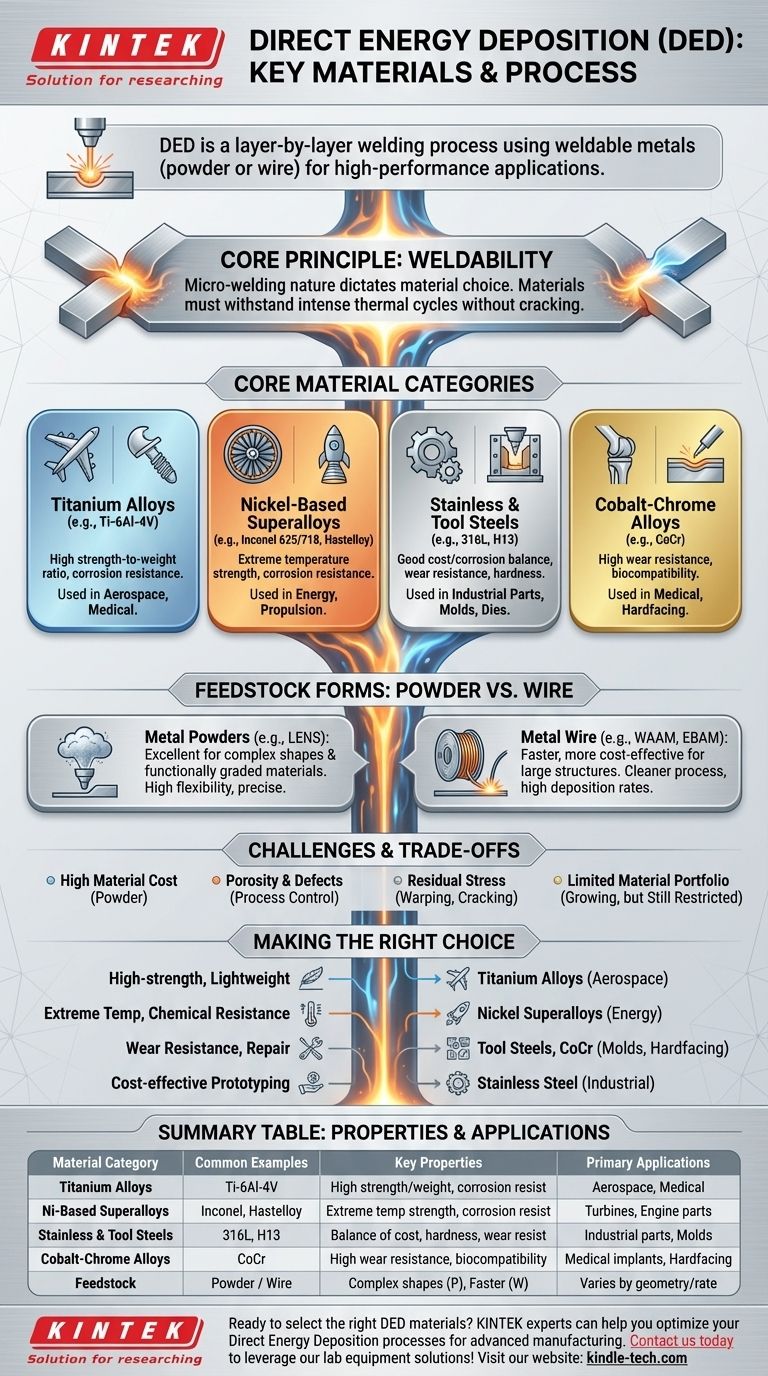

Direct Energy Deposition (DED) processes primarily work with weldable metals and metal alloys. These materials are fed into the process as either a fine powder or a thin wire. The most common categories include titanium alloys, nickel-based superalloys, stainless steels, and tool steels, which are chosen for their high performance in demanding applications like aerospace, defense, and industrial repair.

The central principle governing DED materials is weldability. Because the process involves melting and fusing material layer-by-layer, any metal or alloy that can be successfully welded is a strong candidate for DED. The choice between using a powder or a wire feedstock is the other key variable.

The "Why": It's All About Weldability

To understand DED materials, it's essential to see the process for what it is: a highly precise, automated, layer-by-layer welding operation. This single concept dictates nearly all material constraints and possibilities.

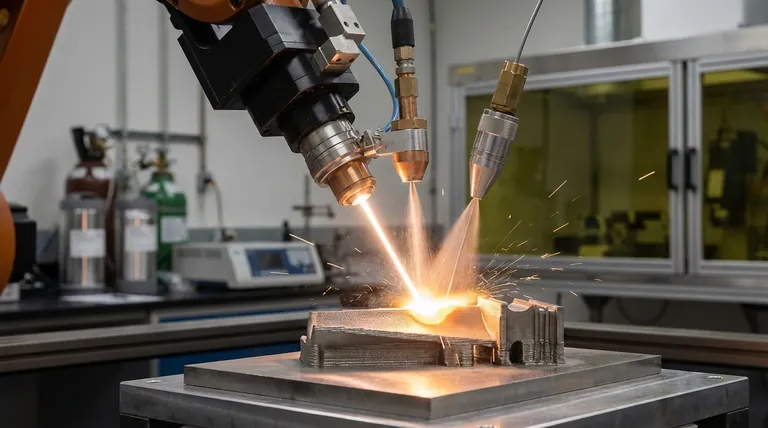

The DED Process as Micro-Welding

A DED system uses a focused energy source—typically a laser or an electron beam—to create a small molten pool of metal on a substrate or a previously deposited layer.

New material, either powder or wire, is then precisely fed into this molten pool. It melts, fuses with the existing material, and solidifies as the energy source moves on, building the part up layer by layer.

The Impact on Material Selection

This micro-welding nature means that materials prone to cracking or developing brittle phases upon rapid heating and cooling are poor candidates for DED.

Conversely, alloys with excellent weldability, like Ti-6Al-4V or Inconel 718, are industry workhorses because they can withstand these intense thermal cycles without failing.

Core Material Categories in DED

While the potential list is long, a few key categories represent the vast majority of DED applications due to their proven performance and established process parameters.

Titanium Alloys

Titanium, especially Ti-6Al-4V, is a cornerstone of DED. It is used extensively in the aerospace and medical industries for its exceptional strength-to-weight ratio and corrosion resistance.

Nickel-Based Superalloys

Alloys like Inconel (625, 718) and Hastelloy are prized for their ability to maintain mechanical strength at extreme temperatures. This makes them ideal for turbine blades, engine components, and chemical processing equipment.

Stainless and Tool Steels

Various grades of stainless steel (e.g., 316L) offer a good balance of cost, corrosion resistance, and mechanical properties, making them popular for industrial parts and prototypes.

Tool steels (e.g., H13) are used for their hardness and wear resistance, allowing for the repair and manufacturing of dies, molds, and cutting tools.

Cobalt-Chrome Alloys

These alloys are known for their incredible wear resistance, hardness, and biocompatibility. They are often used for hardfacing applications (adding a durable coating to a part) and for creating medical implants.

Powder vs. Wire: The Two Forms of DED Material

The physical form of the material is a critical distinction that impacts the equipment, process, and final part characteristics.

Metal Powders

Powder-based DED (such as LENS) uses a stream of inert gas to deliver fine metal powder into the melt pool. The powder must have good sphericity and flowability for a consistent feed rate.

This method offers excellent geometric flexibility and is well-suited for creating complex shapes and functionally graded materials, where the alloy composition can be changed during the build.

Metal Wire

Wire-based DED (such as WAAM or EBAM) uses standard welding wire as its feedstock. This approach is often faster, more cost-effective, and results in a cleaner process with less wasted material.

Wire DED typically produces parts with a rougher surface finish but allows for very high deposition rates, making it ideal for building large-scale structures.

Understanding the Trade-offs and Material Challenges

While powerful, DED is not without its material-related complexities. Understanding these limitations is key to successful implementation.

High Material Cost

Specialized, gas-atomized metal powders required for DED are significantly more expensive than their bulk counterparts, such as metal bar stock used in traditional machining.

Porosity and Defects

Improper process parameters can lead to gas becoming trapped within the solidifying metal, creating tiny voids or pores. This porosity can compromise the mechanical integrity of the final part.

Residual Stress

The repeated, localized heating and cooling inherent in the DED process builds up internal stresses within the part. Without proper management, this stress can lead to warping, distortion, or even cracking.

Limited Material Portfolio

While growing, the range of qualified materials for DED is still smaller than that available for conventional manufacturing processes like casting or forging. Some common engineering alloys, particularly certain aluminum grades, remain challenging to process reliably.

Making the Right Choice for Your Application

Selecting the correct material is about matching its properties to the intended function of the part.

- If your primary focus is high-strength, lightweight parts: Titanium alloys are the industry standard for aerospace and high-performance applications.

- If your primary focus is extreme temperature and chemical resistance: Nickel-based superalloys like Inconel are the clear choice for energy, propulsion, and processing industries.

- If your primary focus is wear resistance or part repair: Tool steels and cobalt-chrome alloys provide the hardness needed for hardfacing and restoring worn components.

- If your primary focus is cost-effective prototyping or general industrial use: Stainless steel offers a reliable and well-understood baseline for a wide range of applications.

Ultimately, viewing Direct Energy Deposition through the lens of advanced welding is the key to mastering its material selection and unlocking its full potential.

Summary Table:

| Material Category | Common Examples | Key Properties | Primary Applications |

|---|---|---|---|

| Titanium Alloys | Ti-6Al-4V | High strength-to-weight ratio, corrosion resistance | Aerospace, medical implants |

| Nickel-Based Superalloys | Inconel 625/718, Hastelloy | Extreme temperature strength, corrosion resistance | Turbine blades, engine components |

| Stainless & Tool Steels | 316L, H13 | Good corrosion resistance, hardness, wear resistance | Industrial parts, molds, dies |

| Cobalt-Chrome Alloys | CoCr | High wear resistance, biocompatibility | Medical implants, hardfacing |

| Feedstock Form | Powder vs. Wire | Powder: Complex shapes, graded materials. Wire: Faster, cost-effective for large parts | Varies by geometric needs and deposition rate |

Ready to select the right DED materials for your high-performance applications? KINTEK specializes in lab equipment and consumables, serving laboratory needs for advanced manufacturing and materials research. Our experts can help you navigate material selection for titanium alloys, nickel superalloys, and other weldable metals to optimize your Direct Energy Deposition processes. Contact us today to discuss your specific requirements and leverage our expertise in lab equipment solutions for additive manufacturing!

Visual Guide

Related Products

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Automatic Lab Cold Isostatic Press CIP Machine Cold Isostatic Pressing

- Automatic Laboratory Heat Press Machine

People Also Ask

- How to measure optical properties of thin films? Master Spectroscopic Ellipsometry for Precise Results

- What are the furnace used in metals? A Guide to Melting, Alloying, and Heat Treatment

- What is the difference between dry oven and incubator? Choosing the Right Equipment for Your Lab

- What is the stress in sputtered thin films? Control Internal Forces for Reliable Film Performance

- Why is the metal melting temperature important? The Key to Manufacturing & Performance

- Can all metal be heat-treated? Understanding the Role of Alloy Composition in Metal Hardening

- What is the effect of temperature on hydrogen embrittlement? The Critical Role of Temperature in Material Failure

- What is the difference between submerged arc furnace and electric arc furnace? Choosing the Right Smelting vs. Melting Technology