Vacuum tempering is a heat treatment process used to increase the toughness and reduce the brittleness of a previously hardened metal part. The entire process—heating the part to a specific temperature, holding it for a set time, and cooling it—is conducted inside a sealed chamber from which the air has been removed, creating a vacuum. This controlled, oxygen-free environment is the key feature that distinguishes it from conventional tempering.

The primary purpose of using a vacuum for tempering is not the vacuum itself, but the pristine, oxygen-free environment it creates. This prevents surface oxidation and discoloration, ensuring the final component meets exact mechanical specifications with a clean, bright finish.

The Core Objective: Balancing Hardness and Toughness

To understand vacuum tempering, it's essential to first grasp the fundamental trade-off it manages in metallurgy.

The Problem with Hardening

When steel is hardened (typically through a process called quenching), its internal crystal structure changes, making it extremely hard. However, this process also introduces significant internal stress, leaving the metal very brittle, similar to glass. A fully hardened part might shatter if dropped or subjected to impact.

How Tempering Provides the Solution

Tempering is the critical subsequent step that relieves this internal stress. The part is reheated to a temperature well below its hardening point, which allows the internal structure to relax and reform slightly.

This carefully controlled heating cycle reduces brittleness and imparts toughness—the ability to absorb energy and deform without fracturing.

The Result: Tempered Martensite

The goal of tempering is to transform the brittle internal structure into a refined microstructure known as tempered martensite. This structure possesses the ideal combination of high hardness and sufficient toughness for demanding applications.

Why Perform Tempering in a Vacuum?

Choosing to temper in a vacuum is a decision to prioritize purity and surface quality. The vacuum environment provides several distinct advantages over tempering in a conventional furnace with a normal atmosphere.

To Eliminate Surface Oxidation

At elevated temperatures, the oxygen in the air reacts instantly with a metal's surface, forming a dark, flaky layer of oxide scale. A vacuum removes virtually all the oxygen, completely preventing this reaction. Parts emerge from the furnace with a bright, clean surface, eliminating the need for secondary cleaning operations like sandblasting or chemical baths.

To Ensure Absolute Purity

A vacuum environment is free from atmospheric contaminants like oxygen, nitrogen, and water vapor. This prevents these elements from reacting with the metal's surface, which is critical for sensitive alloys used in the aerospace, medical, and electronics industries.

To Improve Part Performance

By preventing surface reactions, vacuum tempering ensures the metallurgical properties of the surface are identical to the core of the material. This can lead to improved performance characteristics, including enhanced corrosion resistance and predictable wear life.

To Achieve Precise Temperature Uniformity

Vacuum furnaces provide an extremely stable and uniform heating environment. This precise control ensures that every part in a batch, regardless of its position, receives the exact same thermal treatment, leading to highly consistent and repeatable mechanical properties.

Understanding the Trade-offs

While the benefits are significant, vacuum tempering is not the default choice for every application due to several practical considerations.

Higher Equipment and Operational Costs

Vacuum furnaces are significantly more complex and expensive to purchase and maintain than conventional atmosphere furnaces. The process of pulling a vacuum for each cycle also consumes more energy and time.

Slower Overall Cycle Times

While the heating itself can be efficient, the need to pump down the chamber to create the vacuum adds time to the beginning of every cycle. For high-volume, low-cost parts, this can be a production bottleneck.

Not Always Necessary

For many general-purpose components, a thin layer of surface oxide is perfectly acceptable or is easily removed. In these cases, the added expense and complexity of vacuum processing are simply not justified.

Making the Right Choice for Your Goal

Selecting the appropriate tempering method depends entirely on the requirements of the final component.

- If your primary focus is maximum performance and a pristine finish: Vacuum tempering is the superior choice, especially for aerospace, medical, or high-performance tooling where surface integrity is non-negotiable.

- If your primary focus is general-purpose toughness and cost-efficiency: Conventional atmosphere tempering is often sufficient, provided a slight surface discoloration or the need for a secondary cleaning process is acceptable.

- If your part must have zero surface contamination: The vacuum process is the only way to guarantee a component free from the oxides and nitrides that can form in a standard atmosphere.

Ultimately, choosing vacuum tempering is a decision to prioritize metallurgical perfection and surface purity over lower operational costs.

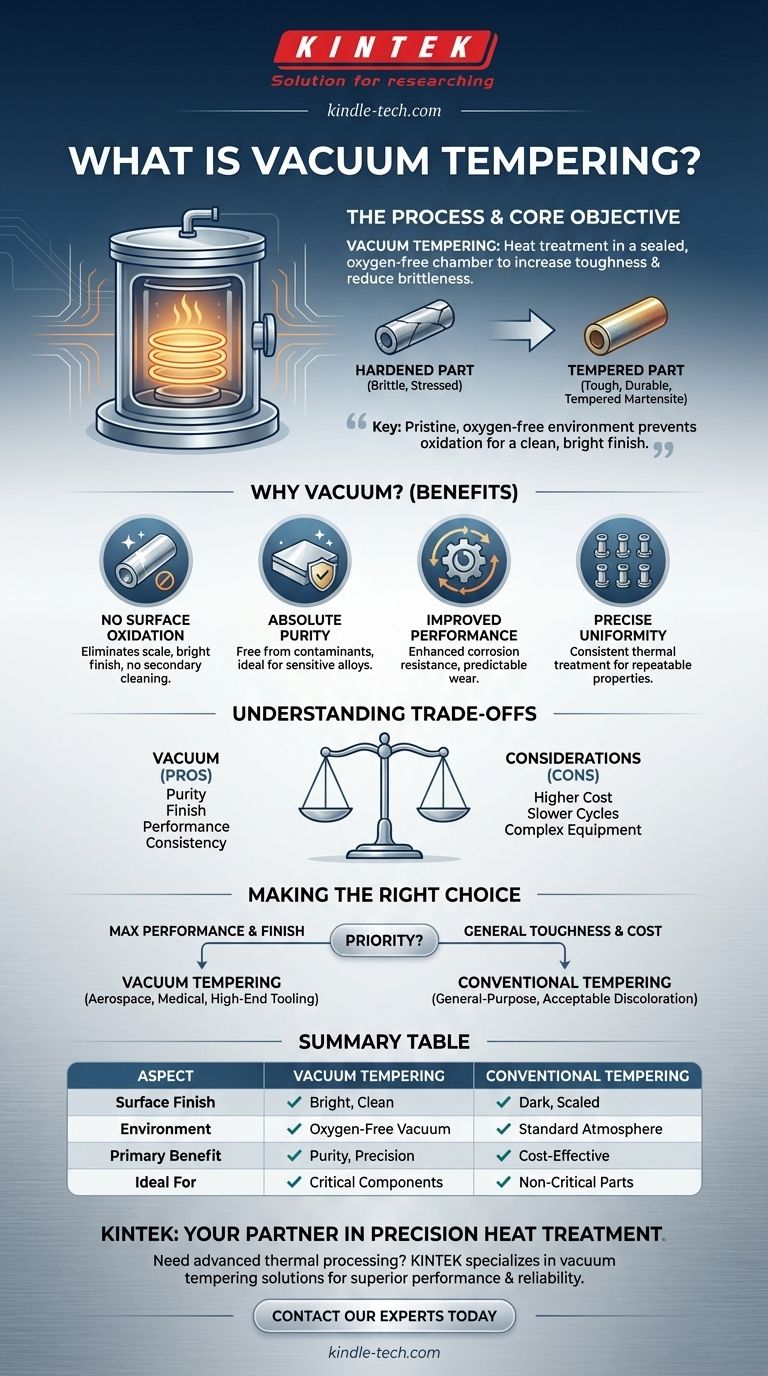

Summary Table:

| Aspect | Vacuum Tempering | Conventional Tempering |

|---|---|---|

| Surface Finish | Bright, clean, no oxidation | Dark, scaled surface (oxidation) |

| Environment | Oxygen-free vacuum | Standard atmosphere (air) |

| Primary Benefit | Purity, no contamination, precise properties | Cost-effective for non-critical parts |

| Ideal For | Aerospace, medical, high-performance tooling | General-purpose components |

Need precision heat treatment for your critical components?

At KINTEK, we specialize in advanced thermal processing solutions, including vacuum tempering. Our state-of-the-art vacuum furnaces ensure your metal parts achieve the perfect balance of hardness and toughness with a pristine, oxide-free finish—eliminating the need for secondary cleaning and guaranteeing superior performance.

Whether you're in aerospace, medical device manufacturing, or high-performance tooling, KINTEK's expertise in lab equipment and consumables is your partner for quality and reliability.

Contact our experts today to discuss how vacuum tempering can enhance your product's performance and longevity.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Hot Press Furnace Heated Vacuum Press Machine Tube Furnace

People Also Ask

- Is heat Cannot travel in a vacuum True or false? Discover How Heat Crosses the Void of Space

- What are the advantages of a vacuum furnace? Achieve Superior Purity and Control in Heat Treatment

- How does a vacuum heat treatment work? Achieve Superior Material Properties in a Pristine Environment

- Where are vacuum furnaces used? Essential for High-Purity Heat Treatment in Critical Industries

- What is a vacuum furnace? The Ultimate Guide to Contamination-Free Thermal Processing