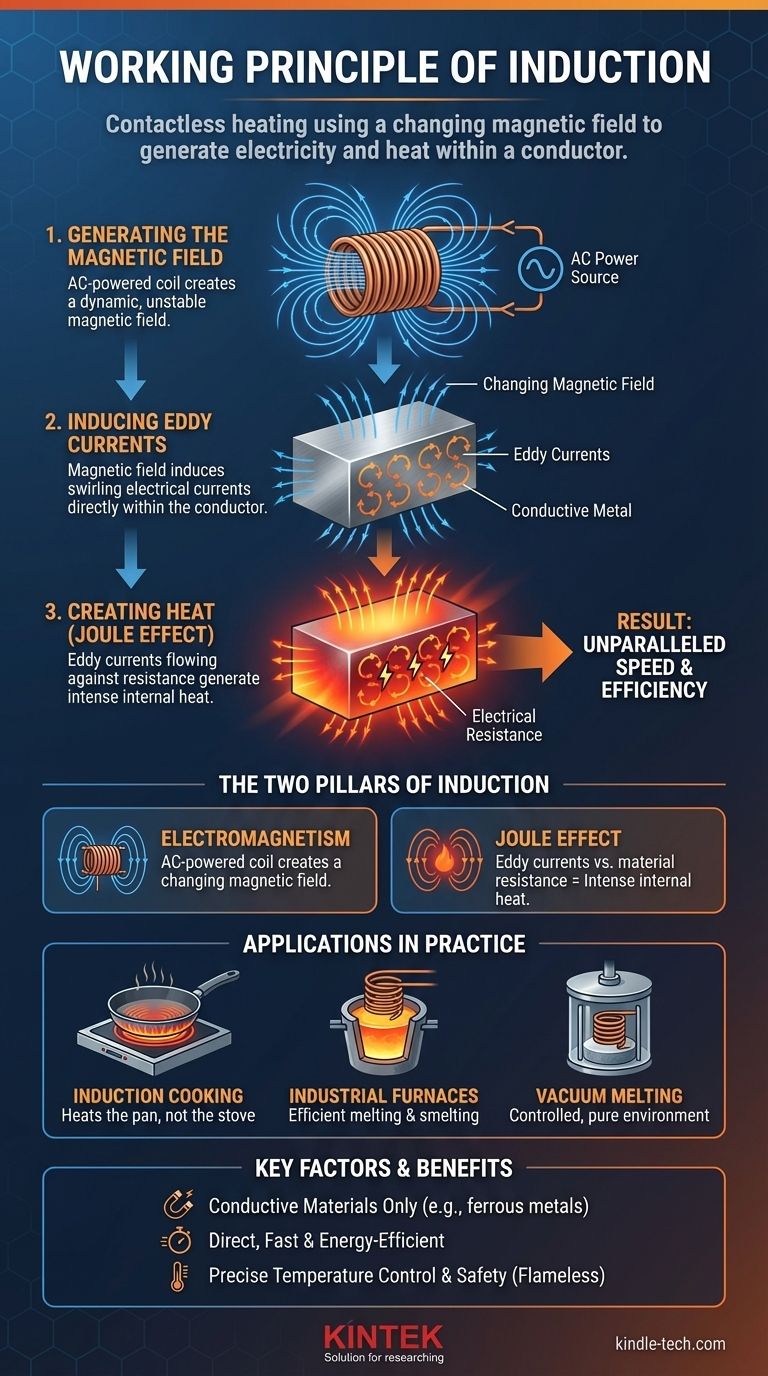

The working principle of induction is the use of a changing magnetic field to generate electricity within a conductor, which in turn creates heat. An alternating current (AC) is passed through a coil, producing a dynamic magnetic field. When a conductive material, like an iron pan or metal in a furnace, is placed within this field, the field induces swirling electrical currents—known as eddy currents—directly within the material, heating it from the inside out.

Induction is fundamentally a method of contactless heating. Instead of using a flame or a hot surface, it turns the target object into its own heat source by leveraging the principles of electromagnetism and electrical resistance, resulting in unparalleled speed and efficiency.

The Two Pillars of Induction: Electromagnetism and Resistance

To grasp how induction works, we need to look at two fundamental physical principles working in sequence. The entire process transforms electrical energy into magnetic energy, and finally into thermal energy.

Step 1: Generating the Magnetic Field

The process begins with an induction coil, typically made of copper.

An alternating current (AC) is sent through this coil. Because the current is constantly and rapidly changing direction, it generates a dynamic and unstable magnetic field around the coil.

Step 2: Inducing Eddy Currents

This fluctuating magnetic field expands and collapses, passing through any conductive material placed nearby.

According to Maxwell's equations of electromagnetism, this changing magnetic field induces small, circular electrical currents within the conductor. These are called eddy currents.

You can visualize these currents as tiny whirlpools of electricity swirling inside the material.

Step 3: Creating Heat Through the Joule Effect

Every conductor has some natural electrical resistance. As the induced eddy currents flow through the material, they encounter this resistance.

This friction between the flowing electrons and the material generates intense heat. This phenomenon is known as the Joule Effect, and it is the final step that converts electrical energy into useful thermal energy.

How Induction is Applied in Practice

The same core principle applies across a vast range of applications, from home kitchens to heavy industry, with the main difference being the scale and power involved.

Induction Cooking: Heating the Pan, Not the Stove

In an induction cooktop, the coil is located beneath the ceramic glass surface. When you place an iron-based (ferrous) pot on top, the magnetic field induces eddy currents directly into the base of the pot.

The pot itself becomes the source of heat, which is then transferred to the food inside via conduction. The cooktop surface remains cool because the magnetic field does not affect it.

Industrial Furnaces: The Transformer Analogy

A core-type induction furnace operates exactly like a power transformer.

A primary coil surrounds an iron core. The "secondary coil" is a closed loop formed by the molten metal itself. The immense current induced in this metal loop generates the heat required for melting and smelting, achieving power efficiencies of up to 98%.

Vacuum Melting: Induction in a Controlled Environment

For metals that react with oxygen or nitrogen, the entire induction process can be placed inside a vacuum chamber.

This allows for the melting of highly reactive alloys without contamination. The principle remains identical: a coil induces eddy currents in the metal charge, heating and melting it in a pure, airless environment.

Understanding the Trade-offs

Induction heating is powerful, but its effectiveness is dictated by a clear set of physical constraints and benefits.

The Critical Role of Material

The single greatest factor is material dependency. The target object must be electrically conductive to allow eddy currents to form.

For cooking, this is why pans must have a ferrous (iron or steel) base. Materials like copper and aluminum are conductive, but their magnetic properties make them less suitable for standard cooktops. Glass, ceramic, and stone will not heat at all.

Unmatched Efficiency and Speed

The primary advantage of induction is its direct heating method. Energy is generated inside the workpiece, not transferred to it from an external source.

This minimizes heat loss to the surrounding environment, making the process incredibly fast and energy-efficient compared to conventional heating.

Precision and Safety

Heating is instantaneous. It begins the moment the magnetic field is generated and stops the moment it is turned off.

This provides exceptionally precise temperature control. In applications like cooking, the lack of an open flame or a hot surface (other than the pan itself) makes it a significantly safer method.

Making the Right Choice for Your Goal

Understanding the core mechanism allows you to determine when induction is the optimal solution.

- If your primary focus is speed and energy efficiency: Induction is a leading choice because it transfers energy directly into the material without contact or waste.

- If you are working with non-conductive materials like ceramic or glass: Induction will not work, and you must rely on traditional heating methods like conduction, convection, or radiation.

- If your primary focus is precision and safety: The instantaneous and flameless nature of induction provides superior control and a safer operating environment.

By turning a material into its own heater, induction offers a clever and powerful application of physics to heat things cleanly, quickly, and with remarkable efficiency.

Summary Table:

| Principle | Key Component | Result |

|---|---|---|

| Electromagnetism | AC-powered coil creates a changing magnetic field. | Induces swirling electrical currents (eddy currents) in a conductor. |

| Joule Effect | Eddy currents flow against the material's electrical resistance. | Generates intense, internal heat directly within the material. |

Need precise, efficient, and safe heating for your laboratory processes?

KINTEK specializes in high-performance lab equipment, including induction heating systems designed for accuracy and reliability. Whether you are melting metals, conducting heat treatment, or require controlled thermal processing, our solutions deliver unmatched speed and energy efficiency.

Contact us today to discuss how our induction technology can enhance your laboratory's capabilities and productivity. Get in touch via our contact form to speak with an expert!

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- What are the advantages of using vacuum hot pressing for CoCrCuFeNi? Superior Strength via Microstructural Control

- What are the benefits of using a vacuum hot pressing furnace to synthesize high-density Mo2Ga2C? Achieve 98.8% Density.

- What are the primary functions of a vacuum hot press furnace? Optimize WC/Cu-Zr-Ti Composite Consolidation

- What role does a vacuum hot pressing sintering furnace play in the fabrication of CuCrFeMnNi alloys? Achieve High Purity

- What are the advantages of using a Vacuum Hot-Pressing Furnace for Ti-6Al-4V? Achieve Forged-Like Strength & Purity