In metallurgy, VIM stands for Vacuum Induction Melting. It is a sophisticated furnace technology used to melt and refine metals and alloys within a high-vacuum environment. The process relies on electromagnetic induction to generate heat directly within the metallic charge, ensuring a clean melt free from the atmospheric contamination that plagues conventional air-melting techniques.

The core purpose of VIM is not just to melt metal, but to purify it. By operating in a vacuum, the process removes dissolved gases and volatile impurities, enabling the production of extremely clean, high-performance alloys with precise chemical compositions.

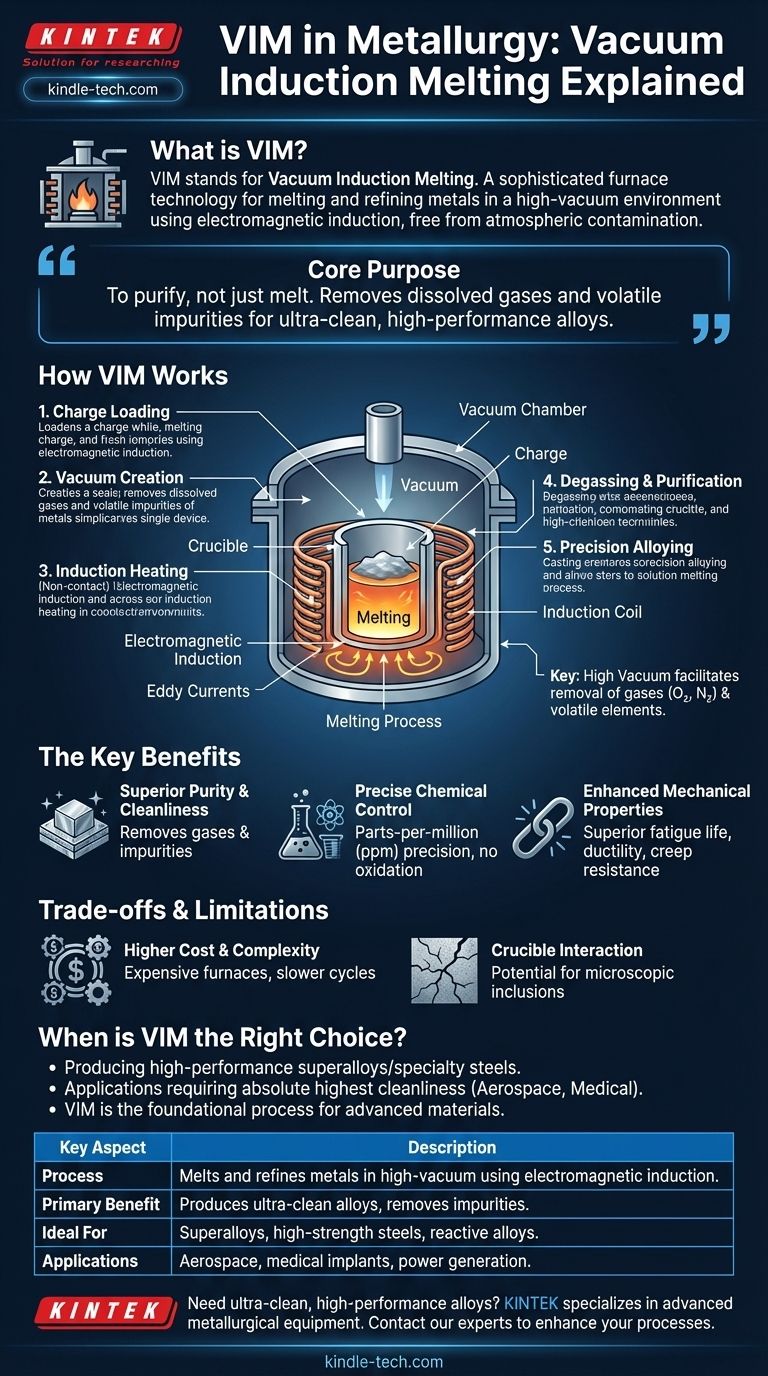

How Vacuum Induction Melting Works

Vacuum Induction Melting is a batch process performed inside a sealed, water-cooled steel chamber. The precision of the system is what sets it apart from other melting methods.

The Core Components

A VIM furnace consists of three primary parts: a vacuum chamber to contain the environment, a crucible (typically ceramic) to hold the metal, and a copper induction coil that surrounds the crucible but does not touch it.

The Melting Process

The process begins by loading solid raw materials (the "charge") into the crucible and sealing the chamber. Powerful pumps then create a deep vacuum, removing the air. An alternating electric current is passed through the induction coil, which generates a powerful, fluctuating magnetic field. This field induces eddy currents within the metallic charge, causing it to heat up rapidly and melt without any direct contact from a heat source.

The Purification Advantage

The high vacuum is the key to VIM's effectiveness. As the metal melts, the vacuum environment facilitates the removal of dissolved gases like oxygen and nitrogen, a process known as degassing. It also causes undesirable trace elements with high vapor pressures (like lead, bismuth, and cadmium) to boil off and be removed by the vacuum system.

Precision Alloying and Casting

Once the base metal is molten and purified, precise amounts of other elements can be added to create a specific alloy. Because there is no oxygen in the chamber, highly reactive elements like aluminum, titanium, and niobium can be added without being lost to oxidation. The final molten alloy is then poured into molds, often within the vacuum chamber itself, to form solid ingots.

The Key Benefits of the VIM Process

The highly controlled VIM environment delivers tangible improvements to the final material, making it essential for critical applications.

Superior Purity and Cleanliness

By removing dissolved gases and non-metallic impurities, VIM produces exceptionally "clean" metal. This cleanliness is directly linked to improved performance, particularly in applications where microscopic defects can lead to catastrophic failure.

Precise Chemical Control

The vacuum prevents unintended reactions, allowing metallurgists to control the alloy's final composition with extreme precision, often down to the parts-per-million (ppm) level. This guarantees consistent material properties from one batch to the next.

Enhanced Mechanical Properties

Alloys produced via VIM exhibit superior fatigue life, ductility, creep resistance, and fracture toughness. This is why VIM is the standard primary melting process for nickel-based superalloys, high-strength steels, and specialty alloys used in aerospace engines, power generation turbines, and medical implants.

Understanding the Trade-offs and Limitations

While powerful, VIM is not the universal solution for all metal production. Understanding its context is crucial for making informed engineering decisions.

Higher Cost and Complexity

VIM furnaces are complex, expensive to build and operate, and have slower production cycles compared to air-melting methods like the Electric Arc Furnace (EAF). This makes the process uneconomical for producing common grades of steel or aluminum.

The Role of the Crucible

Although minimal, there can be a slight reaction between the highly reactive molten metal and the ceramic crucible lining. This can introduce microscopic ceramic inclusions into the melt, which can be detrimental in the most demanding applications.

Not Always the Final Step

Because of the potential for crucible inclusions, VIM is often used as the first step in a two-stage process for creating the highest-purity materials. The VIM-produced ingot serves as a superior electrode that is then remelted in a secondary process like Vacuum Arc Remelting (VAR) or Electroslag Remelting (ESR) to further refine the structure and remove any remaining impurities.

When is VIM the Right Choice?

Choosing a melting process depends entirely on the required performance and cost constraints of the final component.

- If your primary focus is producing high-performance superalloys or specialty steels: VIM is the essential starting point for achieving the necessary purity and precise chemical control.

- If your application requires the absolute highest level of cleanliness and structural integrity (e.g., rotating aerospace parts): Use VIM as the primary melt, followed by a secondary remelting process like VAR to create a VIM-VAR alloy.

- If you are producing standard-grade alloys where cost is the main driver: Conventional air-melting processes are far more economical and perfectly suitable for the application.

Ultimately, Vacuum Induction Melting is the foundational process for creating the world's most advanced and reliable metallic materials.

Summary Table:

| Key Aspect | Description |

|---|---|

| Process | Melts and refines metals in a high-vacuum environment using electromagnetic induction. |

| Primary Benefit | Produces ultra-clean alloys by removing dissolved gases and volatile impurities. |

| Ideal For | Nickel-based superalloys, high-strength steels, and reactive alloys requiring precise chemistry. |

| Common Applications | Aerospace turbine blades, medical implants, power generation components. |

Need to produce ultra-clean, high-performance alloys? KINTEK specializes in advanced laboratory equipment and consumables for metallurgical research and production. Our expertise in vacuum furnace technology can help you achieve the precise chemical control and superior material properties required for your most demanding applications. Contact our experts today to discuss how our solutions can enhance your metallurgical processes.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the technical advantages of using an induction melting furnace? Precision for Nickel-Based Superalloys

- Does induction heating work on graphite? Achieve High-Temperature Precision and Efficiency

- What is the cost of an induction furnace? A Guide to Budgeting for Your Melting System

- What are different types of induction furnaces? Coreless vs. Channel Furnace Explained

- What frequency is required for induction heating? Match Frequency to Your Heating Depth

- What is the advantage of induction furnace? Achieve Clean, Precise, and Efficient Metal Melting

- What is the difference between blast furnace and induction furnace? Choosing the Right Metal Melting Solution

- What is the temperature of induction heating process? Unlock Precise Control from Gentle Warming to 1800°C+