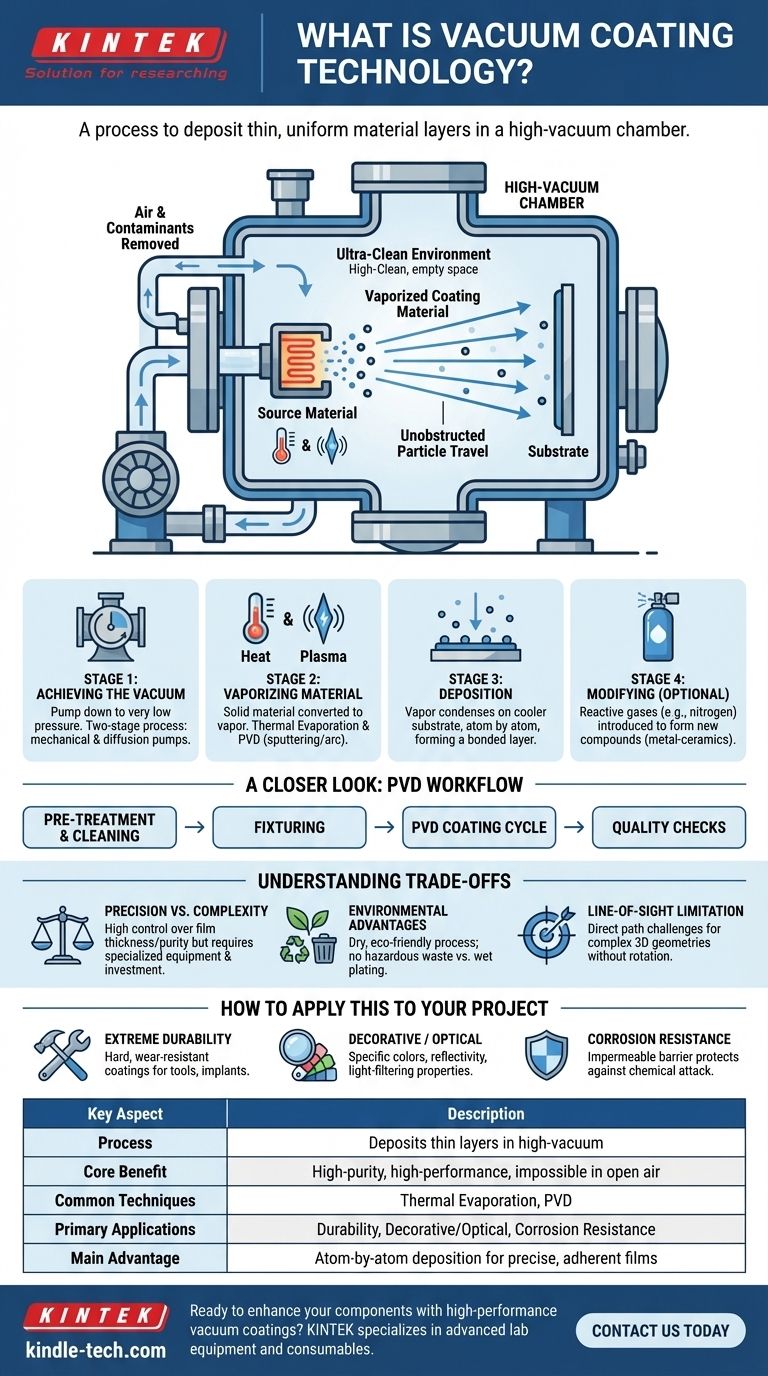

Vacuum coating is a family of processes used to deposit a very thin, uniform layer of material onto a surface, known as a substrate. This entire process takes place inside a high-vacuum chamber, which is the key element that enables the creation of high-purity, high-performance coatings that are not possible in open air.

The critical insight is that the vacuum itself is not just a setting, but the core enabler of the technology. By removing air and other contaminants, the vacuum creates an ultra-clean environment for vaporized coating material to travel unimpeded and bond perfectly, atom by atom, to a target surface.

Why is a Vacuum Essential?

Creating an Ultra-Clean Environment

The primary purpose of the vacuum is to remove air molecules, water vapor, and any other airborne particles from the chamber. Without a vacuum, these particles would contaminate the coating and interfere with the process.

Ensuring Unobstructed Particle Travel

Inside the vacuum, atoms of the coating material can travel in a straight line from their source to the substrate. This direct path is crucial for creating a dense, uniform, and highly adherent thin film.

The Core Vacuum Coating Process

Stage 1: Achieving the Vacuum

Before any coating can occur, the chamber must be pumped down to a very low pressure. This is typically a two-stage process using a mechanical pump for the initial low vacuum, followed by a diffusion pump to achieve the high vacuum state required.

Stage 2: Vaporizing the Source Material

A solid source material is converted into a vapor. This is the central step where different vacuum coating techniques diverge.

- Thermal Evaporation: The material is heated in a crucible until it melts and evaporates.

- Physical Vapor Deposition (PVD): The material is bombarded with ions from a plasma (sputtering) or vaporized by an electric arc discharge.

Stage 3: Deposition onto the Substrate

The vaporized atoms or molecules travel through the vacuum and condense on the cooler surface of the part being coated. This deposition occurs atom by atom, building a thin, bonded layer.

Stage 4: Modifying the Coating (Optional)

Reactive gases, such as nitrogen, can be precisely introduced into the chamber during the process. These gases react with the metal vapor to form new compounds (like metal-ceramics), allowing for coatings with specific mechanical, chemical, or optical properties.

A Closer Look: The PVD Workflow

Physical Vapor Deposition (PVD) is a modern and prominent example of vacuum coating technology.

The Industrial Process

A typical PVD process is a multi-step workflow designed for quality control. It includes pre-treatment and cleaning of the part, fixturing it inside the chamber, the PVD coating cycle itself, and post-process quality checks for thickness and adhesion.

Materials and Resulting Properties

Solid metals like titanium, zirconium, and chromium are vaporized and often combined with a reactive gas. The resulting thin film provides exceptional hardness, wear resistance, corrosion resistance, and specific decorative or optical finishes.

Understanding the Trade-offs

Precision vs. Complexity

Vacuum coating provides unparalleled control over film thickness and purity. However, this precision requires significant investment in specialized vacuum chambers, pumping systems, and control electronics.

Environmental Advantages

Compared to traditional wet plating processes like electroplating, PVD is a dry, environmentally friendly technology. It produces no hazardous waste materials, making it a cleaner manufacturing choice.

Line-of-Sight Limitation

In many vacuum coating methods, the coating material travels in a straight line from the source to the substrate. This can make it challenging to achieve a perfectly uniform coating on parts with complex, three-dimensional geometries without sophisticated part rotation.

How to Apply This to Your Project

Understanding your primary objective is key to leveraging this technology effectively.

- If your primary focus is extreme durability: PVD is an excellent choice for applying hard, wear-resistant coatings to cutting tools, industrial components, and medical implants.

- If your primary focus is decorative or optical performance: The precise, atom-by-atom deposition allows for creating films that produce specific colors, reflectivity, or light-filtering properties.

- If your primary focus is corrosion resistance: A thin, dense vacuum-deposited layer can create an impermeable barrier that protects the underlying substrate from chemical attack.

Ultimately, vacuum coating is a versatile platform technology that transforms the surface properties of an object without altering its underlying structure.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Deposits thin, uniform material layers in a high-vacuum chamber |

| Core Benefit | Creates high-purity, high-performance coatings impossible in open air |

| Common Techniques | Thermal Evaporation, Physical Vapor Deposition (PVD) |

| Primary Applications | Durability (tools, implants), Decorative/optical finishes, Corrosion resistance |

| Main Advantage | Atom-by-atom deposition for precise, adherent thin films |

Ready to enhance your components with high-performance vacuum coatings?

KINTEK specializes in advanced lab equipment and consumables for vacuum coating processes, serving laboratories and manufacturers with precision solutions. Whether you need durable PVD coatings for industrial tools or precise optical films for research, our expertise ensures superior results.

Contact us today to discuss how our vacuum coating solutions can meet your specific project needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is the plasma CVD process? Achieve Low-Temperature Thin Film Deposition

- What are the advantages of plasma enhanced CVD? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings