In electron beam (e-beam) evaporation, the typical accelerating voltage is between 4 and 10 kilovolts (kV). While this is a common range for many applications, some specialized systems may operate at voltages as high as 30 kV. This high voltage accelerates a beam of electrons to a very high velocity, giving them the kinetic energy needed to vaporize the source material upon impact.

The core principle is straightforward: the high voltage is not an arbitrary parameter, but the fundamental control knob for imparting enough energy into an electron beam to vaporize even the most resilient materials for thin-film deposition.

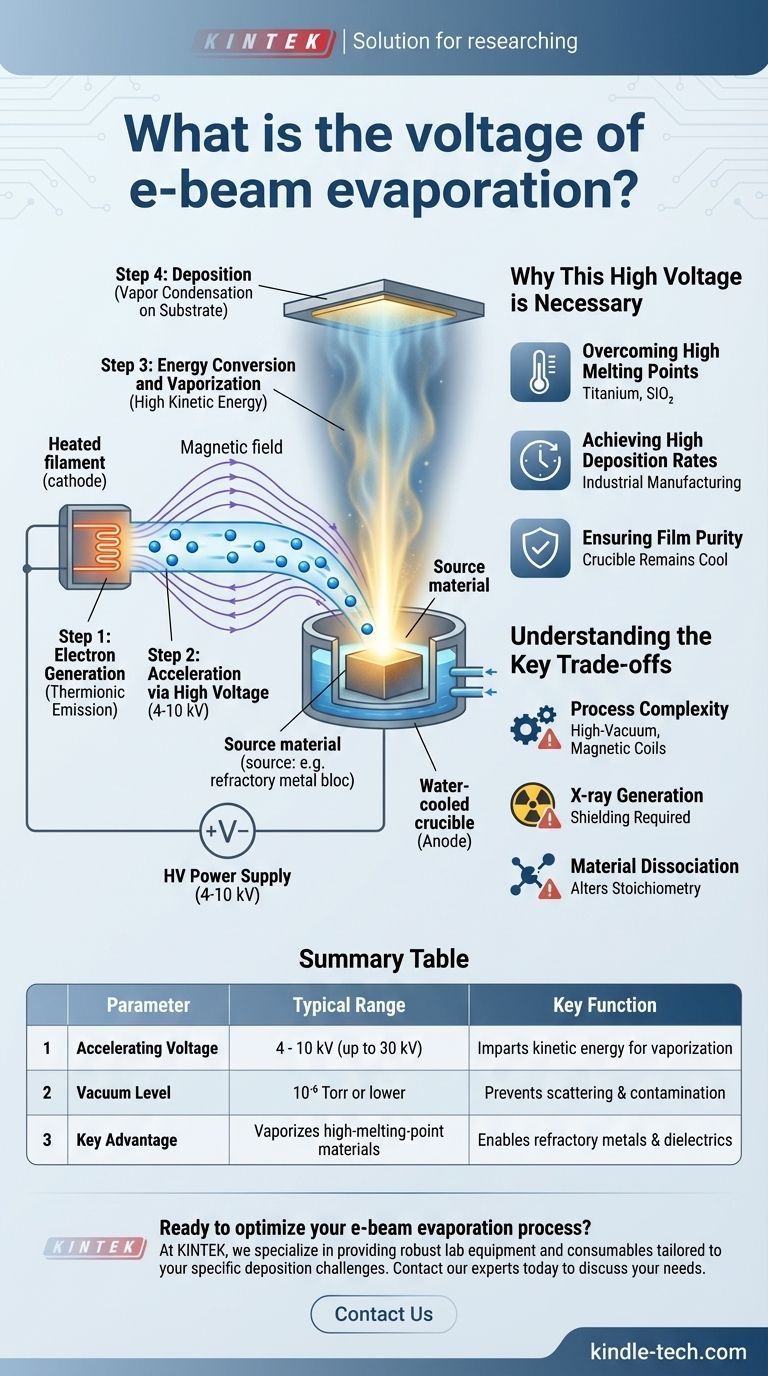

How Voltage Drives the Evaporation Process

E-beam evaporation is a physical vapor deposition (PVD) method that relies on converting the kinetic energy of electrons into thermal energy. The accelerating voltage is the primary factor that determines this energy transfer.

Step 1: Electron Generation

A tungsten filament, acting as a cathode, is heated to a high temperature. This causes it to release a cloud of electrons through a process called thermionic emission.

Step 2: Acceleration via High Voltage

A strong electric field is established between the cathode and the source material (the anode) by applying a high voltage, typically in the 4-10 kV range. This potential difference forcefully accelerates the emitted electrons toward the source material.

Step 3: Energy Conversion and Vaporization

The high-velocity electrons strike the evaporant material, which is held in a water-cooled copper hearth or crucible. Upon impact, their immense kinetic energy is instantly converted into intense, localized heat, raising the material's surface temperature past its boiling point and causing it to vaporize.

Step 4: Deposition

The resulting vapor travels in a straight line through the high-vacuum chamber until it condenses on the cooler surface of a substrate, forming a highly pure and dense thin film.

Why This High Voltage is Necessary

The use of a multi-kilovolt accelerating potential is essential for the versatility and quality that define e-beam evaporation. It offers distinct advantages over other deposition methods.

Overcoming High Melting Points

Many advanced materials used in aerospace, optics, and electronics—such as titanium, silicon dioxide (SiO₂), or hafnium oxide (HfO₂) — have extremely high melting points. The energy delivered by a high-voltage electron beam is one of the few methods capable of efficiently vaporizing them.

Achieving High Deposition Rates

The power of the electron beam (a function of both voltage and beam current) directly correlates to the evaporation rate. High voltage allows for high-power beams, enabling rapid deposition that is crucial for industrial and high-volume manufacturing.

Ensuring Film Purity

The electron beam's energy is focused on a small spot within the crucible. This means only the source material itself is heated, while the surrounding crucible remains cool. This prevents contamination from the crucible, leading to exceptionally pure deposited films.

Understanding the Key Trade-offs

While powerful, the high-voltage nature of e-beam evaporation introduces specific complexities that must be managed for successful operation.

Process Complexity

E-beam systems require a high-voltage power supply, a high-vacuum environment (typically 10⁻⁶ Torr or lower), and magnetic coils for steering the beam. This makes them inherently more complex and costly than simpler methods like thermal evaporation.

X-ray Generation

A known byproduct of high-energy electrons striking a solid target is the generation of X-rays. Systems must be properly shielded to ensure operator safety, a critical consideration that is not a factor in lower-energy deposition techniques.

Material Dissociation

For some complex compound materials, the intense, localized heating can cause molecules to break apart, or "dissociate." This can alter the stoichiometry of the deposited film, requiring careful process control and sometimes the introduction of a reactive gas to compensate.

Making the Right Choice for Your Goal

The optimal voltage is not a single number but a parameter that is tuned based on the material being deposited and the desired film properties.

- If your primary focus is depositing refractory metals (e.g., Tungsten, Tantalum): You will likely operate at the higher end of the voltage and beam current range to supply enough power to reach vaporization temperatures.

- If your primary focus is standard metals or dielectrics (e.g., Aluminum, SiO₂): A moderate voltage is typically sufficient, with the focus shifting to precise control of the beam current to maintain a stable deposition rate.

- If your primary focus is precision optical coatings: You need meticulous control over both voltage and beam parameters to manage film stress and achieve the exact refractive index required.

Ultimately, the accelerating voltage is the primary lever used to control the energy delivered in the e-beam evaporation process, making it a powerful and versatile tool for advanced thin-film deposition.

Summary Table:

| Parameter | Typical Range | Key Function |

|---|---|---|

| Accelerating Voltage | 4 - 10 kV (up to 30 kV) | Imparts kinetic energy to electrons for vaporization |

| Vacuum Level | 10⁻⁶ Torr or lower | Prevents electron scattering and contamination |

| Key Advantage | Vaporizes high-melting-point materials | Enables deposition of refractory metals and dielectrics |

Ready to optimize your e-beam evaporation process? The precise control of accelerating voltage is critical for achieving high-purity, high-performance thin films. At KINTEK, we specialize in providing robust lab equipment and consumables tailored to your specific deposition challenges. Whether you are working with refractory metals, dielectrics, or precision optical coatings, our expertise ensures you get the right system for your application.

Contact our experts today via our Contact Form to discuss how we can help you achieve superior deposition results and enhance your laboratory's capabilities.

Visual Guide

Related Products

- Electron Beam Evaporation Coating Conductive Boron Nitride Crucible BN Crucible

- Molybdenum Tungsten Tantalum Evaporation Boat for High Temperature Applications

- Hemispherical Bottom Tungsten Molybdenum Evaporation Boat

- Aluminized Ceramic Evaporation Boat for Thin Film Deposition

- Tungsten Evaporation Boat for Thin Film Deposition

People Also Ask

- Why is a boron nitride coating applied to alumina crucibles for LLZO? Ensure High Purity and Protect Your Lab Equipment

- What is the container that holds the metal source material called in e-beam evaporation? Ensure Purity and Quality in Your Thin-Film Deposition

- How source material is evaporated during deposition? A Guide to Resistive vs. E-Beam Methods

- What is the difference between thermal and electron beam evaporation? Unlock the Right Thin Film Deposition Method

- What materials are used in electron beam evaporation? Master High-Purity Thin Film Deposition