Crucibles are engineered from a range of specialized materials, including clay-graphite, silicon carbide, platinum, and zirconium. The specific material used is determined entirely by the temperature and chemical reactivity of the substance it is designed to hold.

The selection of a crucible material is not arbitrary; it is a critical decision based on a trade-off between thermal resistance, chemical inertness, and cost. The right choice depends entirely on whether the goal is melting large volumes of metal or performing a precise chemical analysis.

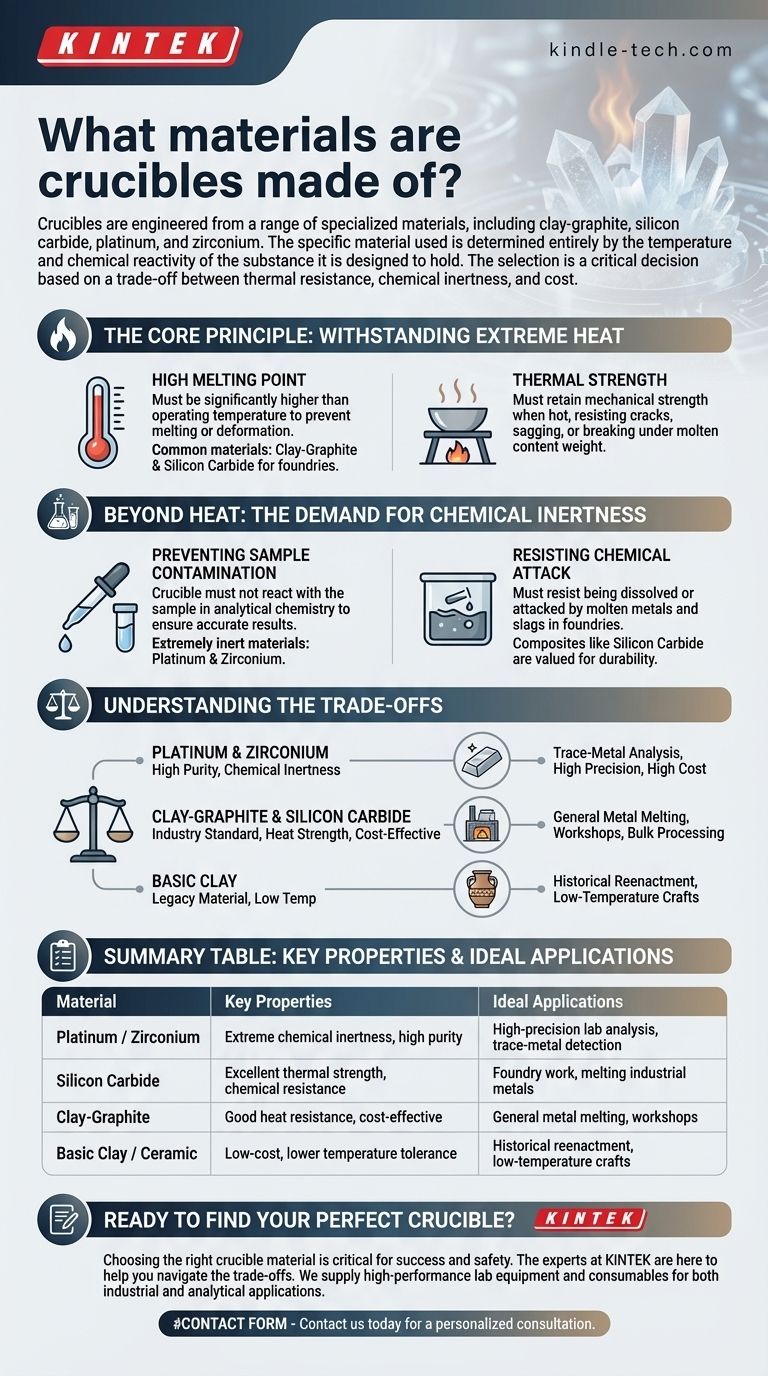

The Core Principle: Withstanding Extreme Heat

The most fundamental requirement of any crucible is its ability to maintain structural integrity at incredibly high temperatures. This is achieved through two primary material properties.

High Melting Point

A crucible must have a melting point significantly higher than the operating temperature of the process. This prevents the crucible itself from melting, deforming, or failing during use.

Materials like clay-graphite and silicon carbide are common in foundries because their melting points far exceed those of common metals like aluminum, brass, and even iron.

Thermal Strength

Surviving heat is about more than just not melting. The material must also retain its mechanical strength when hot, resisting cracks, sagging, or breaking under the weight of its molten contents.

Beyond Heat: The Demand for Chemical Inertness

For many applications, especially in science and analysis, heat resistance is not enough. The crucible must also be chemically non-reactive.

Preventing Sample Contamination

In a laboratory setting, the goal is often to analyze a substance for its precise chemical composition. Any reaction between the crucible and the sample would contaminate the results.

This is why crucibles for analytical chemistry are made from extremely inert materials like platinum or zirconium. They ensure that the only elements detected are from the sample itself, not the container.

Resisting Chemical Attack

In a foundry, molten metals and slags can be highly corrosive. The crucible material must be able to resist being chemically attacked or dissolved by its contents over repeated cycles.

This chemical resilience, combined with thermal strength, is why composites like silicon carbide are valued for their durability in harsh melting environments.

Understanding the Trade-offs

The ideal crucible material does not exist; every choice involves balancing performance requirements against practical limitations, primarily cost.

The Cost of Purity: Platinum and Zirconium

Platinum and zirconium offer unparalleled purity and resistance to chemical attack, but they are exceptionally expensive.

Their use is justified only in applications like trace-metal analysis, where even the slightest contamination would invalidate the results and the cost of failure is high.

The Workhorses: Clay-Graphite and Silicon Carbide

These composite materials represent the industry standard for most metal melting. They offer an excellent balance of high-temperature strength, good service life, and reasonable cost.

While not as inert as platinum, they are resilient enough for bulk processing where minor, acceptable levels of interaction with the melt are not a primary concern.

The Legacy Material: Basic Clay

Historically, crucibles were made from simple clay. While functional for lower-temperature metals used by ancient civilizations, they lack the strength and heat resistance needed for modern industrial applications.

Making the Right Choice for Your Application

Your final decision must be guided by the specific demands of your task.

- If your primary focus is high-purity lab analysis: You must use a highly inert material like platinum or zirconium to guarantee accurate, uncontaminated results.

- If your primary focus is melting metals in a foundry or workshop: A durable composite like clay-graphite or silicon carbide will provide the necessary heat resistance and strength cost-effectively.

- If your primary focus is historical reenactment or low-temperature craftwork: A basic ceramic or traditional clay crucible may be sufficient for your needs.

Ultimately, selecting the right crucible is about matching the material's properties to the unique thermal and chemical demands of your work.

Summary Table:

| Material | Key Properties | Ideal Applications |

|---|---|---|

| Platinum / Zirconium | Extreme chemical inertness, high purity | High-precision lab analysis, trace-metal detection |

| Silicon Carbide | Excellent thermal strength, chemical resistance | Foundry work, melting industrial metals |

| Clay-Graphite | Good heat resistance, cost-effective | General metal melting, workshops |

| Basic Clay / Ceramic | Low-cost, lower temperature tolerance | Historical reenactment, low-temperature crafts |

Ready to Find Your Perfect Crucible?

Choosing the right crucible material is critical for the success and safety of your work. The experts at KINTEK are here to help you navigate the trade-offs between heat resistance, chemical inertness, and cost.

We supply high-performance lab equipment and consumables, including a full range of crucibles for both industrial and analytical applications. Let us help you select the ideal crucible to ensure accurate results, improve efficiency, and extend the life of your equipment.

Contact us today for a personalized consultation and get the right tool for your specific thermal and chemical demands.

Visual Guide

Related Products

- High Purity Pure Graphite Crucible for Electron Beam Evaporation

- High Purity Pure Graphite Crucible for Evaporation

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

People Also Ask

- What is magnetron sputtering machine? Precision Thin-Film Deposition for Advanced Materials

- What are the disadvantages of DC magnetron sputtering? Key Limitations for Your Lab

- What is the fundamental of magnetron sputtering? Master High-Quality Thin Film Deposition

- What are the effects of magnetron sputtering? Achieve High-Quality, Durable Thin Films for Your Lab

- How does a magnetron sputtering work? A Guide to High-Quality Thin Film Deposition