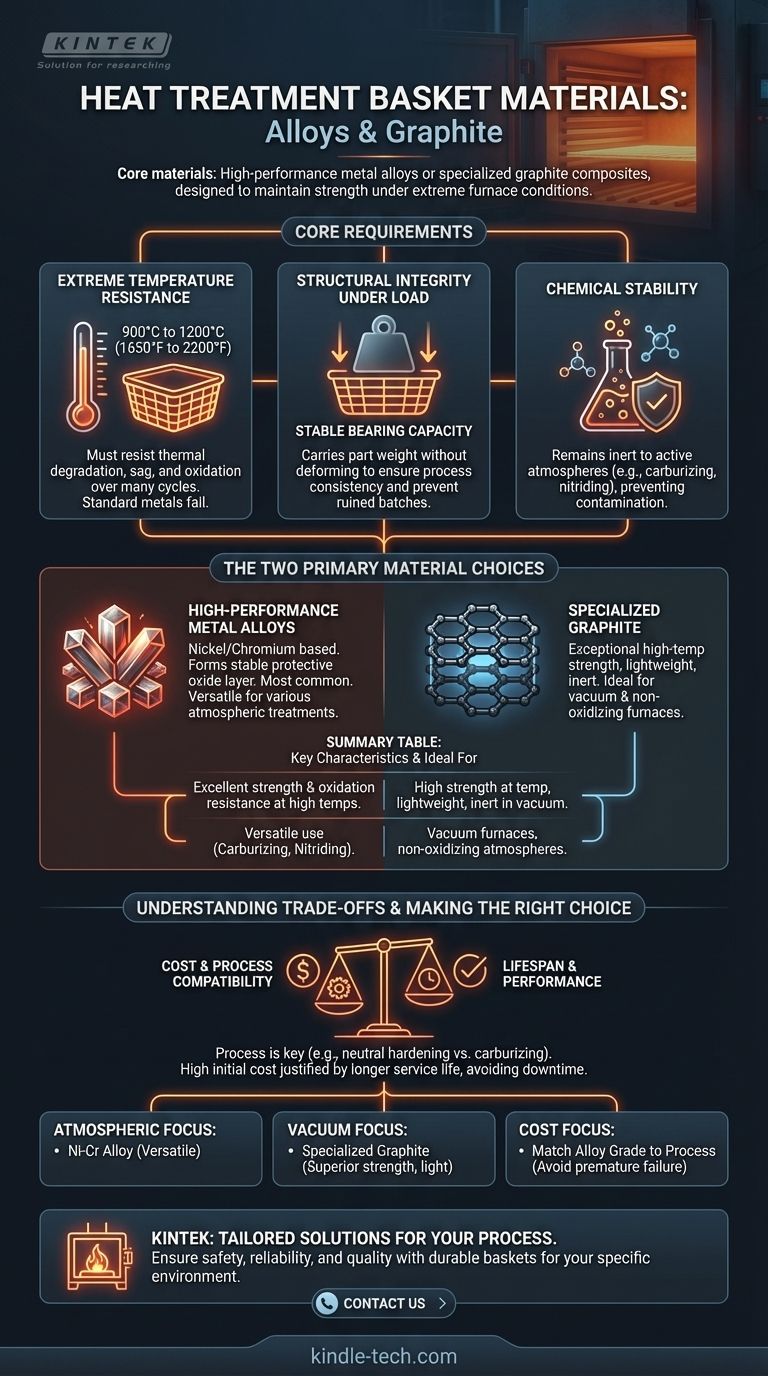

At its core, a heat treatment basket is made from one of two classes of materials: high-performance metal alloys or specialized graphite composites. These materials are chosen specifically for their unique ability to maintain their strength and shape under the extreme conditions of a heat treatment furnace.

The selection of a basket material is not arbitrary; it is a critical engineering decision dictated by the need for a material that can withstand punishing temperatures and chemically active environments without failing or contaminating the parts being treated.

The Core Requirements for Basket Materials

To understand why only specific materials are used, we must first understand the hostile environment inside a heat treatment furnace. The basket isn't just a container; it's a piece of high-performance tooling.

Extreme Temperature Resistance

The primary challenge is temperature. Baskets must operate consistently in environments ranging from 900°C to 1200°C (1650°F to 2200°F).

Standard metals like carbon steel would lose all structural integrity, sag, and oxidize rapidly at these temperatures. The chosen material must resist this thermal degradation over many cycles.

Structural Integrity Under Load

A basket must carry the weight of the parts it holds without deforming. This property, known as stable bearing capacity, is essential for process consistency and safety.

If a basket warps or sags, it can cause parts to be heated unevenly or even drop, leading to ruined batches and potential furnace damage.

Chemical Stability

Many heat treatment processes, such as carburizing or nitriding, use chemically active atmospheres to alter the surface of the parts.

The basket material must remain inert and not react with these gases. A reactive basket could degrade quickly or, worse, interfere with the chemical composition of the parts themselves.

The Two Primary Material Choices

Given these stringent requirements, the industry relies on two main categories of materials.

High-Performance Metal Alloys

This is the most common category. These are not standard steels but highly specialized alloys, often based on nickel or chromium.

These alloys are engineered to form a stable, protective oxide layer at high temperatures, which prevents further degradation and allows them to maintain their strength.

Specialized Graphite

Graphite is an excellent choice for its exceptional strength at high temperatures; in fact, it often gets stronger as it gets hotter, up to a point.

It is also significantly lighter than metal alloys, which can be an advantage in handling and energy consumption. However, its use is typically reserved for specific applications, such as vacuum furnaces, where it will not oxidize.

Understanding the Trade-offs

Choosing between materials involves balancing performance, cost, and process compatibility. No single material is perfect for every application.

Process vs. Material Compatibility

A basket made of a certain metal alloy might be perfect for neutral hardening but could fail prematurely in a high-carbon carburizing atmosphere.

The specific heat treatment process—whether it's annealing, quenching, tempering, or carburizing—is the single most important factor in selecting the right basket material.

Cost vs. Lifespan

High-performance alloys and graphite are significantly more expensive than standard metals. However, this initial investment is often justified by a much longer service life.

Using a cheaper, less suitable material inevitably leads to more frequent replacement, costly downtime, and a higher risk of catastrophic failure during a cycle.

Making the Right Choice for Your Goal

The optimal material is always tied to the specific application and operational priorities.

- If your primary focus is robust performance across a wide range of atmospheric treatments: A carefully selected nickel-chromium metal alloy is typically the most versatile and reliable choice.

- If your primary focus is processing in a vacuum or a non-oxidizing atmosphere: Specialized graphite can offer superior high-temperature strength and lower weight.

- If your primary focus is managing operational costs: The key is to match the grade of the metal alloy precisely to the demands of the process to avoid both premature failure and over-engineering.

Ultimately, selecting the correct basket material is fundamental to ensuring the safety, reliability, and quality of your heat treatment operations.

Summary Table:

| Material Type | Key Characteristics | Ideal For |

|---|---|---|

| High-Performance Metal Alloys | Excellent strength & oxidation resistance at high temps (900-1200°C) | Versatile use in various atmospheric treatments (carburizing, nitriding) |

| Specialized Graphite | High strength at temperature, lightweight, inert in vacuum | Vacuum furnaces, non-oxidizing atmospheres |

Ensure the safety and quality of your heat treatment process. Selecting the correct basket material is critical for preventing contamination, avoiding costly downtime, and achieving consistent results. At KINTEK, we specialize in high-performance lab equipment and consumables, including durable heat treatment baskets tailored to your specific furnace environment and process needs—whether you require robust metal alloys or specialized graphite.

Let our experts help you optimize your workflow. Contact us today to discuss your requirements and find the perfect solution for your laboratory.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What are the acceptance criteria for muffle furnace? Ensure Safety, Performance & Success

- What temperature does molten steel melt? Understand the Melting Range, Not a Single Point

- What is the function of a muffle furnace? Achieve Pure, Contamination-Free Heating

- How is a muffle furnace used for sample digestion? A Guide to Dry Ashing for Accurate Analysis

- What are the uses of furnace in chemistry laboratory? Unlock High-Temperature Material Synthesis and Analysis