The machine used for pyrolysis is called a pyrolysis reactor. This is not a single, standardized piece of equipment but rather a category of highly specialized industrial systems. The specific type of reactor chosen depends entirely on the material being processed—known as the feedstock—and the desired end products, whether that is bio-oil, biochar, or synthesis gas (syngas).

While many machines can be called a "pyrolysis reactor," the critical insight is that each design represents a different engineering solution to a specific problem. Selecting the right reactor type is the most important decision, as it dictates the efficiency, scale, and output of the entire process.

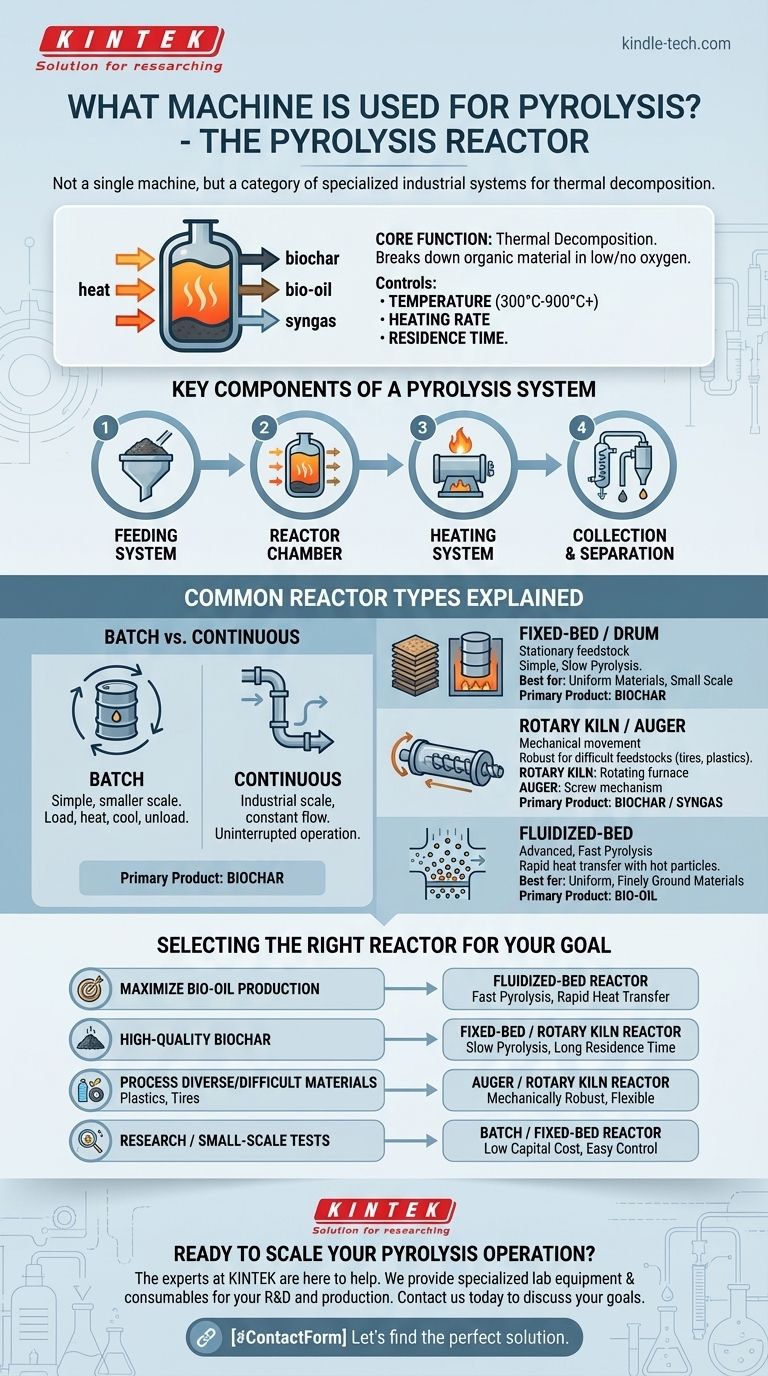

What is a Pyrolysis Reactor?

A pyrolysis reactor is the core component of a system designed to thermally decompose organic material in an environment with little to no oxygen. This process breaks down complex molecules into simpler, more valuable substances.

The Core Function: Thermal Decomposition

At its heart, a pyrolysis reactor is a vessel that can be heated to very high temperatures (typically 300°C to 900°C or higher) while keeping oxygen out. Preventing combustion is what differentiates pyrolysis from simple burning (incineration).

The reactor's job is to precisely control three key variables: temperature, heating rate, and the amount of time the material spends inside, known as residence time.

Key Components of a Pyrolysis System

A complete pyrolysis plant includes more than just the reactor. The main components are:

- Feeding System: Introduces the feedstock (e.g., plastic, biomass, tires) into the reactor.

- Reactor Chamber: The heated, oxygen-free vessel where pyrolysis occurs.

- Heating System: Provides the energy needed to drive the reaction.

- Collection & Separation System: Captures the outputs and separates them into solid (biochar), liquid (bio-oil), and gas (syngas) streams.

Common Types of Pyrolysis Reactors Explained

The term "pyrolysis reactor" encompasses a wide range of designs, each with unique advantages. They are often categorized by how the feedstock is handled and heated inside the chamber.

Batch vs. Continuous Reactors

This is the most fundamental distinction. A batch reactor is loaded with feedstock, sealed, heated for the reaction, and then cooled down to remove the products. It is simple and common for smaller-scale operations.

A continuous reactor is designed for industrial scale, with a constant flow of feedstock entering and products leaving the system, allowing for uninterrupted operation.

Fixed-Bed and Drum Reactors

In a fixed-bed reactor, the feedstock remains stationary in a pile or "bed" as it is heated. This is one of the simplest designs, often used in batch or semi-batch mode.

A drum reactor is a variation where the entire sealed drum containing the feedstock is placed into a larger furnace. Both are examples of slow pyrolysis, which favors the production of biochar.

Rotary Kiln and Auger Reactors

These reactors use mechanical movement to transport material. A rotary kiln is a large, rotating cylindrical furnace set at a slight incline. As it rotates, the feedstock tumbles and mixes, ensuring even heating as it moves from the entrance to the exit.

An auger reactor (or screw reactor) uses a large screw mechanism to push material through a heated tube. Both designs are robust and excellent at handling inconsistent or difficult-to-manage feedstocks like shredded plastics or sludge.

Fluidized-Bed Reactors

This is a more advanced design for continuous, fast pyrolysis. In a fluidized-bed reactor, a hot gas is forced up through a bed of fine particles (like sand). When the feedstock is introduced, it is rapidly mixed and heated by the turbulent, "fluid-like" motion of the hot particles.

This process provides extremely efficient heat transfer, making it ideal for maximizing the production of liquid bio-oil.

Understanding the Trade-offs

No single reactor design is universally superior. The choice involves a series of critical engineering trade-offs based on the project's goals and constraints.

Feedstock Flexibility vs. Preparation

Mechanically agitated reactors like rotary kilns and augers are highly flexible and can process larger, non-uniform materials. In contrast, fluidized-bed reactors demand a very uniform, finely ground feedstock to operate correctly, which adds cost and complexity to material preparation.

Heat Transfer and Product Output

The speed of heating directly influences the final products.

- Slow Pyrolysis (Fixed-Bed, Drum): Slower heating rates and long residence times maximize the yield of solid biochar.

- Fast Pyrolysis (Fluidized-Bed, Ablative): Extremely rapid heating rates maximize the yield of liquid bio-oil.

Scalability and Operating Cost

Batch reactors are relatively simple and have a lower initial cost, making them suitable for research or small-scale specialty production. Continuous reactors like rotary kilns and fluidized beds are more complex and expensive to build but offer economies of scale and lower operating costs per ton for large, industrial applications.

Selecting the Right Reactor for Your Goal

The ideal reactor is determined by your specific objective and the material you intend to process. Your choice must align with your desired primary product.

- If your primary focus is maximizing bio-oil production: You need a fast pyrolysis reactor, such as a fluidized-bed or ablative type, for its rapid heat transfer.

- If your primary focus is producing high-quality biochar: A slow pyrolysis reactor, like a fixed-bed or rotary kiln, is the superior choice for its longer residence times.

- If you are processing diverse or difficult materials like mixed plastics or tires: A mechanically robust system like an auger or rotary kiln provides the necessary feedstock flexibility.

- If you are conducting research or small-scale tests: A simple batch or fixed-bed reactor offers the lowest capital cost and easiest operational control.

Ultimately, understanding these reactor types empowers you to move beyond the simple question of "what machine" and toward selecting the precise tool for your specific application.

Summary Table:

| Reactor Type | Best For Feedstock | Primary Product | Key Characteristic |

|---|---|---|---|

| Fixed-Bed / Drum | Uniform materials, small scale | Biochar | Simple, slow pyrolysis, batch operation |

| Rotary Kiln | Diverse, bulky materials (tires, plastics) | Biochar / Syngas | Robust, handles inconsistent feedstocks |

| Auger (Screw) | Difficult materials (sludge, mixed plastics) | Bio-oil / Biochar | Good heat transfer, continuous operation |

| Fluidized-Bed | Uniform, finely ground materials | Bio-oil | Fast pyrolysis, high efficiency, continuous |

Ready to Scale Your Pyrolysis Operation?

Selecting the right reactor is the most critical step for efficiency and profitability. The experts at KINTEK are here to help you navigate these complex choices.

We provide specialized lab equipment and consumables to support your pyrolysis R&D and production, ensuring you have the right tools for success.

Contact us today via the form below to discuss your specific feedstock and goals. Let's find the perfect pyrolysis solution for your laboratory or facility.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What type of samples can be characterized with IR spectroscopy? Analyze Solids, Liquids, and Gases

- Why is the metal melting temperature important? The Key to Manufacturing & Performance

- Why is deposition technology an amazing scientific advancement? Unlock Atomic-Level Material Engineering

- How do you heat treat metal to make it stronger? Master the Process of Hardening, Quenching, and Tempering

- What are the material advantages of using an agate mortar and pestle? Ensure Pure Sulfide Electrolyte Processing

- Which glass materials are used in sintering? Key Materials and Applications for Precision Manufacturing

- What is the microwave pyrolysis method? A Faster, More Efficient Way to Convert Waste into Value

- What are the processes that need to be done after completing the sintering stage? Master the Critical Post-Sintering Steps