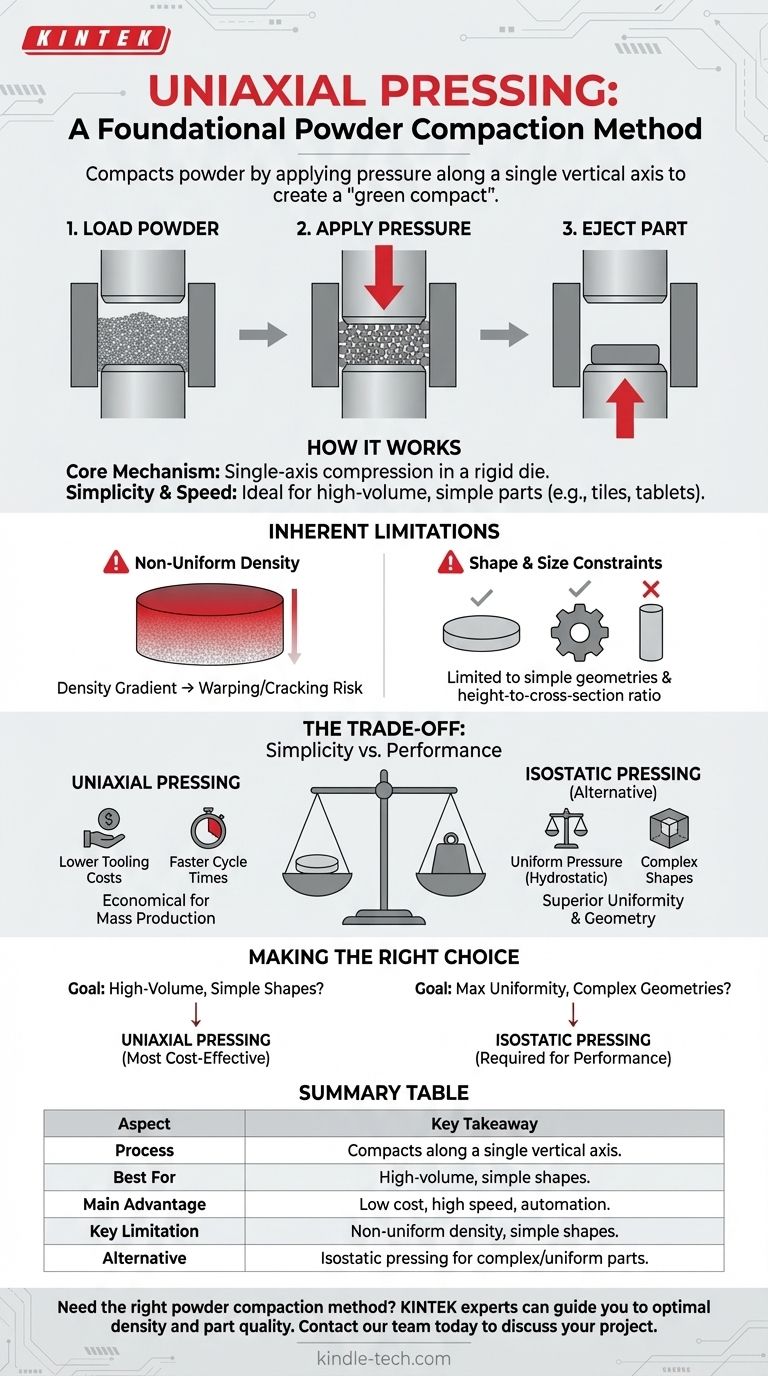

In the simplest terms, uniaxial pressing is a manufacturing process that compacts a powder by applying pressure along a single vertical axis. This is typically done by confining the powder within a rigid die and then compressing it with one or more moving punches. The result is a pre-formed, solid object, often called a "green compact," which is then ejected from the die for further processing like sintering.

Uniaxial pressing is a foundational powder compaction method valued for its speed and low cost. Its defining characteristic—applying force in one direction—is both its greatest strength for simple, high-volume production and its primary limitation, leading to challenges with density uniformity and shape complexity.

How Uniaxial Pressing Works

The Core Mechanism

Uniaxial pressing involves a straightforward mechanical action. A precise amount of powder is loaded into a die cavity, which defines the part's lateral dimensions.

One or two rigid punches then move along a single axis to compress the powder. The final height of the part is determined by the distance the punches travel.

Simplicity and Speed

The single-axis motion makes this process highly suitable for automation and rapid cycling. This simplicity is a key reason for its widespread use in producing high volumes of relatively simple parts like ceramic tiles, pharmaceutical tablets, and basic mechanical components.

The Inherent Limitations of Single-Axis Pressure

The primary drawbacks of uniaxial pressing stem directly from its single-axis nature. The way force is transmitted through a powder creates predictable challenges.

Non-Uniform Density

As the punch applies pressure, friction between the powder particles and the die walls prevents the force from being distributed evenly throughout the compact.

Particles closer to the moving punch are compacted more densely than those farther away. This creates a density gradient within the part, which can lead to warping or cracking during subsequent heating (sintering) steps.

Shape and Size Constraints

Uniaxial pressing is limited to shapes that can be easily ejected from the die. This means complex geometries with undercuts or transverse holes are not possible.

Furthermore, there is a practical limit to a part's cross-section-to-height ratio. Very tall, thin parts are difficult to produce because the die-wall friction becomes too significant, leading to very poor density at the part's center.

Understanding the Trade-offs: Simplicity vs. Performance

Choosing a compaction method involves balancing manufacturing efficiency with the required performance of the final component. Uniaxial pressing presents a clear set of trade-offs compared to more advanced methods.

The Advantage: Lower Cost and Complexity

Compared to alternatives like isostatic pressing (which applies pressure uniformly from all directions), uniaxial pressing has significantly lower tooling costs and less process complexity.

The machinery is simpler and the cycle times are faster, making it the most economical choice for mass production of suitable parts.

The Disadvantage: Compromised Uniformity

The cost and speed advantages come at the price of uniformity. Isostatic pressing overcomes the key limitations of uniaxial pressing by applying pressure hydrostatically, resulting in a much more uniform compaction.

This uniform pressure allows for the creation of more complex shapes and eliminates the height-to-diameter ratio limitations inherent to the uniaxial process.

Making the Right Choice for Your Goal

Your application's specific requirements will determine if uniaxial pressing is the appropriate method.

- If your primary focus is high-volume production of simple, flat shapes: Uniaxial pressing is the most cost-effective and efficient method available.

- If your primary focus is achieving maximum density uniformity or producing complex geometries: You must look to alternatives like isostatic pressing to meet your performance requirements.

Ultimately, understanding uniaxial pressing is about recognizing the fundamental trade-off between manufacturing efficiency and the geometric complexity of the final part.

Summary Table:

| Aspect | Key Takeaway |

|---|---|

| Process | Compacts powder along a single vertical axis in a rigid die. |

| Best For | High-volume production of simple shapes (e.g., tiles, tablets). |

| Main Advantage | Low cost, high speed, and suitability for automation. |

| Key Limitation | Non-uniform density due to die-wall friction, limiting part complexity. |

| Alternative | Isostatic pressing for complex shapes and uniform density. |

Need to choose the right powder compaction method for your lab's materials?

At KINTEK, we specialize in lab equipment and consumables, helping you select the perfect pressing solution for your specific application—whether it's for high-volume production or complex geometries. Our experts can guide you to achieve optimal density and part quality.

Contact our team today to discuss your project requirements and discover how KINTEK can enhance your laboratory's efficiency and results.

Visual Guide

Related Products

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Heat Press Machine

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Laboratory Manual Hydraulic Pellet Press for Lab Use

People Also Ask

- Can a hydraulic press shatter a diamond? Yes, and here's why hardness isn't toughness.

- What are the advantages and disadvantages of transfer moulding? Achieve Precision for Complex Thermoset Parts

- What is a pressed pellet? Achieve Accurate Sample Analysis with Proper Pellet Preparation

- How does a laboratory hydraulic press contribute to the electrochemical performance testing of LiMOCl4? Achieve Density

- What affects the speed of a hydraulic motor? Master the balance of flow rate and displacement

- How does a laboratory hydraulic press contribute to the preparation of shaped Fischer-Tropsch Synthesis catalysts?

- What role does a high-precision laboratory hydraulic press play in ICDP membranes? Optimize Ceramic Support Formation

- Why is hydraulic pressure important? Harnessing Immense Force with Simple Systems