To be clear, the most common materials used in press forming are metals with high formability, primarily low-carbon steel, aluminum alloys, stainless steel, and copper alloys. The provided references discuss sintering, which is a fundamentally different manufacturing process involving powdered materials, and are not applicable to the sheet metal process of press forming.

The critical factor in selecting a material for press forming is not just its type, but its specific mechanical properties. The goal is to find a material with sufficient ductility to be shaped under immense pressure without cracking or failing.

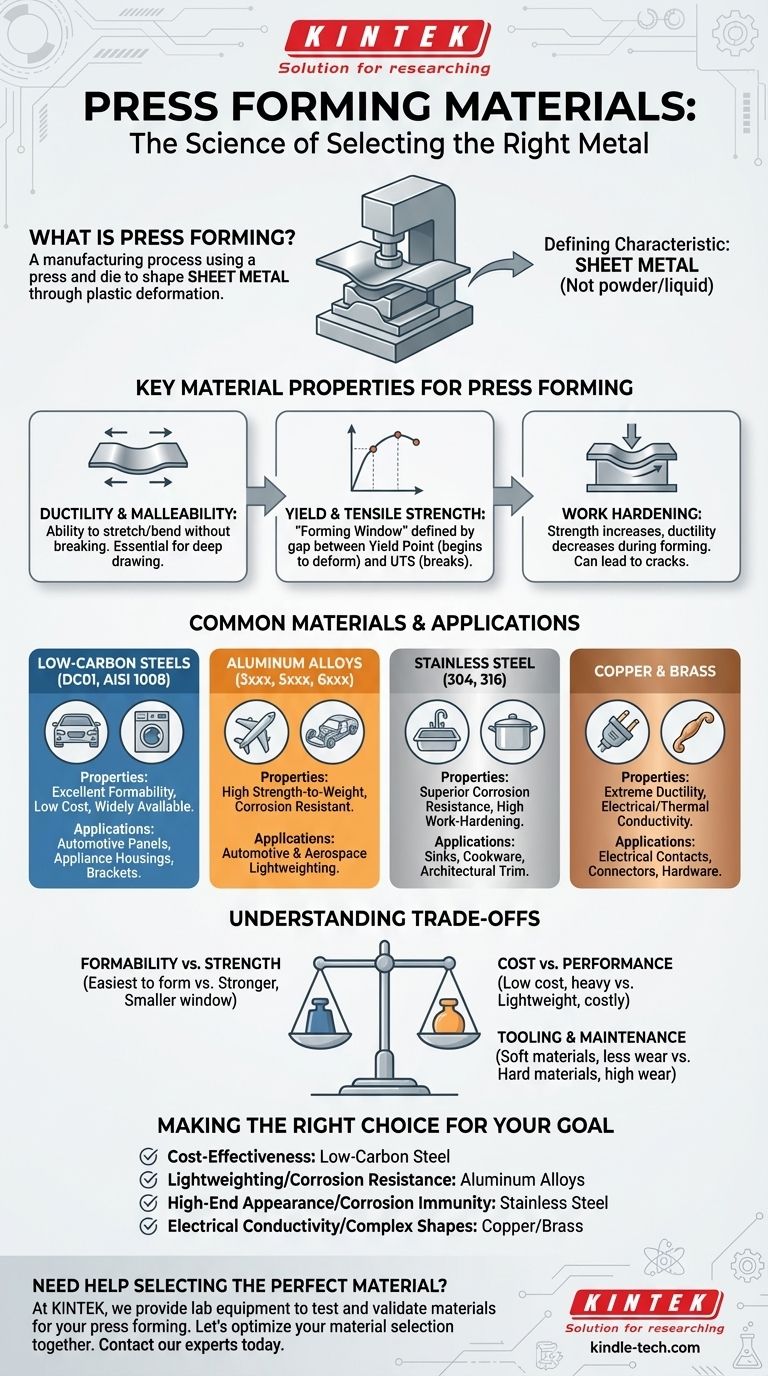

What is Press Forming?

Press forming, often used interchangeably with stamping, is a manufacturing process that uses a press and a die to shape sheet metal. The material is plastically deformed to create the desired shape.

The Defining Characteristic: Sheet Metal

Press forming almost exclusively works with sheet metal. This is a key distinction from processes like sintering or casting, which start with powder or liquid material. The properties of the sheet stock are paramount.

Key Material Properties for Press Forming

Choosing the right material requires understanding the forces at play. The material must be able to stretch, bend, and flow into the die shape.

Ductility and Malleability

Ductility is a material's ability to be stretched or drawn into a wire without breaking. This property is essential for deep drawing operations where a flat sheet is formed into a cup-like shape.

Malleability is the ability to be hammered or pressed into shape without breaking. Both are crucial for successful forming.

Yield Strength and Tensile Strength

Yield strength is the point at which a material begins to deform permanently. It must be low enough for the press to shape the part.

Ultimate tensile strength (UTS) is the maximum stress a material can withstand while being stretched before it begins to neck down and break. The gap between yield strength and UTS defines the "forming window."

Work Hardening

As a material is formed, it undergoes work hardening (or strain hardening), which increases its strength but reduces its ductility. Engineers must account for this, as excessive work hardening can lead to cracks in complex parts.

Common Materials and Their Applications

Each material offers a unique combination of formability, strength, cost, and corrosion resistance.

Low-Carbon Steels

These are the workhorses of the press forming industry. Materials like DC01 or AISI 1008 are inexpensive, widely available, and have excellent formability due to their low carbon content. They are used in automotive body panels, appliance housings, and structural brackets.

Aluminum Alloys

Alloys in the 3xxx, 5xxx, and 6xxx series are popular for press forming. They offer an excellent strength-to-weight ratio and natural corrosion resistance. They are critical in the automotive and aerospace industries for lightweighting components.

Stainless Steels

Austenitic grades like 304 and 316 are commonly used. While more difficult to form than low-carbon steel due to their high work-hardening rate, they provide superior corrosion resistance and a high-quality surface finish. This makes them ideal for kitchen sinks, cookware, and decorative trim.

Copper and Brass

These materials are extremely ductile and easy to form. They also offer excellent electrical and thermal conductivity. They are often chosen for electrical contacts, connectors, and decorative hardware.

Understanding the Trade-offs

No single material is perfect for every application. The selection process is a balance of competing factors.

Formability vs. Strength

Generally, materials that are easiest to form (high ductility, low yield strength) are not the strongest. High-strength steels, for example, require significantly more force to form and have a smaller "forming window," increasing the risk of defects.

Cost vs. Performance

Low-carbon steel is the most cost-effective option, but it is heavy and requires a protective coating to prevent rust. Aluminum is lightweight and corrosion-resistant but comes at a higher material cost.

Tooling and Maintenance

Harder materials like high-strength steel or stainless steel cause more wear on the press tooling. This leads to higher tooling costs and more frequent maintenance, which must be factored into the total cost of production.

Making the Right Choice for Your Goal

Your final decision should be driven by the primary requirement of your component.

- If your primary focus is cost-effectiveness for mass production: Low-carbon steel is almost always the default choice due to its low cost and excellent formability.

- If your primary focus is lightweighting and corrosion resistance: Aluminum alloys are the ideal solution, especially in the automotive and aerospace sectors.

- If your primary focus is high-end appearance and corrosion immunity: Stainless steel is the premium option for consumer goods and architectural applications.

- If your primary focus is electrical conductivity or ease of forming complex shapes: Copper or brass provides superior performance in these specific niches.

Ultimately, selecting the right material is a critical engineering decision that balances the desired performance of the final part with the practical realities of manufacturing.

Summary Table:

| Material | Key Properties | Common Applications |

|---|---|---|

| Low-Carbon Steel | Excellent formability, low cost, widely available | Automotive body panels, appliance housings, brackets |

| Aluminum Alloys | High strength-to-weight ratio, corrosion resistant | Automotive & aerospace lightweight components |

| Stainless Steel | Superior corrosion resistance, high work-hardening rate | Kitchen sinks, cookware, architectural trim |

| Copper/Brass | Extreme ductility, excellent electrical conductivity | Electrical contacts, connectors, decorative hardware |

Need help selecting the perfect material for your press forming project? The right choice is critical for balancing performance, cost, and manufacturability. At KINTEK, we specialize in providing the lab equipment and consumables needed to test and validate materials for your manufacturing processes. Our expertise helps you ensure your chosen material meets all mechanical property requirements before full-scale production.

Let's optimize your material selection together. Contact our experts today to discuss your specific application and how we can support your laboratory's needs.

Visual Guide

Related Products

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates Split Manual Laboratory Hot Press

People Also Ask

- What is the function of a laboratory high-temperature hydraulic press? Optimize MEA Fabrication for HCl Electrolysis

- What is a hot hydraulic press? Harness Heat and Pressure for Advanced Manufacturing

- What are heated hydraulic presses used for? Molding Composites, Vulcanizing Rubber, and More

- What is a heated hydraulic press used for? Essential Tool for Curing, Molding, and Laminating

- How does a vacuum furnace environment influence sintered Ruthenium powder? Achieve High Purity and Theoretical Density