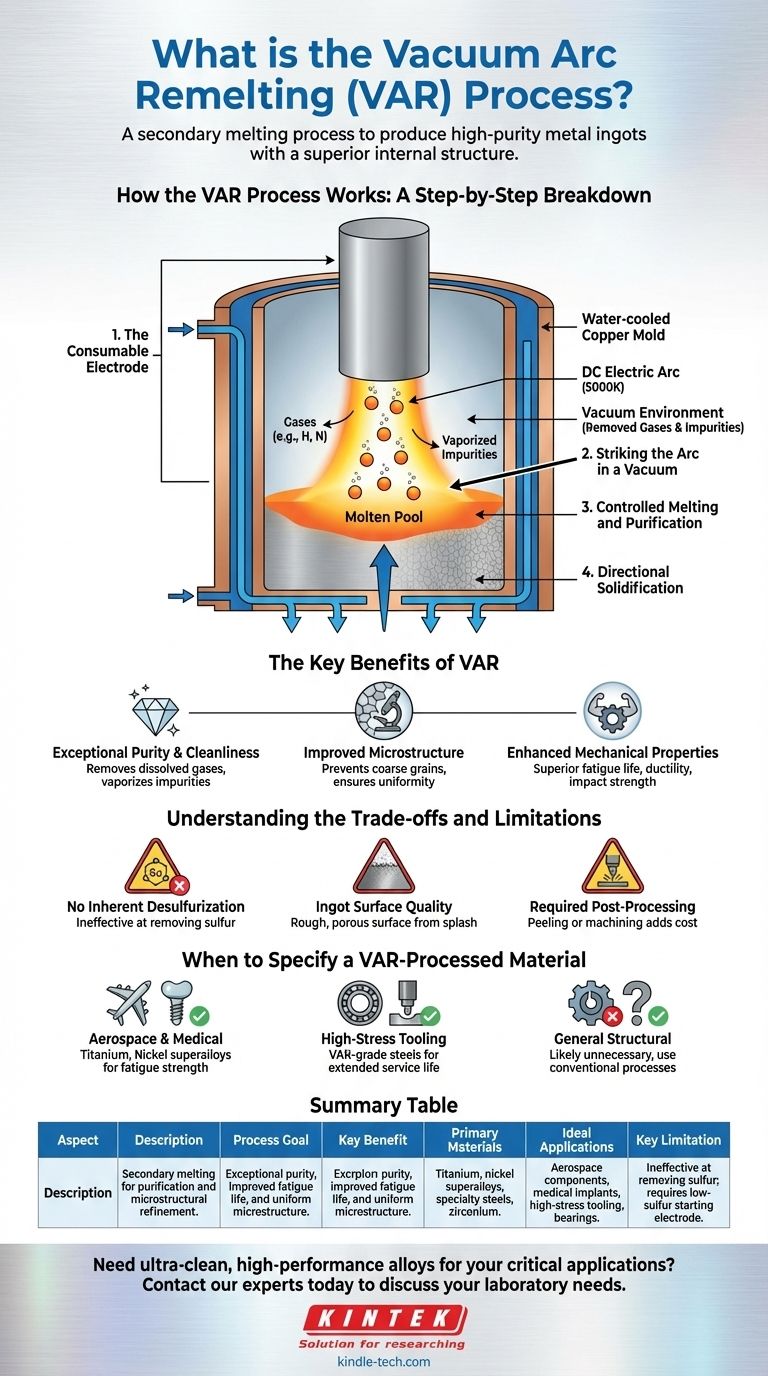

Vacuum Arc Remelting (VAR) is a secondary melting process used to produce high-purity metal ingots with a superior internal structure and enhanced mechanical properties. It functions by progressively melting a specially prepared cylindrical electrode using a high-temperature electric arc inside a vacuum. This molten metal then drips down and resolidifies in a controlled manner within a water-cooled copper mold, refining the material as it solidifies.

The core purpose of VAR is not simply to remelt a metal, but to purify it. By forcing molten droplets to pass through an intense arc within a vacuum, the process systematically removes dissolved gases and vaporizes impurities, resulting in an exceptionally clean and uniform alloy required for the most demanding applications.

How the VAR Process Works: A Step-by-Step Breakdown

The VAR process is a highly controlled sequence designed to maximize purity and metallurgical quality. Each stage plays a critical role in refining the final ingot.

The Consumable Electrode

The process begins with a solid cylinder of the metal to be refined, known as a consumable electrode. This electrode is typically formed from a primary melting process and serves as the raw material for VAR.

Striking the Arc in a Vacuum

The electrode is suspended inside a sealed, water-cooled copper mold, and the chamber is evacuated to create a high vacuum. A powerful DC electric arc is then struck between the bottom of the electrode (the cathode) and a small amount of starter material at the base of the mold (the anode).

Controlled Melting and Purification

The intense heat of the arc, reaching nearly 5000K, melts the tip of the electrode. As the metal liquefies, it forms droplets that detach and fall toward the mold below.

During their fall through the vacuum and high-temperature arc zone, the droplets undergo significant physical and chemical reactions. Dissolved gases like hydrogen and nitrogen are pulled out by the vacuum, and impurities with low boiling points are vaporized and removed.

Directional Solidification

The purified droplets collect in a molten pool at the bottom of the water-cooled mold. Because the mold is actively cooled, the metal begins to solidify progressively from the bottom up and from the outside in. This controlled solidification creates a highly uniform and refined crystal structure, minimizing chemical segregation and internal defects.

The Key Benefits of Vacuum Arc Remelting

Industries specify VAR materials when performance and reliability are paramount. The benefits directly address the typical failure points of conventionally produced metals.

Exceptional Purity and Cleanliness

The primary advantage of VAR is the production of ultra-clean alloys. The vacuum environment effectively removes dissolved gases, while the high temperature vaporizes many non-metallic inclusions and trace elemental impurities.

Improved Microstructure

The controlled, directional solidification process prevents the formation of coarse, irregular grain structures. This results in a uniform, fine-grained microstructure, which is critical for predictable material behavior under stress.

Enhanced Mechanical Properties

The combined effect of high purity and a refined microstructure leads to significant improvements in key mechanical properties. These include superior fatigue life, ductility, fracture toughness, and impact strength.

Understanding the Trade-offs and Limitations

While VAR produces superior materials, it is not a universal solution. Understanding its inherent limitations is crucial for proper application.

No Inherent Desulfurization

The VAR process is ineffective at removing sulfur. Therefore, the sulfur content of the initial consumable electrode must be very low, as it will persist in the final product.

Ingot Surface Quality

Molten metal splash during the process can lead to a rough and porous ingot surface. This surface layer often has a higher concentration of inclusions and volatile elements that have condensed on the cooler mold wall.

Required Post-Processing

Due to the poor surface quality, the resulting VAR ingot must undergo a surface peeling or machining operation before it can be subjected to hot processing like forging or rolling. This adds a necessary and costly step to the manufacturing workflow.

When to Specify a VAR-Processed Material

The decision to use a VAR material is an engineering choice driven by the demands of the final application. It is specified for components where failure is not an option.

- If your primary focus is aerospace or medical implants: Specify VAR for materials like titanium, zirconium, and nickel-based superalloys to achieve the required fatigue strength and biocompatibility.

- If your primary focus is high-stress tooling or bearings: Use VAR-grade steels (often designated with "HV") for their superior cleanliness, which directly translates to extended service life under extreme loads.

- If your primary focus is general structural or industrial fabrication: VAR is likely unnecessary overhead, and more cost-effective conventional melting processes are suitable.

Ultimately, specifying a VAR material is a strategic decision to invest in metallurgical purity for applications where performance and reliability are non-negotiable.

Summary Table:

| Aspect | Description |

|---|---|

| Process Goal | Secondary melting for purification and microstructural refinement. |

| Key Benefit | Exceptional purity, improved fatigue life, and uniform microstructure. |

| Primary Materials | Titanium, nickel superalloys, specialty steels, zirconium. |

| Ideal Applications | Aerospace components, medical implants, high-stress tooling, bearings. |

| Key Limitation | Ineffective at removing sulfur; requires low-sulfur starting electrode. |

Need ultra-clean, high-performance alloys for your critical applications?

The Vacuum Arc Remelting (VAR) process is essential for components where failure is not an option. At KINTEK, we specialize in providing the high-quality lab equipment and consumables needed to support advanced metallurgical processes like VAR. Whether you are in aerospace, medical implant manufacturing, or producing high-stress tooling, our solutions help ensure material integrity and performance.

Let us help you achieve the superior material properties your projects demand. Contact our experts today to discuss your specific laboratory needs.

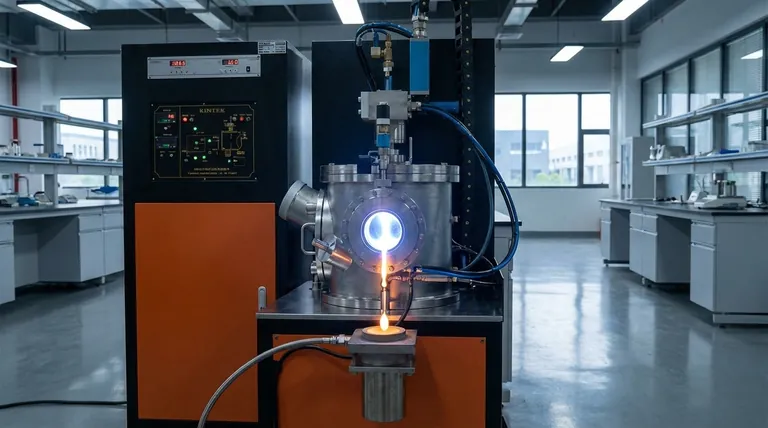

Visual Guide

Related Products

- Vacuum Arc Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

People Also Ask

- What is a remelting process? A Guide to High-Purity Metal Refinement

- What is the overview of vacuum arc remelting? Achieve Ultra-Clean, High-Performance Alloys

- What is the remelting process? Achieve Ultimate Purity and Performance for High-Strength Alloys

- How does vacuum arc remelting work? Achieve Ultra-Clean, High-Performance Metal Alloys

- What is VAR in metallurgy? Achieve Superior Metal Purity and Performance