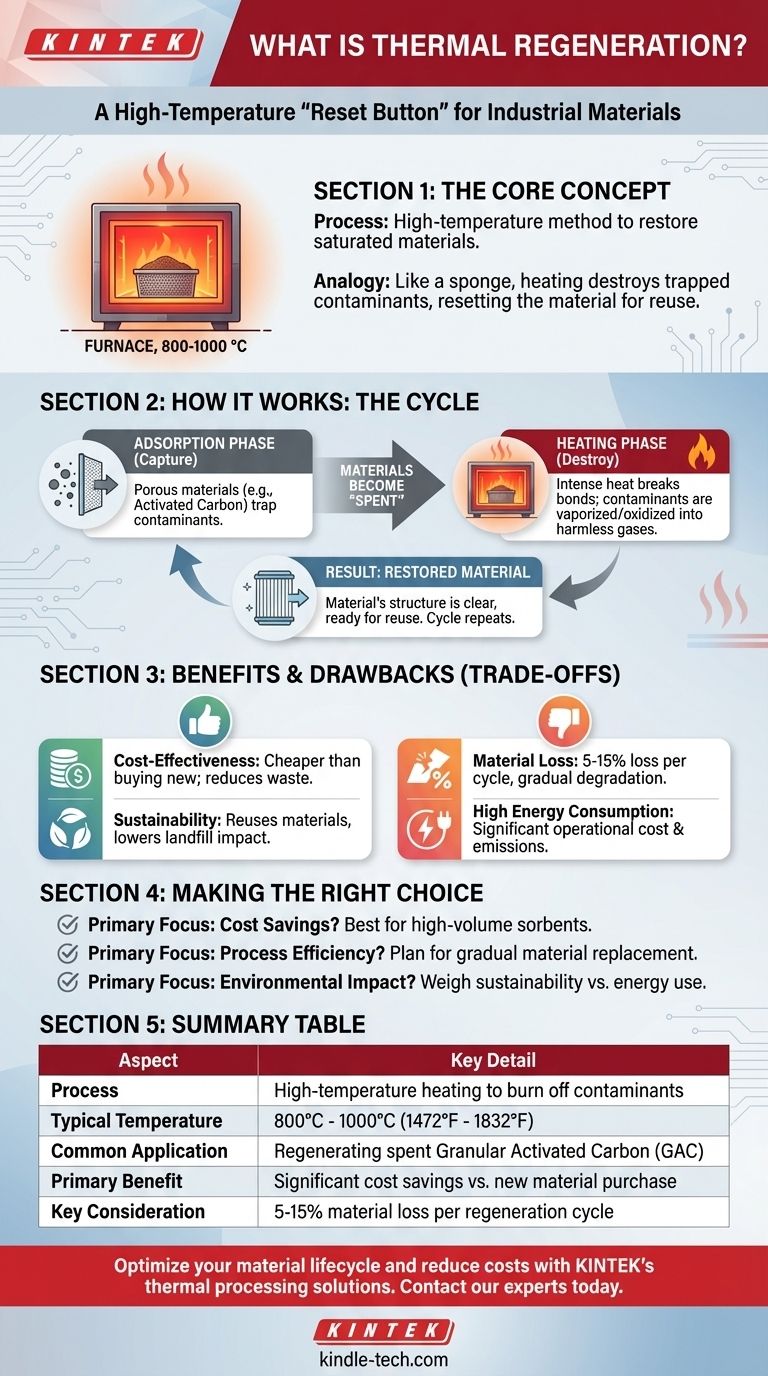

In short, thermal regeneration is a high-temperature process used to restore a material to its original, effective state after it has become saturated or "spent." It is most commonly used to clean industrial materials like activated carbon by using extreme heat (often 800-1000 °C) in a furnace to burn off or vaporize the contaminants that the material has adsorbed.

Thermal regeneration acts as a high-temperature "reset button" for materials that function like sponges. By heating the spent material, you effectively destroy and remove the trapped contaminants, restoring the material’s capacity to be used again.

How Thermal Regeneration Works: The Core Mechanism

To understand thermal regeneration, you must first understand the job the material was doing. The process is a cycle of capture and release, driven by changes in temperature.

The Adsorption Phase: Capturing Contaminants

Many industrial processes use porous materials, like Granular Activated Carbon (GAC), to purify liquids or gases. These materials have a vast internal surface area with active sites that trap and hold onto unwanted organic substances—a process called adsorption.

Over time, these active sites become filled, and the material is considered "spent" or saturated, losing its effectiveness.

The Heating Phase: Destroying the Contaminants

This is where thermal regeneration comes in. The spent material is removed from service and placed into a high-temperature furnace, often in a low-oxygen environment.

The intense heat, typically between 800°C and 1000°C (1472°F to 1832°F), provides the energy needed to break the bonds holding the adsorbed contaminants. These organic substances are either vaporized or, more commonly, oxidized (chemically destroyed) and converted into harmless gases.

The Result: A Restored Material

After the heating and cool-down cycle, the contaminants are gone. The material's porous structure and active sites are now clear and available again.

This "regenerated" material is ready to be put back into service, capable of adsorbing new contaminants. This cycle of use and regeneration can be repeated multiple times.

Understanding the Trade-offs

While highly effective, thermal regeneration is not a perfect process. It involves a clear set of benefits and drawbacks that are critical to consider.

Pro: Cost-Effectiveness and Sustainability

The primary driver for thermal regeneration is economics. Regenerating and reusing an expensive material like activated carbon is significantly cheaper than continuously disposing of spent material and purchasing new supplies. It also reduces landfill waste, offering a clear environmental benefit.

Con: Material Loss and Degradation

The process is not 100% efficient. Each high-temperature cycle inevitably causes some physical degradation and burnout of the host material itself. Typically, there is a 5-15% loss of carbon with each regeneration cycle, which gradually reduces its performance and lifespan.

Con: High Energy Consumption

Heating industrial-scale furnaces to 1000°C requires a massive amount of energy. This represents a significant operational cost and has its own environmental footprint, which must be weighed against the benefits of material reuse.

Making the Right Choice for Your Process

Deciding whether to implement thermal regeneration depends on balancing economic, operational, and environmental goals.

- If your primary focus is cost savings on high-volume materials: Thermal regeneration is often the most economically viable method for sorbents like activated carbon used in large-scale purification.

- If your primary focus is process efficiency: Account for the 5-15% material loss per cycle in your operational planning and budget for gradual replacement of the media over time.

- If your primary focus is environmental impact: Carefully weigh the sustainability benefit of reusing materials against the significant energy consumption and emissions of the regeneration furnace.

Ultimately, thermal regeneration is a powerful tool for extending the life of critical materials and reducing operational costs.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Process | High-temperature heating to burn off contaminants |

| Typical Temperature | 800°C - 1000°C (1472°F - 1832°F) |

| Common Application | Regenerating spent Granular Activated Carbon (GAC) |

| Primary Benefit | Significant cost savings vs. new material purchase |

| Key Consideration | 5-15% material loss per regeneration cycle |

Optimize your material lifecycle and reduce costs with KINTEK's thermal processing solutions.

Thermal regeneration is a powerful strategy for laboratories and industrial facilities using sorbents like activated carbon. By restoring spent materials, you can dramatically cut operational expenses and minimize waste. KINTEK specializes in the high-temperature lab equipment and consumables needed to implement this process efficiently and reliably.

Contact our experts today to discuss how our furnaces and thermal systems can help you achieve sustainable, cost-effective material regeneration for your specific application.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- How do a quartz tube reactor and atmosphere furnace collaborate in Co@NC pyrolysis? Master Precision Synthesis

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance