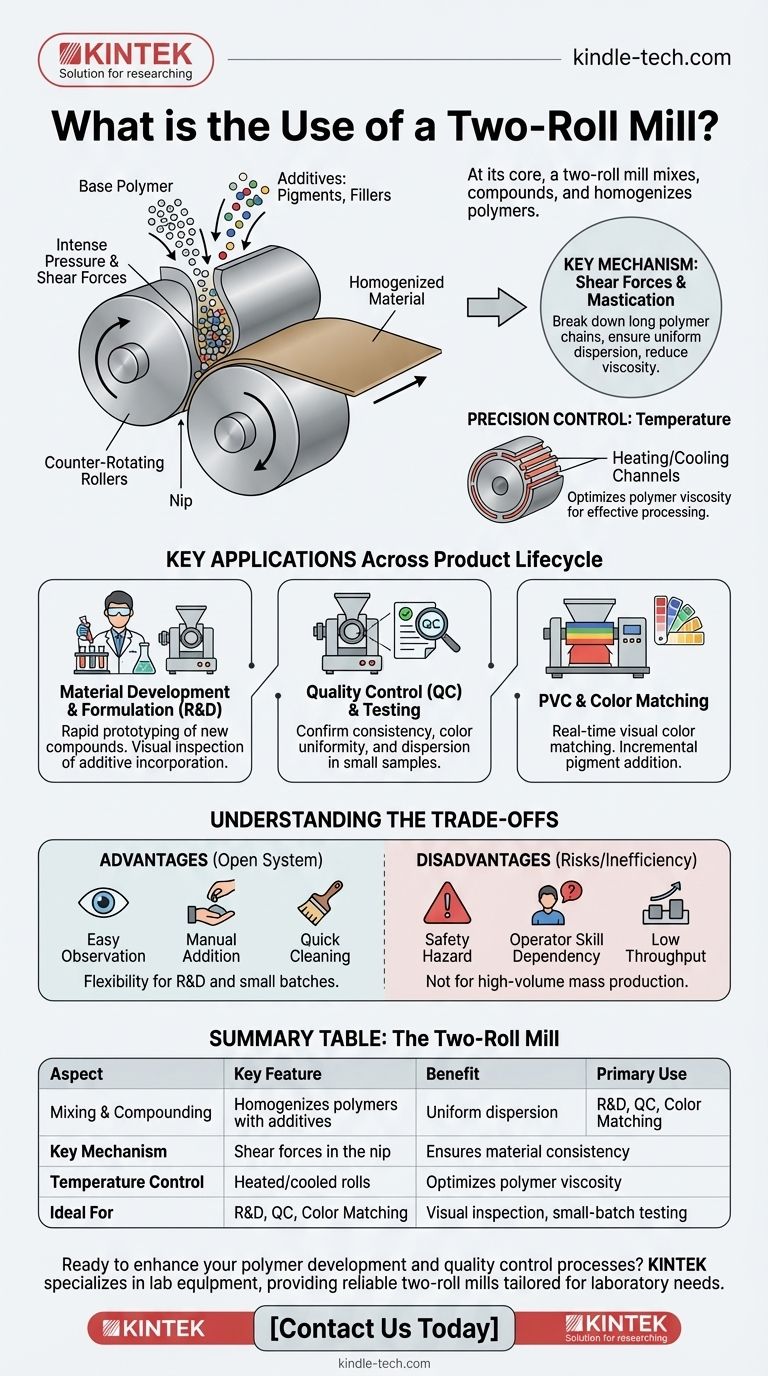

At its core, a two-roll mill is a machine used to mix, compound, and homogenize polymers. It uses two large, counter-rotating rollers to apply intense pressure and shear forces to materials like rubber and plastics. This process, known as milling, is essential for blending base polymers with additives like pigments, fillers, and chemical agents to create a uniform final material with desired properties.

A two-roll mill is more than just a mixer; it is a fundamental tool for manipulating the physical and chemical properties of polymers through controlled mechanical and thermal energy. Its primary value lies in its use for material development, quality control testing, and small-scale production where direct observation and process control are critical.

How a Two-Roll Mill Fundamentally Works

The effectiveness of a two-roll mill comes from the simple but powerful interaction between its two main components. Understanding this mechanism is key to appreciating its applications.

The Role of Shear and Mastication

A small gap, known as the nip, exists between the two counter-rotating rolls. As polymer is introduced, it is repeatedly pulled into this nip.

The intense shear forces in the nip tear the material apart, ensuring that different components, like colorants or strengthening fillers, are thoroughly dispersed.

For materials like natural rubber, this process is called mastication. The mechanical energy physically breaks down long polymer chains, reducing the material's viscosity and making it easier to process in subsequent steps.

Precision Control of Temperature

The rolls are typically equipped with internal channels for heating or cooling. Temperature control is critical because it directly influences the polymer's viscosity (its ability to flow).

By adjusting the temperature, an operator can ensure the material is soft enough to mix properly but not so fluid that it loses its structure, optimizing the compounding process.

Key Applications Across the Product Lifecycle

The versatility of the two-roll mill makes it a valuable asset in nearly every stage of polymer processing, from initial concept to final quality assurance.

Material Development and Formulation

In research and development (R&D), two-roll mills are indispensable. They allow material scientists to create and test new polymer formulations on a small scale.

Scientists can easily add precise amounts of different chemicals and visually inspect how they incorporate into the base polymer, making it a perfect tool for rapid prototyping of new compounds.

Quality Control and Testing

For manufacturing, consistency is paramount. A lab-scale two-roll mill is a standard quality control (QC) instrument.

A small sample from a large production batch can be quickly milled to verify its properties. This test can confirm color uniformity, proper dispersion of additives, and overall material behavior before the full batch is approved.

PVC and Color Matching

The open design of a two-roll mill makes it ideal for visual color matching.

Operators can add pigments incrementally and see the color develop in real-time. Once the desired shade is achieved, a small sheet can be taken directly from the mill for analysis, a common practice in the PVC industry.

Understanding the Trade-offs

While powerful, the two-roll mill is not the right tool for every job. Its design presents a specific set of advantages and disadvantages compared to other mixing technologies.

Open vs. Closed Systems

The two-roll mill is an open system. This is excellent for observation, manual addition of ingredients, and quick cleaning.

However, this openness exposes the operator to fumes and creates a significant safety hazard from the powerful rotating nip. It also introduces a higher risk of contamination from the surrounding environment compared to a closed system like an internal (Banbury) mixer.

Operator Skill Dependency

The quality of the final mix is highly dependent on the operator's skill. The operator must manually cut, fold, and guide the material back into the nip to ensure all parts of the batch are mixed uniformly.

An inexperienced operator can easily produce an inconsistent product. This contrasts with automated internal mixers that offer more repeatable, operator-independent results.

Batch Size and Throughput

Two-roll mills are fundamentally batch processors and are generally less efficient for high-volume production than alternatives.

For large-scale, continuous manufacturing, a twin-screw extruder or a large internal mixer will deliver much higher throughput and automation. The two-roll mill excels in flexibility, not mass production.

Making the Right Choice for Your Goal

Selecting the correct mixing technology depends entirely on your primary objective. The two-roll mill is a specialized tool that excels in specific scenarios.

- If your primary focus is R&D and rapid formulation testing: The two-roll mill's open design, small batch capability, and direct feedback make it the ideal choice.

- If your primary focus is high-volume production of a single formulation: An internal mixer (like a Banbury) or a continuous compounding extruder will provide far greater efficiency and automation.

- If your primary focus is quality control sampling and color matching: A lab-scale two-roll mill is the industry standard for its ability to quickly prepare testable samples and allow for visual verification.

Ultimately, the two-roll mill remains a foundational and versatile piece of equipment in the world of polymer processing.

Summary Table:

| Aspect | Key Feature | Benefit |

|---|---|---|

| Primary Use | Mixing & Compounding | Homogenizes polymers with additives like pigments and fillers |

| Key Mechanism | Shear forces in the nip gap | Ensures uniform dispersion and material consistency |

| Temperature Control | Heated/cooled rolls | Optimizes polymer viscosity for effective processing |

| Ideal For | R&D, QC, color matching | Enables visual inspection, small-batch testing, and rapid prototyping |

Ready to enhance your polymer development and quality control processes? KINTEK specializes in lab equipment and consumables, providing reliable two-roll mills tailored for laboratory needs. Whether you're in R&D, material testing, or small-scale production, our solutions deliver precise control and consistent results. Contact us today to find the perfect equipment for your polymer processing challenges!

Visual Guide

Related Products

- Open Type Two Roll Mixing Mill Machine for Rubber Crusher

- Laboratory Ball Mill Jar Mill with Metal Alloy Grinding Jar and Balls

- Laboratory Single Horizontal Jar Mill

- Laboratory Four-Body Horizontal Jar Mill

- Laboratory Grinding Mill Mortar Grinder for Sample Preparation

People Also Ask

- What is the role of high-speed melt mixing equipment? Key to RPE/CSPE Thermoplastic Elastomer Synthesis

- What are the two common types of injection molding processes? Thermoplastic vs. Thermoset Explained

- What is the injection molding process step by step? A Guide to High-Volume Manufacturing

- What are the advantages of dual extruders? Unlock Multi-Material and Soluble Support Printing

- What is the difference between single screw and twin screw? Choose the Right Extruder for Your Process

- How to make compound rubber? Master the Sequence to Prevent Scorch and Ensure Quality

- How many types of rolling mills are there? A Guide to Roll Configurations & Capabilities

- What are the advantages of twin screw extruder? Superior Mixing, Flexibility & Efficiency