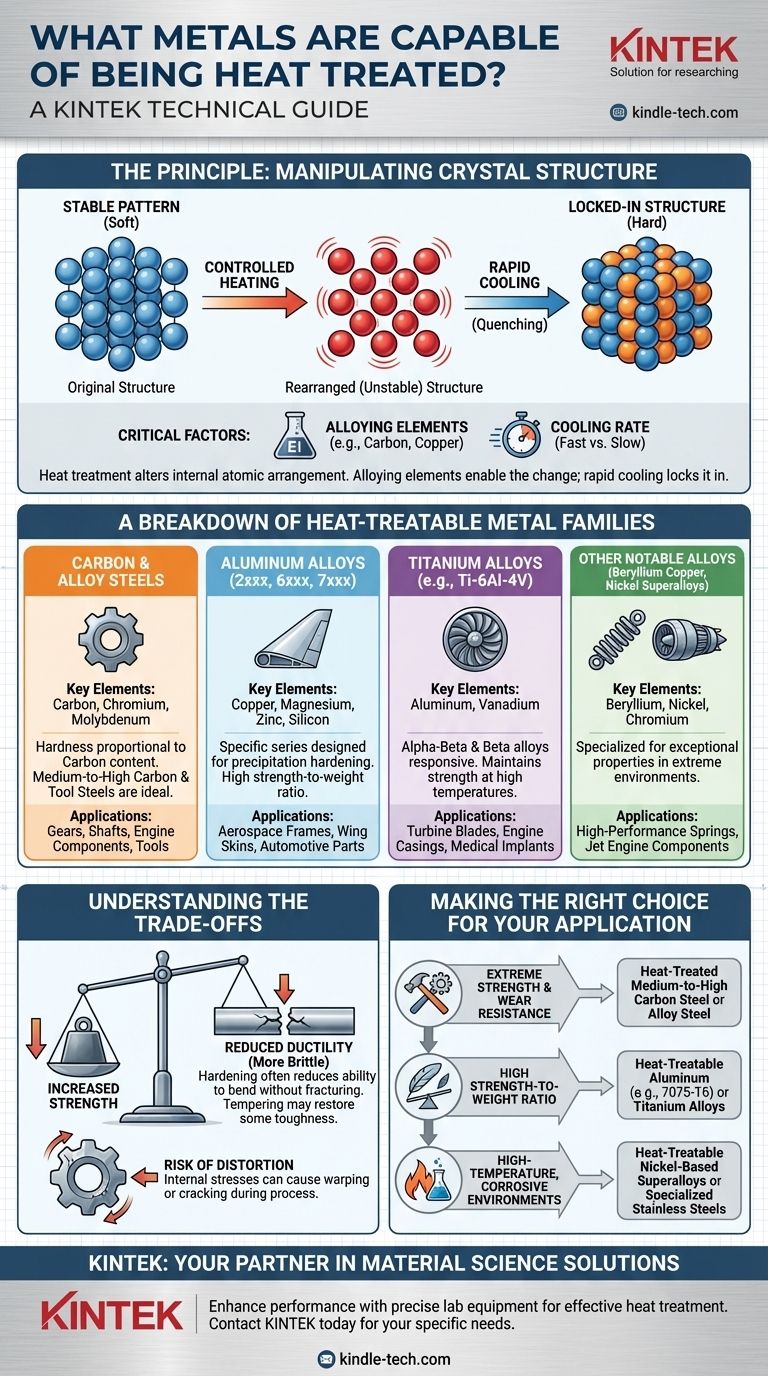

In short, not all metals can be heat treated. The ability to fundamentally change a metal's properties through heat treatment is reserved for specific alloys whose internal crystal structure can be manipulated. The most common examples are specific grades of steel, aluminum, titanium, and certain copper or nickel-based alloys. This capability is entirely dependent on the alloy's chemical composition and its metallurgical structure.

The critical factor determining if a metal can be heat treated is whether its internal atomic structure can be purposefully altered through controlled heating and cooling. This process locks in desirable characteristics, primarily increasing strength and hardness, by trapping the metal in a less stable, higher-performance state.

The Principle: What Makes a Metal Heat Treatable?

To make an informed decision, you must look beyond a simple list of metals and understand the mechanism that makes heat treatment possible. It's not magic; it's a manipulation of the metal's internal architecture at an atomic level.

It’s About Changing the Crystal Structure

Think of a metal's atoms as building blocks arranged in a neat, stable pattern. For certain alloys, heating them to a specific temperature causes these blocks to rearrange into a different, often denser, pattern.

This change is the key. By rapidly cooling the metal (a process called quenching), we don't give the atoms time to return to their original, softer arrangement. We effectively freeze them in their new, high-performance structure.

The Essential Role of Alloying Elements

Plain iron is not effectively heat treatable. But when you add carbon to create steel, everything changes. Carbon is the key that enables the crystal structure to be altered and locked into a hard state called martensite.

The same principle applies to other metals. Adding copper to aluminum or vanadium and aluminum to titanium creates alloys that can be strengthened through a different mechanism called precipitation hardening, or age hardening.

The Critical Factor of Cooling Rate

The speed of cooling is paramount. A slow cool allows the atoms to leisurely rearrange back to their soft, stable state. A very fast quench, often in water, brine, or oil, is what traps the high-strength structure. This control over the cooling rate is a fundamental part of any heat treatment process.

A Breakdown of Heat-Treatable Metal Families

While the principles are universal, they apply differently across various metal families. Knowing which series or grades within a family are treatable is crucial for material selection.

Carbon and Alloy Steels

This is the most well-known category. The ability of steel to be hardened is almost directly proportional to its carbon content.

Low-carbon steels (like 1018) have too little carbon to be significantly hardened through quenching. In contrast, medium-to-high carbon steels (like 1045 or 4140) and tool steels are designed specifically for heat treatment to achieve high hardness and wear resistance for parts like gears and engine components.

Aluminum Alloys

Pure aluminum is soft and cannot be hardened by heat treatment. However, specific alloy series are designed for it.

The most common heat-treatable series are 2xxx (copper as the main alloy), 6xxx (magnesium and silicon), and 7xxx (zinc). These are mainstays in the aerospace industry for components like fuselage frames and wing skins where high strength and low weight are critical.

Titanium Alloys

Similar to aluminum, not all titanium alloys are heat treatable. The capability depends on their crystal structure.

Alpha-Beta alloys (like the workhorse Ti-6Al-4V) and Beta alloys are responsive to heat treatment. They are used for high-performance applications like turbine blades, engine casings, and hydraulic fittings where strength must be maintained at elevated temperatures.

Other Notable Alloys

Some specialized alloys are also designed for heat treatment. Beryllium copper can be treated to achieve a hardness and tensile strength that is unmatched by other copper alloys. Likewise, nickel-based superalloys like Inconel 718 are heat treated to provide exceptional strength in the extreme high-temperature environments of jet engines and gas turbines.

Understanding the Trade-offs and Limitations

Heat treatment is a powerful tool, but it is not without its compromises. Acknowledging these trade-offs is the mark of a sound engineering decision.

Increased Strength Means Reduced Ductility

There is no free lunch in metallurgy. The process of making a metal harder and stronger almost invariably makes it more brittle. The hardened material has less ability to bend or deform before fracturing. A secondary process called tempering is often required after quenching to restore some toughness, though this comes at the expense of some peak hardness.

Not All Grades in a Family are Equal

It is a common and costly mistake to assume all "steels" or "aluminums" are the same. A 300 series stainless steel or a 5000 series aluminum alloy cannot be hardened by heat treatment. Their strengthening comes from cold working. Specifying a heat treatment for a non-heat-treatable alloy is a waste of time and money.

The Inherent Risk of Distortion

The extreme temperature changes and structural transformations involved in heat treatment induce massive internal stresses within a part. This can cause the material to warp, distort, or even crack if the process is not carefully controlled or if the part has a complex geometry with sharp corners or drastic changes in thickness.

Making the Right Choice for Your Application

Selecting the correct material requires matching its potential properties with the demands of the final application.

- If your primary focus is extreme strength and wear resistance: A heat-treated medium-to-high carbon steel or alloy steel is the most direct and cost-effective choice for components like gears, shafts, and tools.

- If your primary focus is a high strength-to-weight ratio: Heat-treatable aluminum alloys (like 7075-T6) or titanium alloys (like Ti-6Al-4V) are the definitive industry standards for aerospace and high-performance applications.

- If your primary focus is performance in high-temperature, corrosive environments: Heat-treatable nickel-based superalloys or specific precipitation-hardening stainless steels are engineered precisely for these challenges.

Ultimately, understanding why a metal can be heat treated is the key to leveraging its full potential for your specific engineering goal.

Summary Table:

| Heat-Treatable Metal Family | Key Alloying Elements | Common Applications |

|---|---|---|

| Carbon & Alloy Steels | Carbon, Chromium, Molybdenum | Gears, shafts, engine components, tools |

| Aluminum Alloys (2xxx, 6xxx, 7xxx) | Copper, Magnesium, Zinc, Silicon | Aerospace frames, wing skins, automotive parts |

| Titanium Alloys (e.g., Ti-6Al-4V) | Aluminum, Vanadium | Turbine blades, engine casings, medical implants |

| Other Alloys (Beryllium Copper, Nickel Superalloys) | Beryllium, Nickel, Chromium | High-performance springs, jet engine components |

Need to enhance the performance of your metal components? At KINTEK, we specialize in providing the precise lab equipment and consumables needed for effective heat treatment processes. Whether you're working with steel, aluminum, titanium, or specialized alloys, our solutions help you achieve superior strength, hardness, and durability. Let our expertise support your laboratory's success—contact us today to discuss your specific needs and discover how KINTEK can be your trusted partner in material science.

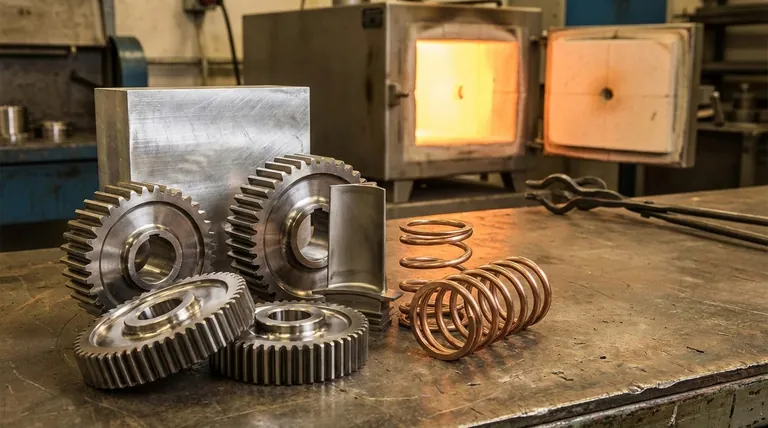

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

People Also Ask

- What equipment is used for heat treatment of steel? Choose the Right Furnace for Your Process

- What are the steps in vacuum brazing? Achieve Superior, Clean Metallurgical Bonds

- Why is a vacuum drying oven required after preparing mixed powders for TiC-steel composites? Ensure Material Purity

- Why is a laboratory vacuum oven used for the low-temperature drying of acid-functionalized nanoparticles?

- What is the purpose of using a vacuum drying oven for MIL-88B sensor materials? Preserve High-Porosity & Sensitivity

- What are industrial vacuum systems? A Guide to Boosting Efficiency in Material Handling & Processing

- Is annealing only for steel? Unlock Material Versatility with This Essential Heat Treatment

- What can brazing be used to join? Unlock Versatile Metal & Ceramic Bonding Solutions