Loss on Ignition (LOI) | Determine Soil Organic Matter (SOM) | ~550°C | Measures mass loss after burning off organic material. |

| Ashing | Prepare samples for trace metal analysis | 500°C - 1100°C | Removes organic matrix to concentrate inorganic elements. |

| Limitations | Avoid for volatile elements (e.g., Hg, Cd) | High Temperatures | Can cause loss of volatile metals; use wet digestion instead. |

Ready to enhance your soil analysis with reliable, high-temperature equipment? KINTEK specializes in premium muffle furnaces and lab equipment designed for precise soil science applications. Whether you're measuring organic matter or preparing samples for metal analysis, our solutions ensure accuracy and contamination-free results. Contact our experts today to find the perfect furnace for your laboratory's needs!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the significance of using a high-temperature box furnace in SSRS? Streamlining BZY20 Ceramic Production

- What function does a constant temperature blast drying oven serve in the magnesite flotation test? Ensure Sample Integrity

- What role does a muffle furnace play in LAGP production? Essential Melting for High-Performance Electrolytes

- How do you ash a sample? Choose the Right Method for Accurate Inorganic Analysis

- What precautions you will take while handling the muffle furnace? Ensure Safe and Efficient Operation

- What conditions does a high-temperature box resistance furnace provide for slate ceramsite? Optimize Your Sintering Process

- How does a muffle furnace contribute to LATP ceramics post-heat treatment? Optimize Your Microstructure Repair

- Why is a muffle furnace utilized for the post-sintering annealing of LATP samples? Optimize Your SPS Materials