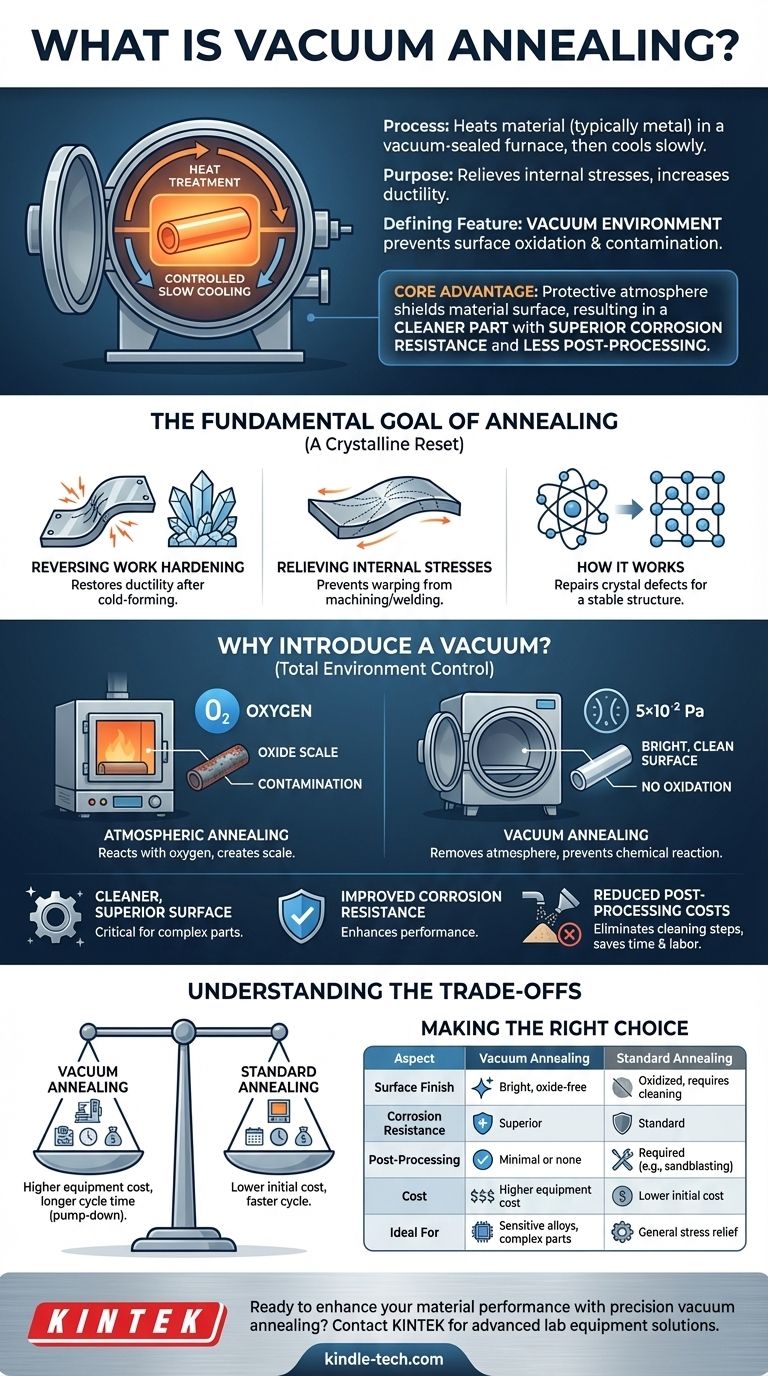

Vacuum annealing is a heat treatment process that heats a material, typically metal, within a vacuum-sealed furnace. The material is held at a specific high temperature and then cooled at a controlled, slow rate. This process relieves internal stresses and increases ductility, but its defining feature is the vacuum environment, which prevents surface oxidation and contamination during heating.

The core purpose of annealing is to make a material softer and more workable. Performing this process in a vacuum adds a critical advantage: it creates a protective atmosphere that shields the material’s surface, resulting in a cleaner part with superior corrosion resistance that requires significantly less post-processing.

The Fundamental Goal of Annealing

Before understanding the role of the vacuum, it's essential to understand the purpose of annealing itself. It is a foundational process used to modify a material's physical and sometimes electrical properties.

Reversing Work Hardening

When metals are bent, drawn, or cold-formed, their internal crystalline structure becomes stressed and distorted. This makes the material harder and stronger, but also more brittle and prone to cracking. Annealing reverses the effects of work hardening, restoring the material's ductility and allowing for further processing without failure.

Relieving Internal Stresses

Processes like machining, grinding, or welding introduce significant mechanical stresses into a material. These hidden stresses can cause a part to warp or distort during subsequent manufacturing steps or when put into service. Annealing provides a "reset," allowing the internal structure to relax into a stable, low-stress state.

How It Works: A Crystalline Reset

The annealing process involves heating the metal to a temperature where its atoms can move more freely, effectively repairing defects in the crystal lattice. By holding it at this temperature and then cooling it slowly, the crystals reform in a more uniform and less-stressed arrangement, resulting in a softer, more ductile material.

Why Introduce a Vacuum?

Adding a vacuum to the annealing process is about one thing: total control over the part's environment, specifically its surface.

Preventing Oxidation and Contamination

At the high temperatures required for annealing, most metals react readily with oxygen and other elements in the air. This reaction creates a layer of oxide scale on the surface. A vacuum furnace removes the atmosphere, achieving a working vacuum level as low as 5×10⁻² Pa, which starves the chemical reaction of the oxygen it needs.

The Benefit: A Cleaner, Superior Surface

By preventing oxidation, vacuum annealing produces parts with a bright, clean surface finish. This is not just cosmetic. For many applications, an oxide-free surface is critical for improving corrosion resistance and ensuring proper performance, especially on internal surfaces of complex parts like impellers or pumps.

Reducing Post-Processing Costs

Without a layer of oxide scale to remove, subsequent cleaning steps like sandblasting, grinding, or chemical acid baths are often eliminated. This directly translates to faster production cycles and lower costs, as it saves both labor and materials.

Understanding the Trade-offs

While powerful, vacuum annealing is not always the necessary choice. Its benefits must be weighed against practical considerations.

Equipment and Cost

Vacuum furnaces are inherently more complex and expensive to purchase and operate than standard atmospheric furnaces. The process requires pumps, seals, and precise controls to maintain the vacuum, which adds to the overall cost.

Process Cycle Time

Achieving and maintaining a deep vacuum adds time to the overall process cycle. The initial "pump-down" phase before heating can extend the total time a part spends in the furnace compared to atmospheric annealing.

When It's Overkill

For materials where surface finish is not a primary concern or for parts that will undergo significant machining after heat treatment, the benefits of a vacuum may not justify the added cost. In these cases, standard atmospheric annealing is often a more practical and cost-effective solution.

Making the Right Choice for Your Goal

Selecting the correct annealing process depends entirely on the final requirements for the component.

- If your primary focus is surface integrity and corrosion resistance: Vacuum annealing is the superior choice, particularly for sensitive alloys or parts with complex internal geometries where cleaning is difficult.

- If your primary focus is simply stress relief on a budget: Standard atmospheric annealing is often sufficient, provided that some surface oxidation and subsequent cleaning are acceptable.

- If your goal is to prepare for subsequent surface treatments: Vacuum annealing provides an ideally clean and active surface, making it the preferred preparatory step for processes like coating or nitriding.

Ultimately, choosing between atmospheric and vacuum annealing is a technical decision that balances the non-negotiable requirements of the part against the total cost of the manufacturing process.

Summary Table:

| Aspect | Vacuum Annealing | Standard Annealing |

|---|---|---|

| Surface Finish | Bright, oxide-free | Oxidized, requires cleaning |

| Corrosion Resistance | Superior | Standard |

| Post-Processing | Minimal or none | Required (e.g., sandblasting) |

| Cost | Higher equipment cost | Lower initial cost |

| Ideal For | Sensitive alloys, complex parts | General stress relief |

Ready to enhance your material performance with precision vacuum annealing?

At KINTEK, we specialize in providing advanced lab equipment and consumables tailored to your laboratory's unique needs. Our vacuum furnaces ensure your metals and alloys achieve superior surface integrity, reduced post-processing, and enhanced corrosion resistance—saving you time and cost in the long run.

Contact us today via our contact form to discuss how our solutions can optimize your heat treatment processes and deliver the quality your projects demand!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the role of Spark Plasma Sintering (SPS) furnaces in Ti-Nb-Zr alloys? Precision Engineering for Implants

- Why must a vacuum drying oven be used to treat graphite molds? Ensure Defect-Free Hot-Pressing Sintering

- What is the working principle of heat treatment furnace? A Guide to Controlled Material Transformation

- How does the isothermal holding function of high-temperature furnaces affect TLP bonding joints? Achieve Seamless Bonds

- What are the heat treatment processes carried out to the metals for? Tailor Metal Properties for Your Application

- Why is a double vacuum resistance furnace recommended for magnesium recovery? Ensuring Safety & Stability

- How hot can an industrial furnace get? Find the Right Temperature for Your Process

- Why must zirconium-niobium alloy sponges undergo vacuum heat treatment? Master the Key to High-Purity Alloy Production