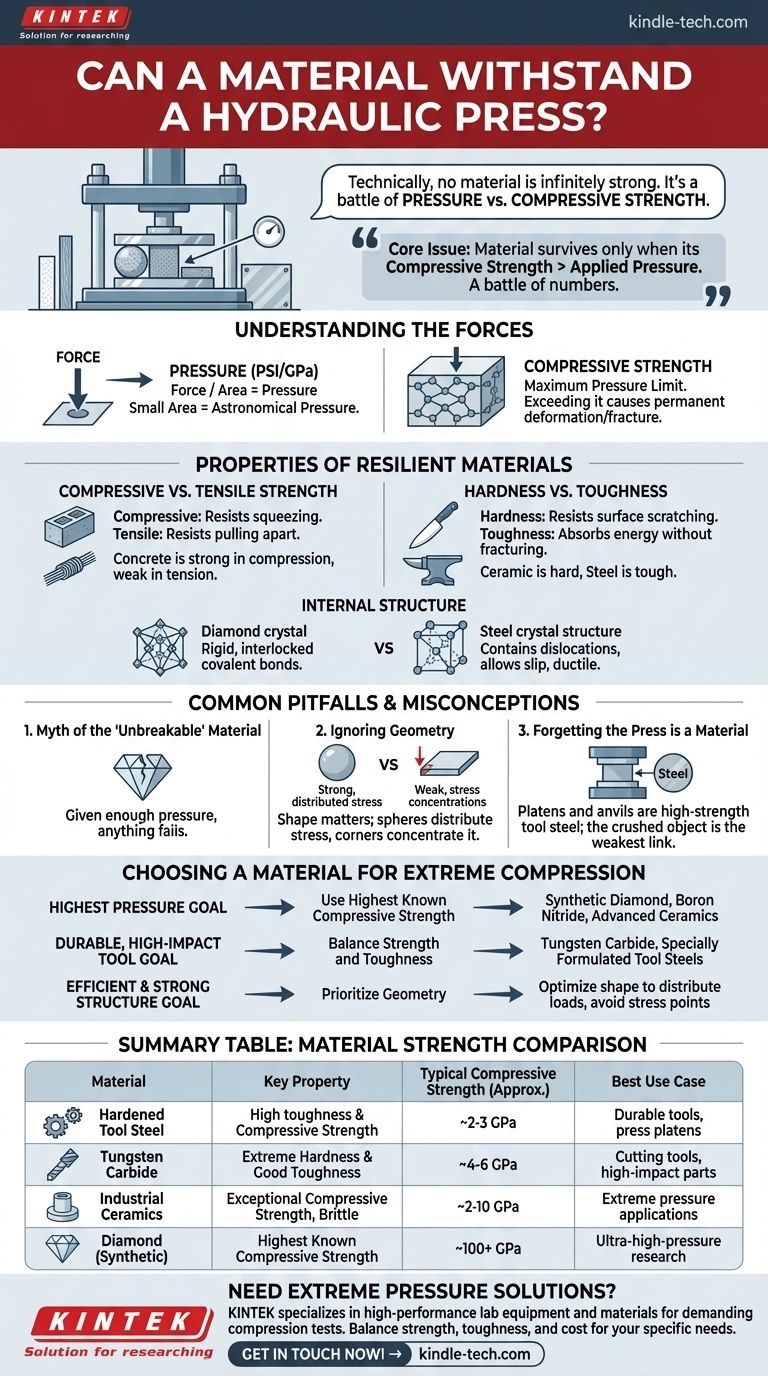

Technically, no material is infinitely strong. The ability of an object to withstand a hydraulic press is a direct contest between the pressure the press can exert and the material's inherent compressive strength. For common industrial presses, materials like hardened tool steel, tungsten carbide, and certain industrial ceramics can often resist being crushed.

The core issue is not finding an "unbreakable" material, but understanding that a material survives only when its compressive strength is greater than the pressure applied to it. It is a battle of numbers, where a sufficiently powerful press can theoretically destroy any material.

Understanding the Forces at Play

A hydraulic press doesn't create force out of thin air. It uses a principle of fluid dynamics to multiply a small input force into an immense output force, which is then concentrated onto a small surface area.

The Key Metric: Pressure

The term you need to focus on is pressure, often measured in pounds per square inch (PSI) or gigapascals (GPa). A press might be rated for 100 tons of force, but that force is meaningless without knowing the area over which it is applied.

A 100-ton force concentrated on a tiny point generates astronomical pressure, while the same force spread over a large plate might be manageable.

The Opposing Force: Compressive Strength

Every material has a compressive strength, which is the maximum pressure it can withstand before it begins to deform permanently or fracture.

When a material is placed in a press, you are directly pitting the press's generated pressure against the material's compressive strength. If the press's pressure wins, the material fails.

The Properties of a Resilient Material

To "win" against a press, a material needs more than just brute strength. The internal structure and other properties are critical.

Compressive vs. Tensile Strength

Compressive strength (resisting being squeezed) is very different from tensile strength (resisting being pulled apart). Concrete, for example, has excellent compressive strength but is very weak under tension.

Materials that excel under compression often have highly ordered, tightly packed atomic structures that resist being pushed closer together.

Hardness vs. Toughness

These two terms are often confused. Hardness is a material's ability to resist surface scratching and indentation. Toughness is its ability to absorb energy and deform without fracturing.

A ceramic knife is extremely hard but not tough; it will shatter if you drop it. A steel anvil is tough, able to absorb the impact of a hammer blow, but less hard than the ceramic. For a press, you need high compressive strength, which is often, but not always, found in very hard materials.

The Role of Internal Structure

Materials like diamonds and ceramics derive their incredible compressive strength from their rigid, interlocked crystal lattices. The covalent bonds in a diamond's structure are exceptionally strong and uniformly arranged, making it incredibly difficult to compress.

Metals like steel have a crystalline structure, but it contains dislocations that allow the atoms to slip past one another, which is why steel bends before it breaks. This makes it tough, but ultimately gives it a lower compressive strength than top-tier ceramics.

Common Pitfalls and Misconceptions

Understanding what won't work is as important as understanding what will. It's easy to fall for common assumptions about strength.

The Myth of the "Unbreakable" Material

There is no such thing as an indestructible material. Given a large enough hydraulic press, anything can be crushed. Even a diamond will fail when the applied pressure exceeds the strength of its atomic bonds. The question is always a matter of scale.

Ignoring the Importance of Geometry

A sphere is one of the strongest shapes for resisting uniform external pressure because it distributes the stress evenly across its entire surface.

A flat plate made of the same material will fail at a much lower force because the stress is not distributed as efficiently. A part with sharp internal corners will create stress concentrations, leading to failure even if the overall material is strong.

Forgetting the Press Itself Is a Material

The platens (the flat surfaces) and anvils used in a hydraulic press are themselves made of materials with exceptionally high compressive strength, typically high-grade, heat-treated tool steel. In any test, the object being crushed is almost always the weakest link in the system by design.

How to Choose a Material for Extreme Compression

Your choice depends entirely on the specific goal, balancing performance, cost, and practicality.

- If your primary focus is resisting the absolute highest pressure: You must use materials with the highest known compressive strength, like synthetic diamonds, boron nitride, or advanced ceramics.

- If your primary focus is engineering a durable, high-impact tool: You need a balance of high compressive strength and toughness, making tungsten carbide or specially formulated tool steels the superior choice.

- If your primary focus is creating an efficient and strong structure: Prioritize the geometry of the object to eliminate stress points and distribute loads evenly, as a superior design can outperform a stronger but poorly shaped material.

Ultimately, defeating a hydraulic press is a problem of engineering and physics, not a quest for a mythical substance.

Summary Table:

| Material | Key Property | Typical Compressive Strength (Approx.) | Best Use Case |

|---|---|---|---|

| Hardened Tool Steel | High toughness & compressive strength | ~2-3 GPa | Durable tools, press platens |

| Tungsten Carbide | Extreme hardness & good toughness | ~4-6 GPa | Cutting tools, high-impact parts |

| Industrial Ceramics | Exceptional compressive strength, brittle | ~2-10 GPa | Extreme pressure applications |

| Diamond (Synthetic) | Highest known compressive strength | ~100+ GPa | Ultra-high-pressure research |

Need a material that can handle extreme pressure in your lab? KINTEK specializes in high-performance lab equipment and consumables, including materials and tools designed for demanding compression tests. Our expertise ensures you get the right solution for your specific application, balancing strength, toughness, and cost. Contact us today to discuss how we can support your laboratory's needs—Get in touch now!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Laboratory Manual Hydraulic Pellet Press for Lab Use

- Laboratory Hydraulic Press Lab Pellet Press for Button Battery

People Also Ask

- How does the high pressure provided by a laboratory hydraulic press impact the formation of solid-state battery cells?

- How do laboratory hydraulic presses and specialized fixtures ensure the accuracy of electrochemical testing? (Expert Guide)

- What converts hydraulic pressure into mechanical force? Unlock the Power of Hydraulic Actuators

- What are the safety hazards of hydraulic presses? Mitigate Crush, Injection, and Ejection Risks

- What steel is used for a hydraulic press? Choosing the Right Materials for High-Stress Performance

- What affects the speed of a hydraulic motor? Master the balance of flow rate and displacement

- How do desired diamond color and size influence the HPHT process? Balancing Growth Rates and Mechanical Stability

- What is metal forming with a hydraulic press? Harnessing Immense Force for Precision Shaping