At its core, hot isostatic pressing (HIP) is a transformative thermal process used on a wide range of high-performance materials. It is most commonly applied to metals like titanium and aluminum, various powdered superalloys, and advanced ceramics. The process is not limited to raw materials; it is also a critical finishing step for components produced by casting, sintering, and additive manufacturing.

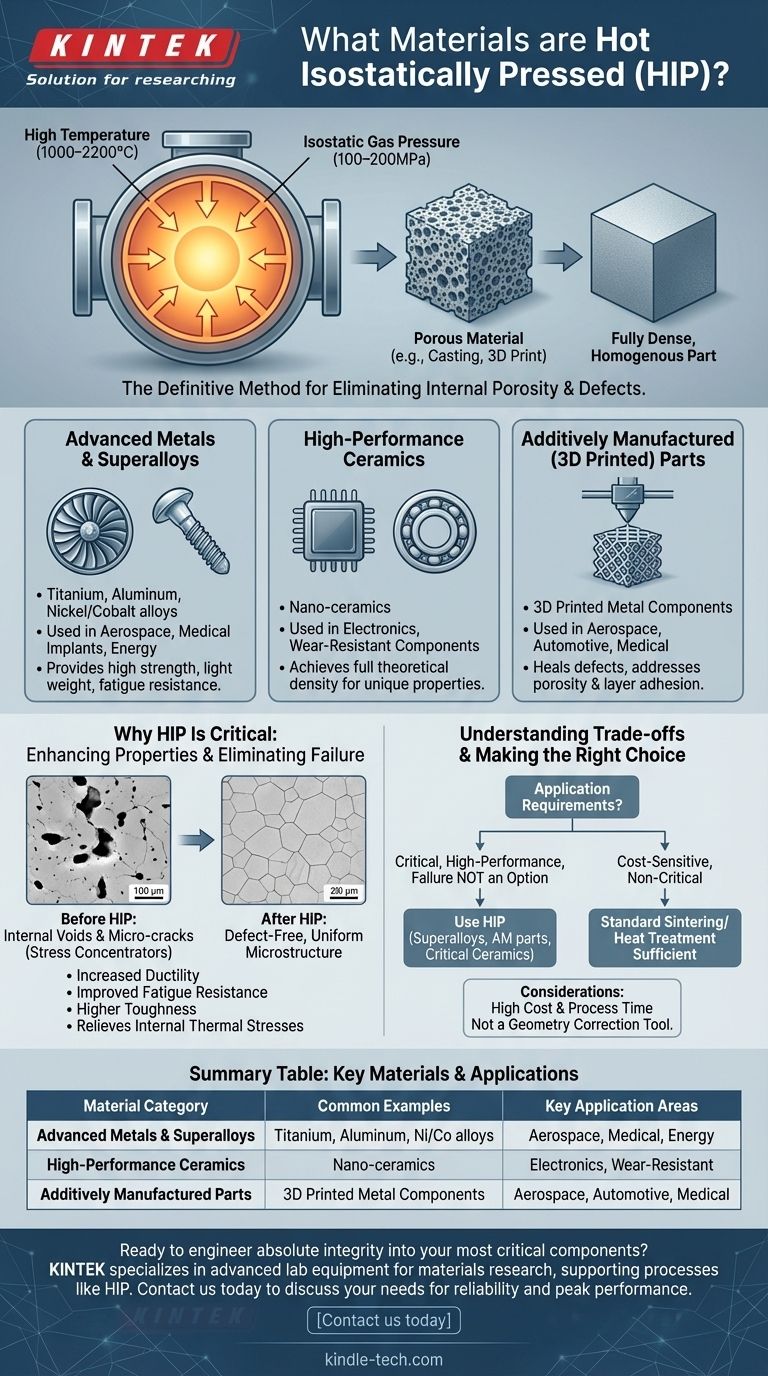

Hot isostatic pressing is best understood not by the specific materials it can process, but by the problem it solves. It is the definitive method for eliminating internal porosity and defects, creating fully dense parts with superior mechanical properties for applications where failure is not an option.

Why HIP Is a Critical Manufacturing Step

Hot isostatic pressing subjects a component to both high temperature (1000–2200°C) and isostatic gas pressure (100–200MPa). This combination achieves results that heat or pressure alone cannot.

The Fundamental Goal: Achieving Full Density

Many manufacturing methods, especially casting and 3D printing, leave behind microscopic internal voids or pores. HIP uses high pressure to physically squeeze the material from all directions, collapsing these voids and bonding the material on a metallurgical level.

This process transforms a component from a near-net shape into a fully dense, homogenous structure.

Eliminating Failure Points at the Source

Internal defects like pores, micro-cracks, and poor layer adhesion in 3D printed parts act as stress concentrators. Under load, these tiny flaws can grow and lead to premature component failure.

HIP eliminates these internal defects, significantly increasing the material's stability and service life, which is essential for parts in extreme environments like power units or subsea pipelines.

Enhancing Mechanical Properties

By creating a uniform, defect-free microstructure, HIP directly improves key material properties. Parts treated with HIP exhibit measurably higher ductility, fatigue resistance, and overall toughness.

The process also relieves internal thermal stresses that can build up during casting or additive manufacturing.

Key Material Categories and Applications

While many materials can be subjected to HIP, the process is typically reserved for those used in demanding, high-performance applications.

Advanced Metals and Superalloys

Metals like titanium, aluminum, and various nickel-based or cobalt-based superalloys are primary candidates for HIP.

These are frequently used in aerospace, medical implant, and energy applications where the combination of light weight, high strength, and resistance to fatigue is non-negotiable.

High-Performance Ceramics

Certain advanced materials, such as nano-ceramics, are notoriously difficult to densify using traditional sintering methods.

HIP provides the necessary combination of heat and pressure to achieve full theoretical density, unlocking the unique properties of these materials for use in cutting-edge electronic or wear-resistant applications.

Additively Manufactured (3D Printed) Components

Hot isostatic pressing is becoming an indispensable step in the additive manufacturing workflow. It is the most effective way to address the inherent porosity and inconsistent layer adhesion common in 3D printed metal parts.

HIP effectively heals these defects, transforming a printed part into a fully consolidated component with properties that can meet or exceed those of traditionally manufactured counterparts.

Understanding the Trade-offs and Considerations

While powerful, HIP is a specialized process that is not suitable or necessary for every application. Understanding its limitations is key to using it effectively.

High Cost and Process Time

The equipment required to generate extreme heat and pressure safely is expensive to build and operate. The heating, pressurizing, and cooling cycles can also be time-consuming.

Because of this, HIP adds significant cost and lead time to the manufacturing process.

Not a Geometry Correction Tool

HIP is a densification process, not a shaping one. It will not fix surface imperfections, correct dimensional inaccuracies, or alter the overall geometry of a part.

The component must already be in its near-net shape before it enters the HIP vessel.

When Is It Truly Necessary?

The decision to use HIP is an engineering and economic one. It is reserved for applications where the potential cost of component failure—in terms of safety, financial loss, or mission failure—far outweighs the cost of the HIP process itself.

Making the Right Choice for Your Component

Integrating HIP into your manufacturing plan depends entirely on the performance requirements of the final part.

- If your primary focus is maximum performance and reliability: Use HIP for critical components, especially those made from superalloys or via additive manufacturing, to guarantee a defect-free microstructure.

- If your primary focus is densifying hard-to-sinter materials: HIP is the definitive method for achieving full density in advanced ceramics and certain powder metallurgy composites.

- If your primary focus is cost-sensitive, non-critical parts: HIP is likely an unnecessary expense, and standard sintering or heat treatment will be sufficient for the application.

Ultimately, employing hot isostatic pressing is a strategic decision to engineer absolute material integrity into your most critical components.

Summary Table:

| Material Category | Common Examples | Key Application Areas |

|---|---|---|

| Advanced Metals & Superalloys | Titanium, Aluminum, Nickel/Cobalt alloys | Aerospace, Medical Implants, Energy |

| High-Performance Ceramics | Nano-ceramics | Electronics, Wear-Resistant Components |

| Additively Manufactured Parts | 3D Printed Metal Components | Aerospace, Automotive, Medical |

Ready to engineer absolute integrity into your most critical components?

KINTEK specializes in providing advanced lab equipment and consumables for materials research and development, including technologies that support processes like Hot Isostatic Pressing. If you are working with high-performance metals, superalloys, ceramics, or additive manufacturing and require guaranteed material density and superior mechanical properties, our expertise can help.

Contact us today to discuss how we can support your laboratory's needs for reliability and peak performance.

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Double Plate Heating Press Mold for Lab

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Metallographic Specimen Mounting Machine for Laboratory Materials and Analysis

People Also Ask

- What are the risk and protective factors of CVD? Take Control of Your Heart Health Today

- How does a high-speed disperser contribute to graphene oxide synthesis? Optimize Exfoliation & Chemical Efficiency

- How does the stirring speed affect silver nanowires morphology? Master Agitation for High-Purity Synthesis

- What is the high temperature variety of quartz? Unlock the Secrets of Beta-Quartz & Fused Quartz

- What is the maximum service temperature for brazing? A Guide to Joint Integrity & Longevity

- What are the disadvantages of graphene coating? High Cost, Difficult Application & Misleading Marketing

- What affects the melting point of a substance? Uncover the Key Factors & Forces

- What is the difference between gasification and combustion of biomass? Choosing the Right Biomass Conversion Path