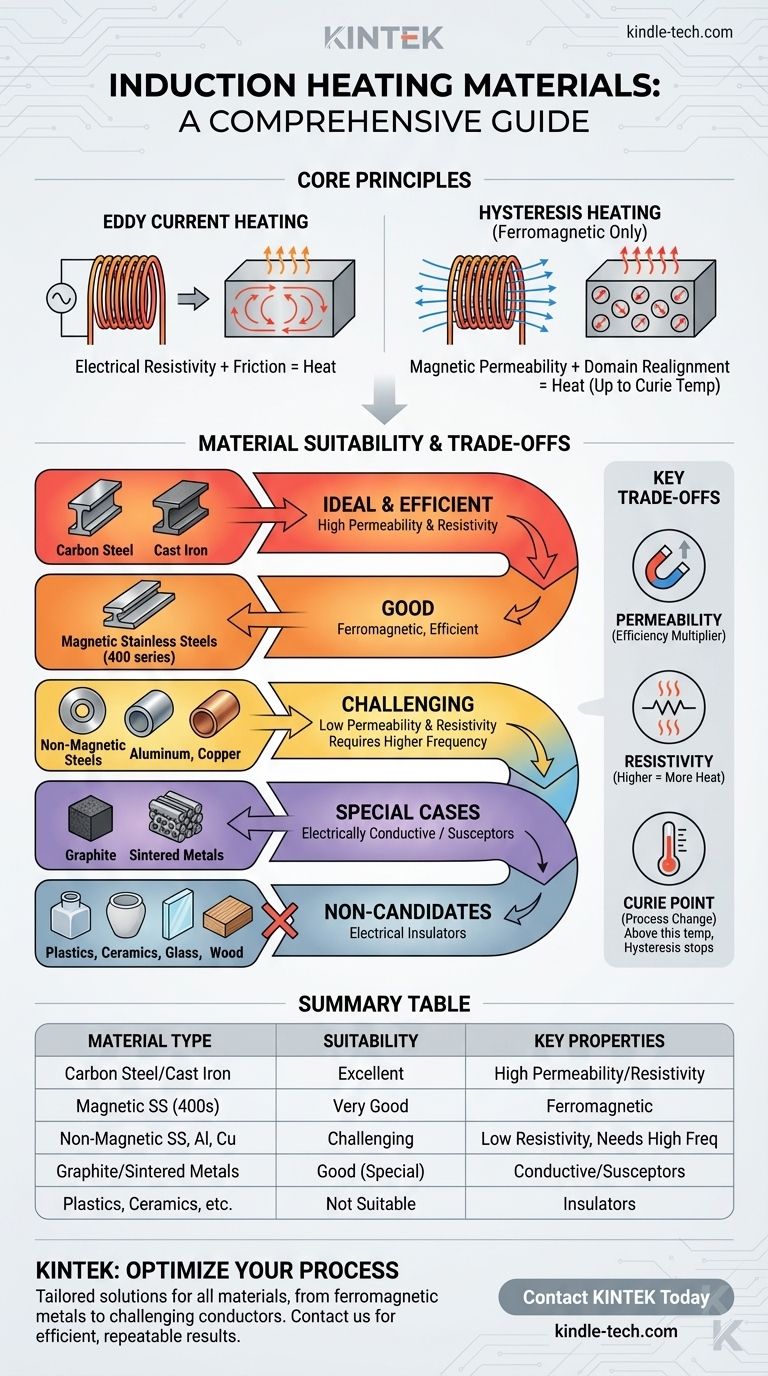

In principle, any electrically conductive material can be heated by induction, but the effectiveness varies dramatically. The best materials are ferromagnetic metals like iron and most steels, which heat rapidly and efficiently. Other conductive materials like specific stainless steels, aluminum, copper, brass, and even graphite can be heated, but they require different process parameters and are generally less efficient.

The success of induction heating is not simply about electrical conductivity. It is a combination of two key properties: a material's magnetic permeability, which multiplies the magnetic effect, and its electrical resistivity, which determines how effectively induced currents generate heat.

The Core Principles of Material Selection

To understand why some materials work better than others, you must understand the two heating mechanisms at play.

Eddy Current Heating

This is the universal principle of induction heating that applies to all conductive materials.

An alternating current in the induction coil creates a fluctuating magnetic field. This field, in turn, induces circulating electrical currents within the workpiece, known as eddy currents.

Every material has some resistance to the flow of electricity. As these eddy currents flow against the material's electrical resistivity, they generate friction and heat. This is known as Joule heating (P = I²R).

Hysteresis Heating

This is a powerful secondary effect that only occurs in ferromagnetic materials like iron, nickel, cobalt, and most steels.

These materials are composed of small magnetic regions called domains. The rapidly alternating magnetic field from the coil forces these domains to flip their polarity back and forth millions of times per second.

This rapid realignment creates immense internal friction, which generates a significant amount of heat. Hysteresis heating is extremely efficient but stops working once the material reaches its Curie temperature, the point at which it loses its magnetic properties.

A Material-by-Material Breakdown

The suitability of a material is a direct result of the principles above.

Ideal Candidates: Carbon Steel and Cast Iron

These are the easiest and most efficient materials to heat with induction. They possess both high magnetic permeability (enabling powerful hysteresis heating) and relatively high electrical resistivity (enabling effective eddy current heating). This dual-action heating makes the process very fast.

Good Candidates: Magnetic Stainless Steels

Stainless steels in the 400 series (e.g., 410, 430) are ferritic and magnetic. They behave very similarly to carbon steel and heat very well, making them excellent candidates for induction processes like hardening or brazing.

Challenging Candidates: Non-Magnetic Steels, Copper, and Aluminum

Non-magnetic stainless steels (like the common 304 or 316 series), aluminum, and copper lack magnetic permeability. This means they can only be heated by eddy currents.

Furthermore, materials like copper and aluminum have very low electrical resistivity. This makes it harder to generate heat and requires significantly higher frequencies to concentrate the eddy currents near the surface (a phenomenon known as the "skin effect"). Heating them is possible but far less energy-efficient.

Special Cases: Graphite and Sintered Metals

Graphite is not a metal but is electrically conductive. It can be heated effectively with induction and is often used as a crucible to indirectly heat non-conductive materials. Sintered metals, like tungsten carbide, can also be heated depending on their composition and binder material (e.g., cobalt).

Non-Candidates: Insulators

Materials like plastics, ceramics, glass, and wood are electrical insulators. The magnetic field passes through them without inducing any currents, so they cannot be heated directly by induction.

Understanding the Key Trade-offs

Selecting a material isn't just about whether it can be heated, but how controllably and efficiently it happens.

Permeability: The Efficiency Multiplier

The presence of magnetic permeability makes a material dramatically easier to heat. The energy required to heat a piece of steel to its Curie temperature (around 770°C / 1420°F) is far lower than the energy required to achieve the same temperature in a similar-sized piece of aluminum.

Resistivity: The Counterintuitive Factor

While it may seem backward, for a given induced current, a higher electrical resistivity results in more heat. This is why stainless steel (with higher resistivity) heats more easily via eddy currents than copper (with very low resistivity), even though copper is a "better" conductor.

The Curie Point: A Built-in Process Change

For heat treating steel, the Curie temperature is a critical process landmark. Below this temperature, heating is rapid due to both hysteresis and eddy currents. Above it, hysteresis stops, and the rate of heating slows down significantly. This self-regulating aspect can be used to prevent overheating in some applications.

Making the Right Choice for Your Goal

Your application dictates the ideal material and process parameters.

- If your primary focus is maximum heating speed and efficiency: Choose ferromagnetic materials like carbon steel or magnetic stainless steel, as their high permeability provides rapid heating.

- If your primary focus is heating non-magnetic or low-resistivity materials like aluminum or copper: You must use a higher-frequency induction system to compensate for the lack of permeability and low resistivity.

- If your primary focus is precise temperature control for heat treating: Be acutely aware of the Curie temperature, as the heating characteristics of your steel workpiece will change significantly once it passes this point.

- If you need to heat a non-conductive material: Consider using a conductive crucible (like graphite or silicon carbide) to act as a susceptor, which gets hot via induction and transfers that heat to your target material.

Understanding these material properties empowers you to design an induction process that is not only effective but also highly efficient and repeatable.

Summary Table:

| Material Type | Induction Heating Suitability | Key Properties |

|---|---|---|

| Carbon Steel & Cast Iron | Excellent | High magnetic permeability & electrical resistivity |

| Magnetic Stainless Steels (400 series) | Very Good | Ferromagnetic, good for hardening/brazing |

| Non-Magnetic Steels, Aluminum, Copper | Challenging | Low resistivity, requires high frequency |

| Graphite & Sintered Metals | Good (Special Cases) | Electrically conductive, can act as susceptors |

| Plastics, Ceramics, Glass, Wood | Not Suitable | Electrical insulators, cannot be heated directly |

Ready to optimize your induction heating process? KINTEK specializes in lab equipment and consumables, providing tailored solutions for your laboratory's material heating needs. Whether you're working with ferromagnetic metals or challenging conductors like aluminum and copper, our expertise ensures efficient, repeatable results. Contact us today to discuss how we can enhance your induction heating applications!

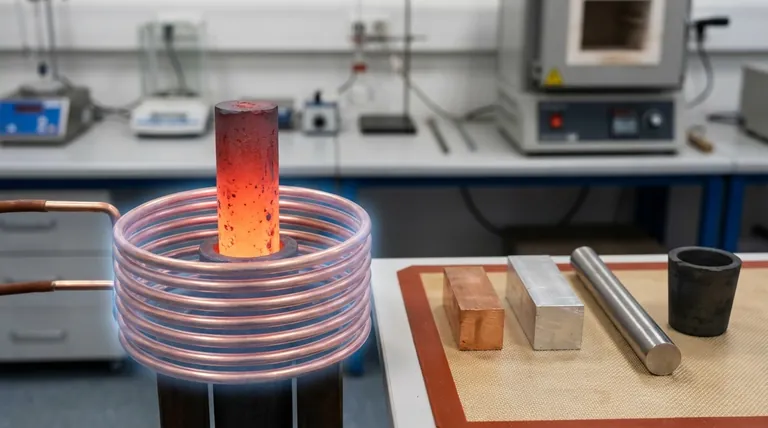

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Double Plate Heating Press Mold for Lab

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is a silicon carbide heating element? Unlock Extreme Heat for Industrial Processes

- What is silicon carbide rod heated to high temperature used as? A Premier Heating Element for Extreme Environments

- What is SiC melting point? Discover the Extreme Thermal Stability of Silicon Carbide

- What material is used for making heating element? Choose the Right Alloy for Your Application

- What kind of metal is used in heating elements? A Guide to Materials for Every Temperature & Atmosphere