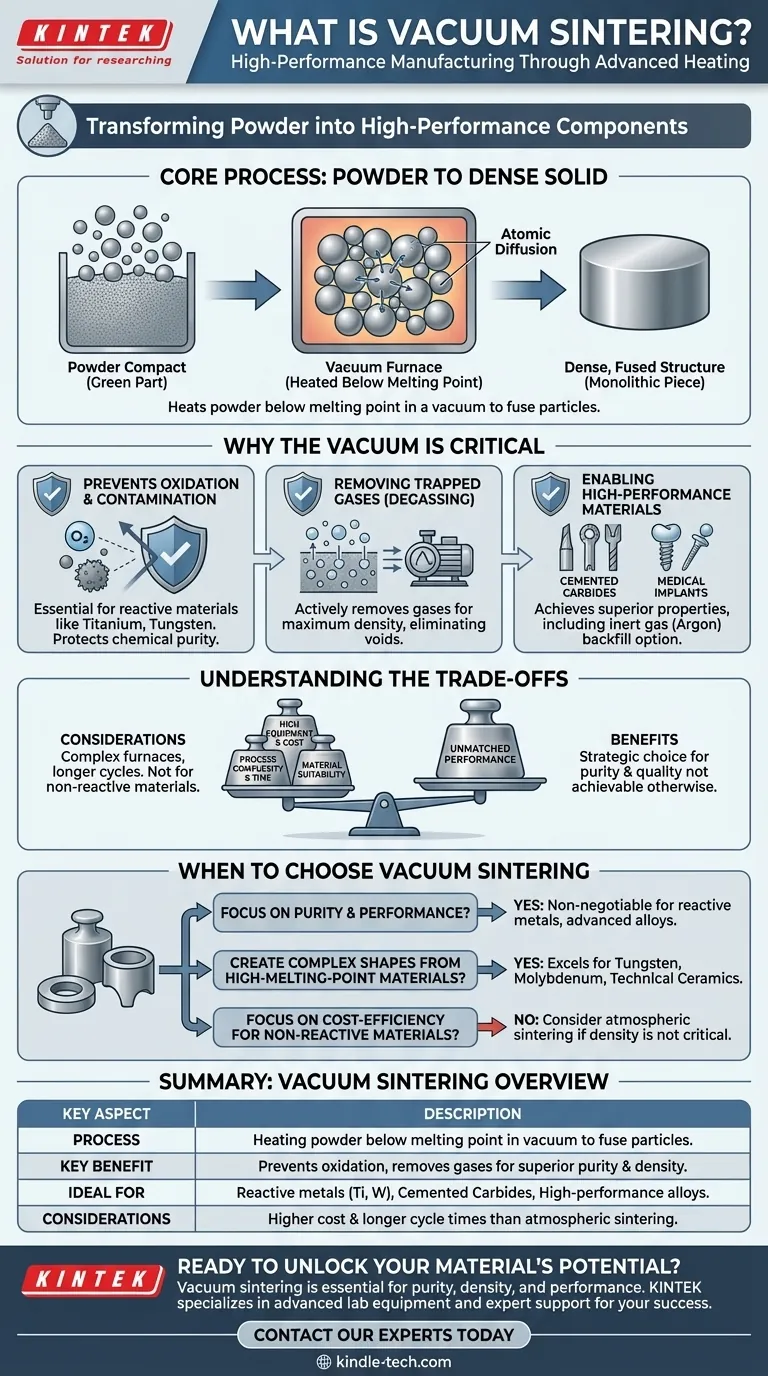

At its core, vacuum sintering is a high-performance manufacturing process that transforms powdered materials into a solid, dense object. It achieves this by heating the powder in a vacuum furnace to a temperature just below its melting point, causing the individual particles to fuse together through atomic diffusion. The vacuum environment is the key element, as it prevents chemical reactions like oxidation, resulting in a final product with exceptional purity and structural integrity.

The true value of vacuum sintering isn't just about creating a solid part; it's about precisely controlling the material's final properties. By removing air, the process eliminates contamination, enabling the creation of high-performance components that would be impossible to make through traditional melting and casting.

How Sintering Transforms Powder into a Solid

Sintering is a thermal process that has been used for centuries, from ancient pottery to modern metallurgy. Vacuum sintering is a highly advanced form of this fundamental technique.

The Starting Point: A Powder Compact

The process begins with a base material in powder form. This powder is often pressed or molded into a desired shape, known as a "green part." This initial compact is porous and mechanically weak, holding its shape but lacking the properties of a finished component.

The Role of Heat: Atomic Diffusion

The green part is placed in a furnace and heated. Crucially, the temperature is kept below the material's melting point. Instead of liquefying, the heat gives the atoms in the powder particles enough energy to move and migrate across the boundaries between them.

The Result: A Dense, Fused Structure

As atoms diffuse, the gaps and pores between the powder particles begin to close. The particles fuse together, creating strong inter-particle bonds and causing the entire component to shrink and densify. The result is a solid, monolithic piece with dramatically improved strength and durability.

Why the Vacuum is the Critical Component

Performing the sintering process in a vacuum is what separates this technique from more conventional methods. The controlled atmosphere is not an afterthought; it is fundamental to the outcome.

Preventing Oxidation and Contamination

Many advanced materials, especially metals like titanium or tungsten, are highly reactive with oxygen at high temperatures. Sintering in open air would cause them to oxidize instantly, forming a brittle, useless oxide layer. A vacuum removes the air, protecting the material and preserving its chemical purity.

Removing Trapped Gases (Degassing)

The powder compact inevitably contains trapped gases within its pores. The vacuum actively pulls these gases out of the part as it is heated. This "degassing" effect is critical for achieving maximum density and eliminating internal voids that could become failure points.

Enabling High-Performance Materials

The combination of preventing oxidation and removing trapped gases makes it possible to produce materials with superior properties. This is why vacuum sintering is essential for manufacturing items like cemented carbide cutting tools, high-purity medical implants, and specialized electronic components. In some cases, the furnace may be backfilled with an inert gas like argon to create a specific partial-pressure environment for even greater control.

Understanding the Trade-offs

While powerful, vacuum sintering is a specialized process with distinct considerations. It is not the right choice for every application.

Equipment and Cost

Vacuum furnaces are complex, high-capital equipment. The cost of purchasing, operating, and maintaining these systems makes vacuum sintering a more expensive process than sintering in a standard atmospheric furnace.

Process Complexity and Time

Achieving a high vacuum while precisely managing a multi-stage temperature profile requires sophisticated control systems and expertise. The entire cycle, including pump-down, heating, soaking, and cooling, can be significantly longer than other manufacturing methods.

Material Suitability

The primary driver for using a vacuum is to protect reactive materials or achieve the highest possible density. For materials that are not sensitive to oxygen, such as certain ceramics or iron-based powders, a simpler and less expensive atmospheric sintering process is often sufficient.

When to Choose Vacuum Sintering

Selecting the right manufacturing process depends entirely on your end goal. Use these guidelines to determine if vacuum sintering is the appropriate choice for your project.

- If your primary focus is material purity and performance: Vacuum sintering is non-negotiable for reactive metals or advanced alloys where even trace impurities from the atmosphere would compromise final strength and function.

- If your primary focus is creating complex shapes from high-melting-point materials: This process excels at producing near-net-shape parts from materials like tungsten, molybdenum, and technical ceramics that are difficult or impossible to melt and cast.

- If your primary focus is cost-efficiency for non-reactive materials: A simpler atmospheric sintering process or another manufacturing method may be more suitable if the material is stable in air and absolute maximum density is not a critical requirement.

Ultimately, selecting vacuum sintering is a strategic decision to achieve a level of material quality and performance that other processes cannot deliver.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Heating powder below its melting point in a vacuum to fuse particles. |

| Key Benefit | Prevents oxidation and removes gases for superior material purity and density. |

| Ideal For | Reactive metals (titanium, tungsten), cemented carbides, high-performance alloys. |

| Considerations | Higher equipment cost and longer cycle times than atmospheric sintering. |

Ready to unlock the full potential of your materials?

Vacuum sintering is essential for creating components where purity, density, and performance are non-negotiable. At KINTEK, we specialize in providing the advanced lab equipment and expert support you need to master this critical process.

Whether you're developing medical implants, cutting tools, or specialized electronic components, our solutions are designed for your laboratory's success.

Contact our experts today to discuss how KINTEK can enhance your sintering capabilities and help you achieve breakthrough results.

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- Why would you braze instead of solder? For Superior Joint Strength and High-Temperature Performance

- What is the sintering time? A Critical Process Variable for Material Density and Strength

- Can you heat something in a vacuum chamber? Master Precise Thermal Processing in Airless Environments

- How is heating done in sintering operation? Master the Core Methods for Dense, Strong Parts

- What is sintering reaction? Transform Powders into Dense Solids Without Melting