Vacuum Arc Remelting (VAR) is a secondary metallurgical process used to produce steel and special alloys with exceptionally high levels of purity and structural integrity. It involves remelting a previously cast steel bar, called an electrode, under a high vacuum using an electric arc. This controlled remelting purifies the metal and refines its internal structure, resulting in a final ingot with superior mechanical properties.

The core purpose of VAR is not to make steel, but to refine it. By remelting the metal in a vacuum, the process removes dissolved gases and other impurities while precisely controlling solidification to create a dense, uniform, and defect-free material for mission-critical applications.

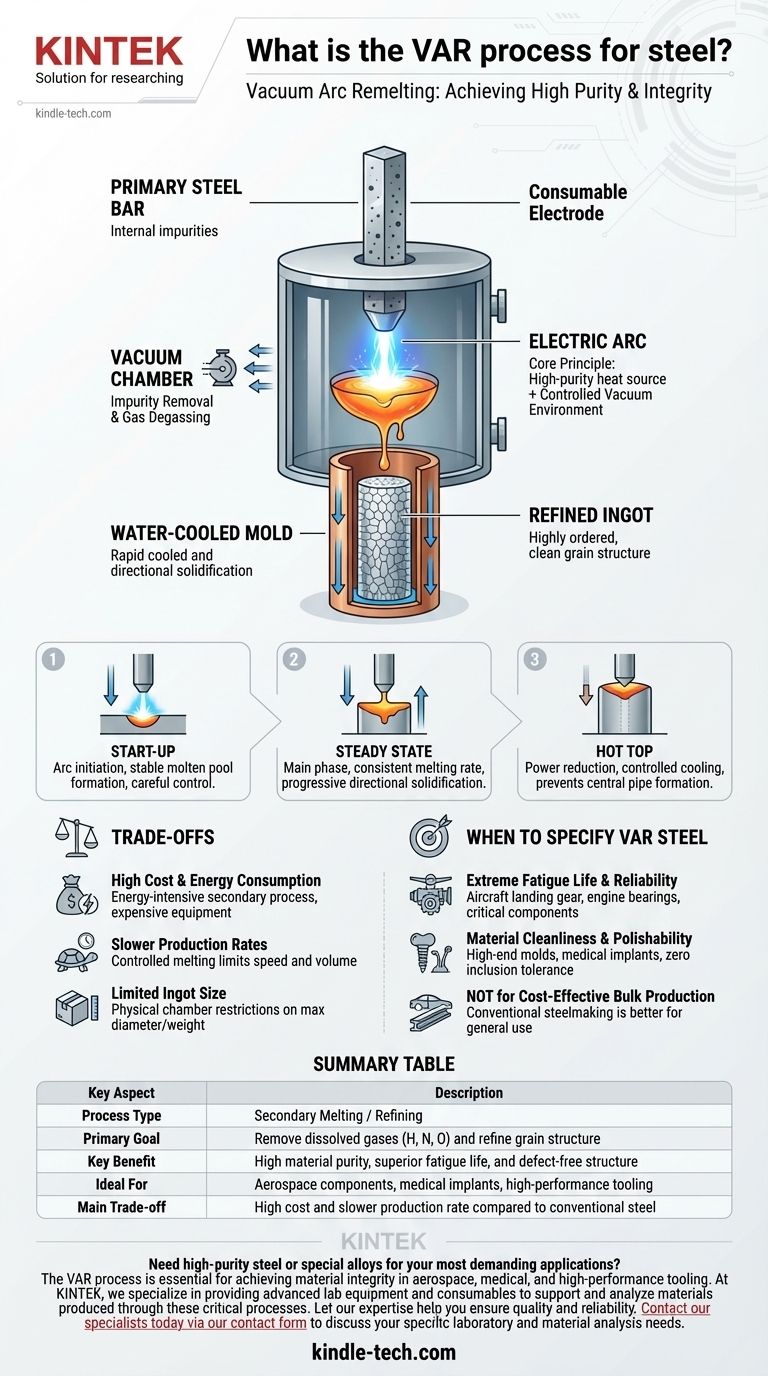

The Core Principle: How VAR Achieves Purity

The VAR process is a carefully orchestrated system where each component serves a distinct purpose in achieving material refinement. The magic lies in combining a high-purity heat source with a controlled environment.

The Consumable Electrode

The starting material for VAR is a solid bar of steel called a consumable electrode. This electrode has already been produced through a primary melting process. The goal of VAR is to improve upon this initial quality.

The Vacuum Environment

The entire process takes place inside a sealed, water-cooled chamber under a high vacuum. This vacuum is critical, as it draws out dissolved gases like hydrogen, nitrogen, and oxygen from the molten metal, which are primary sources of internal defects and brittleness in standard steels.

The Electric Arc

A high-current DC power supply is used to strike an electric arc between the bottom tip of the consumable electrode and a shallow pool of molten metal in the base of the mold. This arc generates intense, localized heat, causing the electrode tip to melt in a controlled, drip-by-drip manner.

The Water-Cooled Mold

The molten metal drips into a water-cooled copper mold, or crucible. Because copper has very high thermal conductivity, it rapidly draws heat away from the molten steel. This forces the new ingot to solidify directionally, from the bottom up, promoting a uniform and refined crystal structure.

A Step-by-Step Look at the VAR Process

The remelting operation is managed in three distinct phases to ensure the final ingot is sound from top to bottom.

Stage 1: Start-Up

The process begins by lowering the electrode into the crucible and striking the arc. A small amount of molten metal forms a pool at the bottom of the water-cooled mold, which initiates the remelting cycle. This initial phase is carefully controlled to establish a stable foundation for the ingot.

Stage 2: Steady State

This is the main phase of the process. The electrode is continuously and slowly lowered as its tip melts, maintaining a consistent arc length and melting rate. As metal drips into the mold, the new ingot solidifies progressively upwards, creating a highly organized grain structure with minimal segregation of alloying elements.

Stage 3: Hot Top

As the electrode is nearly consumed, the power is gradually reduced. This final stage, known as the "hot top," ensures the top surface of the ingot solidifies properly. This controlled cooling prevents the formation of a central shrinkage cavity, or "pipe," which would otherwise render the top portion of the ingot unusable.

Understanding the Trade-offs

While VAR produces exceptionally high-quality material, its benefits come with significant considerations. It is a specialized process, not a method for bulk steel production.

High Cost and Energy Consumption

VAR is an energy-intensive secondary process performed on metal that has already been melted once. The sophisticated vacuum equipment and high power requirements make VAR steel significantly more expensive than conventionally produced grades.

Slower Production Rates

Compared to primary steelmaking, VAR is a very slow process. The controlled melting and solidification rates, which are key to its success, inherently limit the speed and volume of production.

Limited Ingot Size

The physical size of the vacuum chamber and crucible restricts the maximum diameter and weight of the ingots that can be produced. This can be a limitation for applications requiring very large monolithic components.

When to Specify VAR Steel

Choosing a VAR-processed material is a decision driven entirely by the performance requirements of the final application.

- If your primary focus is extreme fatigue life and reliability: Specify VAR for components like aircraft landing gear, engine bearings, or crankshafts where internal defects could lead to catastrophic failure.

- If your primary focus is material cleanliness and polishability: VAR is ideal for high-end plastic injection molds and medical implants, where microscopic inclusions cannot be tolerated.

- If your primary focus is cost-effective bulk production: VAR is the wrong choice; conventional steelmaking processes are far more suitable for general construction, automotive bodies, and structural applications.

Ultimately, VAR is the definitive choice when material integrity and performance cannot be compromised.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process Type | Secondary Melting / Refining |

| Primary Goal | Remove dissolved gases (H, N, O) and refine grain structure |

| Key Benefit | High material purity, superior fatigue life, and defect-free structure |

| Ideal For | Aerospace components, medical implants, high-performance tooling |

| Main Trade-off | High cost and slower production rate compared to conventional steel |

Need high-purity steel or special alloys for your most demanding applications? The VAR process is essential for achieving the material integrity required in aerospace, medical, and high-performance tooling. At KINTEK, we specialize in providing the advanced lab equipment and consumables needed to support and analyze materials produced through these critical processes. Let our expertise help you ensure quality and reliability. Contact our specialists today via our contact form to discuss your specific laboratory and material analysis needs.

Visual Guide

Related Products

- Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

People Also Ask

- What is the necessity of achieving a high vacuum level of 10^-5 mbar? Ensure Purity in EHEAs Melting.

- What is the difference between combustion pyrolysis and gasification? A Guide to Thermal Conversion Technologies

- What is vacuum based deposition? Achieve High-Purity, Performance Coatings for Your Products

- What is an overheated brazed joint indicated by? Signs of a Failed Brazing Process

- What are the advantages of using a vacuum drying oven for rice husk? Preserve Biomass Quality and Purity

- Why is a vacuum drying oven essential in ferrate(VI) preparation? Preserve Chemical Integrity with Low-Temp Drying

- Can aluminum and steel be brazed together? Master the Complex Joining Process

- What is the purpose of sinter? Build Strong, Complex Parts from Powder