At its core, Chemical Vapor Deposition (CVD) is a process for building a high-quality, solid thin film on a surface. It works by introducing specific reactive gases, known as precursors, into a controlled chamber containing the object to be coated (the substrate). These gases then undergo a chemical reaction at the substrate's surface, depositing the desired material layer-by-layer while a gas flow removes unwanted byproducts.

The fundamental principle of CVD is not simply spraying a coating, but rather constructing a material atom-by-atom from the gas phase. It transforms volatile chemical precursors into a solid, high-performance film directly on a target surface through precisely controlled chemical reactions.

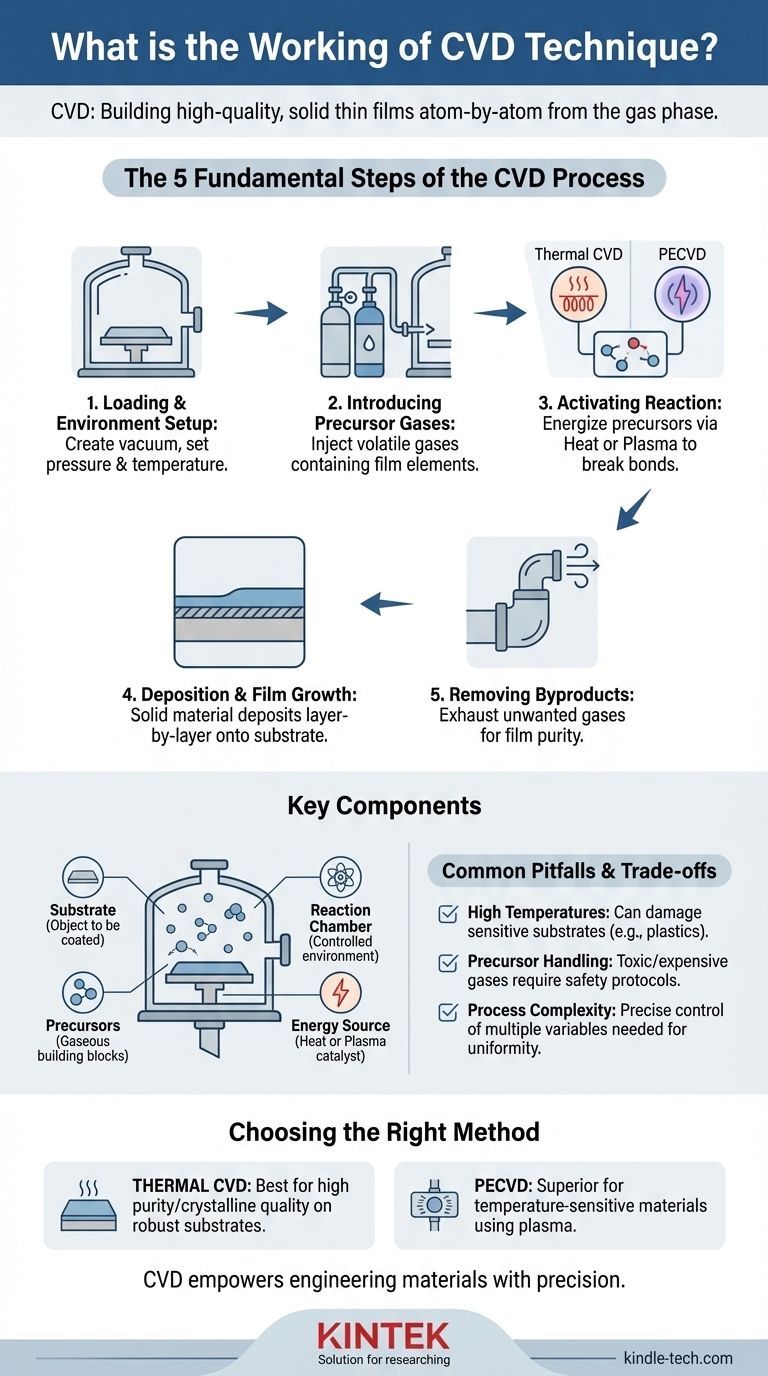

The Fundamental Steps of the CVD Process

To understand how CVD works, it's best to break it down into a sequence of controlled events. Each step is critical for achieving a uniform, dense, and pure final film.

Step 1: Loading and Establishing the Environment

First, the substrate—the material to be coated—is placed inside a sealed reaction chamber. The environment is then carefully controlled, often by creating a vacuum and then setting a specific pressure and temperature.

This initial control is crucial because it removes contaminants and sets the precise stage for the chemical reactions to follow.

Step 2: Introducing the Precursor Gases

One or more volatile precursor gases are injected into the chamber. These gases contain the chemical elements that will make up the final film.

For example, to deposit a silicon film, a gas like silane (SiH₄) might be used. Sometimes, a non-reactive carrier gas is used to help transport the precursors and maintain stable flow rates.

Step 3: Activating the Chemical Reaction

The precursor gases must be energized to react and decompose. This is the most critical step and is what differentiates various types of CVD.

Common activation methods include:

- Heat (Thermal CVD): The chamber and substrate are heated to a high temperature, providing the thermal energy needed to break the chemical bonds in the precursor gases.

- Plasma (Plasma-Enhanced CVD or PECVD): An RF plasma is generated in the chamber. This plasma creates highly reactive ions and radicals that can react at much lower temperatures than in thermal CVD.

Step 4: Deposition and Film Growth

As the precursors react or decompose at or near the heated substrate surface, the desired solid material "deposits" onto it.

This process builds up a thin film over time. Because the precursors are in a gaseous state, the film can grow uniformly over complex shapes, covering all exposed areas.

Step 5: Removing Byproducts

The chemical reactions almost always create unwanted volatile byproducts. For instance, in the silane example, hydrogen gas (H₂) is a byproduct.

A constant gas flow through the chamber, connected to an exhaust system, continuously removes these byproducts and any unreacted precursor gases, ensuring the purity of the growing film.

Understanding the Key Components and Their Roles

The CVD process relies on a few core components working in concert. Understanding each part clarifies how the entire system functions.

The Substrate

This is simply the object or material being coated. Its surface properties and temperature are critical factors that influence how the film adheres and grows.

The Precursors

These are the building blocks of the film, delivered in gaseous form. The choice of precursor chemicals is vital as it determines the composition of the final coating and the reaction byproducts.

The Reaction Chamber

This is the heart of the system—a sealed container that allows for precise control over pressure, temperature, and the gas atmosphere. The chamber material must be able to withstand the process conditions without contaminating the film.

The Energy Source

Whether it's a heating element or a plasma generator, the energy source is the catalyst that drives the chemical transformation from gas to solid. It dictates the rate and nature of the deposition.

Common Pitfalls and Technical Trade-offs

While powerful, CVD is not a universally perfect solution. Its effectiveness is governed by a series of technical trade-offs.

High Temperatures Can Be a Constraint

Traditional thermal CVD often requires very high temperatures (several hundred to over a thousand degrees Celsius). This can damage or warp temperature-sensitive substrates, such as plastics or certain electronic components.

Precursor Handling and Cost

The specialized gases used as precursors can be expensive, toxic, or highly flammable. This requires significant investment in safety infrastructure and careful handling protocols.

Process Complexity and Control

Achieving a high-quality, uniform film requires precise control over multiple variables simultaneously: gas flow rates, temperature, pressure, and chamber cleanliness. Any deviation can lead to defects in the final product.

How to Apply This to Your Project

Your choice of CVD method depends entirely on the requirements of your substrate and the desired properties of the final film.

- If your primary focus is high purity and crystalline quality: Thermal CVD is often the best choice, provided your substrate can withstand the high processing temperatures.

- If your primary focus is coating temperature-sensitive materials: Plasma-Enhanced CVD (PECVD) is the superior option, as it enables deposition at much lower temperatures.

- If your primary focus is uniform coverage on complex 3D shapes: The gaseous nature of the CVD process makes it inherently well-suited for creating conformal coatings that are difficult to achieve with line-of-sight methods.

Ultimately, mastering the CVD process empowers you to engineer materials with precision from the molecular level up.

Summary Table:

| CVD Process Step | Key Function |

|---|---|

| 1. Environment Setup | Load substrate and establish controlled pressure/temperature. |

| 2. Gas Introduction | Inject volatile precursor gases into the chamber. |

| 3. Reaction Activation | Energize gases via heat or plasma to initiate decomposition. |

| 4. Film Deposition | Solid material deposits layer-by-layer onto the substrate. |

| 5. Byproduct Removal | Exhaust system removes unwanted gases, ensuring film purity. |

Ready to Engineer Your Materials with Precision?

Understanding the intricacies of CVD is the first step. Implementing it successfully requires the right equipment and expertise. KINTEK specializes in high-performance lab equipment and consumables for all your deposition needs, whether you're working with thermal CVD for high-purity films or PECVD for temperature-sensitive substrates.

Our solutions help you achieve uniform, high-quality coatings for applications in semiconductors, research, and advanced materials. Let our experts guide you to the optimal setup for your project.

Contact KINTEK today to discuss how our CVD systems can advance your laboratory's capabilities.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- What does the deposition rate indicate? Mastering the Speed vs. Quality Balance in Thin Film Deposition

- What is the catalyst for CNT growth? Unlock the Key to High-Quality Carbon Nanotube Synthesis

- Why is a high-precision vacuum pump system essential for iCVD? Achieve Superior Film Purity and Uniformity

- What is CVD method for graphene? A Scalable Process for High-Quality, Large-Area Films

- What are the primary manufacturing technologies for synthetic diamonds? Compare HPHT, CVD, and Niche Methods

- What is the difference between CVD and PVD semiconductor? A Guide to Choosing the Right Thin-Film Process

- What is the specific function of the metal filament in HF-CVD? Key Roles in Diamond Growth

- What are some specific applications of High-Density Plasma CVD (HDP-CVD)? Master Gap-Fill for Semiconductors