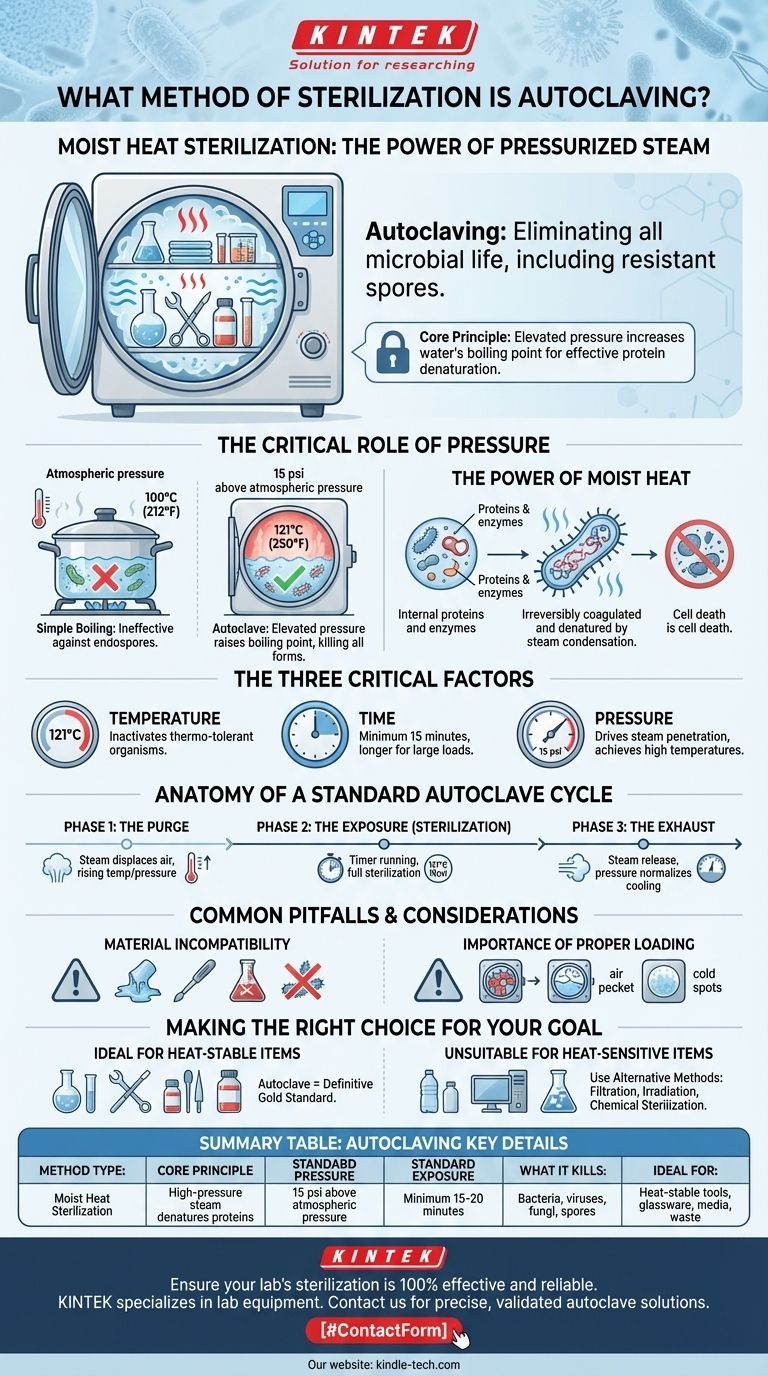

In essence, an autoclave is a device that performs sterilization using high-pressure, superheated steam. It is a specific and highly effective form of moist heat sterilization. This method is considered one of the most reliable for eliminating all forms of microbial life, including bacteria, viruses, fungi, and even highly resistant bacterial spores.

The core principle of autoclaving is not just about high heat; it's about using elevated pressure to increase the boiling point of water. This creates superheated, moisture-rich steam that can rapidly penetrate materials and destroy microorganisms by irreversibly damaging their essential proteins.

The Core Principle: Pressurized Steam as a Sterilizing Agent

Autoclaving leverages a fundamental principle of physics to achieve complete sterilization. The process is far more effective than simply boiling items in water.

Why Simple Boiling Is Not Enough

At standard atmospheric pressure, water boils at 100°C (212°F). While this temperature can kill many microbes, it is not sufficient to reliably destroy heat-resistant bacterial endospores.

The Critical Role of Pressure

An autoclave is a sealed chamber. By pumping steam into it and preventing it from escaping, the internal pressure increases significantly. This elevated pressure forces the boiling point of water to rise.

For example, at a pressure of approximately 15 psi (pounds per square inch) above atmospheric pressure, the boiling point of water increases to 121°C (250°F).

The Power of Moist Heat

The true effectiveness of autoclaving comes from the combination of high temperature and moisture. The steam condenses on cooler items placed inside, transferring heat energy with extreme efficiency.

This moist heat kills microorganisms by coagulating and denaturing their proteins and enzymes. This process is irreversible, effectively scrambling their internal structure and causing cell death.

The Three Critical Factors of Sterilization

Successful autoclaving depends on a precise balance of three interdependent factors. A failure in any one can lead to an incomplete sterilization cycle.

1. Temperature

A temperature of 121°C is a widely recognized standard for autoclaving. This temperature is high enough to inactivate the most thermo-tolerant organisms known.

2. Time

The high temperature must be maintained for a minimum duration to ensure the steam fully penetrates the entire load. A typical cycle holds the 121°C temperature for at least 15 minutes. Larger or denser loads may require longer exposure times.

3. Pressure

Pressure acts as the catalyst, enabling the steam to achieve the necessary high temperatures for sterilization. It also helps drive the steam into porous materials, ensuring no surface is left untouched.

Anatomy of a Standard Autoclave Cycle

A typical sterilization process in an autoclave consists of three distinct phases.

Phase 1: The Purge

Steam is introduced into the chamber, displacing the cooler, denser air by forcing it out. During this phase, both the temperature and pressure inside the chamber begin to ramp up toward the target setpoints.

Phase 2: The Exposure (Sterilization)

Once all the air has been removed and the chamber has reached the target temperature and pressure (e.g., 121°C at 15 psi), the cycle timer begins. The load is held under these conditions for the specified duration to ensure complete sterilization.

Phase 3: The Exhaust

The steam is slowly released from the chamber, and the pressure is returned to ambient levels. It is critical to release this pressure slowly when sterilizing liquids to prevent them from boiling over. The contents remain extremely hot even after the pressure is normalized.

Common Pitfalls and Considerations

While highly effective, autoclaving is not a universal solution, and improper use can lead to sterilization failure.

Material Incompatibility

The high heat and moisture make autoclaving unsuitable for heat-sensitive materials. This includes many plastics that can melt, sharp instruments that can be dulled, and substances that can be degraded by heat or moisture.

The Importance of Proper Loading

Overloading the autoclave or packing items too densely can create air pockets that prevent steam from reaching all surfaces. This is a common cause of sterilization failure, as trapped air creates "cold spots" that do not reach the required temperature.

Making the Right Choice for Your Goal

Selecting the correct sterilization method is critical for ensuring safety and material integrity.

- If your primary focus is sterilizing heat-resistant surgical tools, glassware, or biological culture media: The autoclave is the definitive gold standard for its unmatched reliability and ability to kill all microbial life.

- If your primary focus is sterilizing heat-sensitive items like certain plastics, electronics, or chemical solutions: You must use an alternative method such as filtration, irradiation, or chemical sterilization, as autoclaving would cause irreversible damage.

Ultimately, understanding that autoclaving is a precision method of moist heat sterilization is the key to using it effectively and safely.

Summary Table:

| Aspect | Key Detail |

|---|---|

| Method Type | Moist Heat Sterilization |

| Core Principle | High-pressure steam denatures microbial proteins |

| Standard Temperature | 121°C (250°F) |

| Standard Pressure | 15 psi above atmospheric pressure |

| Standard Exposure Time | Minimum 15-20 minutes |

| What It Kills | Bacteria, viruses, fungi, and bacterial spores |

| Ideal For | Heat-stable tools, glassware, media, and waste |

Ensure your lab's sterilization is 100% effective and reliable.

Autoclaving is a cornerstone of laboratory safety and integrity. Choosing the right autoclave for your specific needs is critical for protecting your research, samples, and personnel.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. Our experts can help you select the perfect autoclave solution that guarantees precise temperature control, uniform steam penetration, and complete sterilization cycle validation for your applications.

Contact us today to discuss your requirements and ensure your lab operates with the highest standards of safety and efficiency.

Visual Guide

Related Products

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Portable Digital Display Automatic Laboratory Sterilizer Lab Autoclave for Sterilization Pressure

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- How are autoclaves checked and maintained? Ensure Sterilization Safety and Compliance

- What kind of hazard can a lab personnel experienced in working with autoclave? Avoid Complacency with These Critical Risks

- What is autoclave in laboratory? Achieve Total Sterility for Your Lab

- What is the risk assessment for use of autoclave? Avoid Material Damage and Sterilization Failure

- What are the chambers of the autoclave? Understanding Single-Wall vs. Jacketed Designs