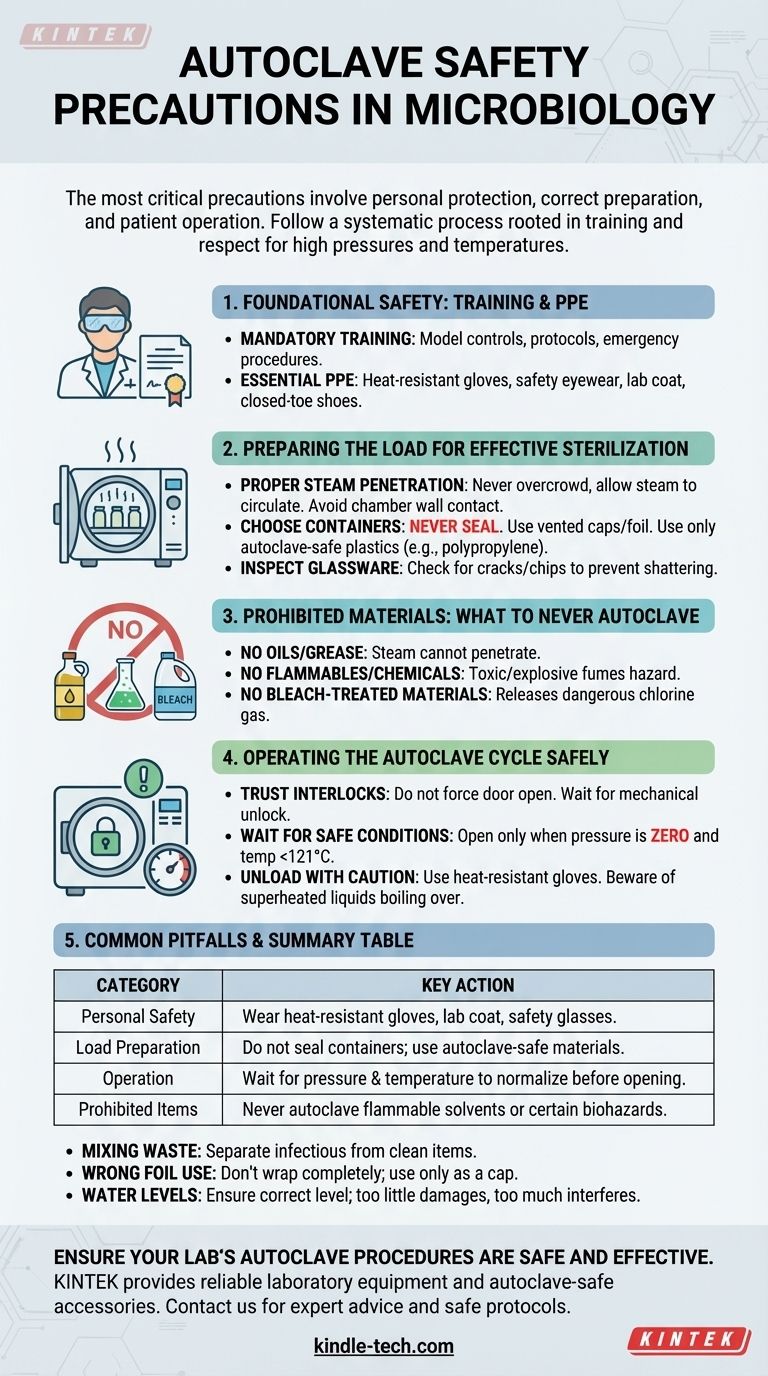

The most critical precautions for using an autoclave involve a combination of personal protection, correct material preparation, and patient operation. You must always wear appropriate Personal Protective Equipment (PPE), never seal containers being sterilized, ensure steam can circulate freely around all items, and wait until both pressure and temperature have returned to safe levels before opening the door.

The safe and effective use of an autoclave is not just about following a checklist for one cycle. It's about establishing a systematic process rooted in proper training, a deep understanding of what can and cannot be sterilized, and a respect for the high pressures and temperatures involved.

Foundational Safety: Training and PPE

Before you ever touch the machine, safety begins with knowledge and proper attire. This foundation prevents the most common and dangerous errors.

The Mandate for Proper Training

All users must be formally trained before operating an autoclave. A lack of knowledge is a significant safety risk.

This training should cover the specific model's controls, proper loading and unloading procedures, emergency protocols, and maintenance reporting.

Essential Personal Protective Equipment (PPE)

Your PPE is your first and last line of defense against burns and other injuries.

Always wear a lab coat, closed-toe shoes, protective eyewear, and a pair of heat-resistant, flame-retardant gloves for loading and, most importantly, for unloading hot items.

Preparing the Load for Effective Sterilization

How you prepare and load your materials directly impacts both safety and the success of the sterilization cycle. The goal is to allow steam to contact every surface.

Allow for Proper Steam Penetration

Never overcrowd the autoclave chamber. Items should be arranged neatly, allowing space between them for steam to circulate effectively.

Do not allow materials to touch the internal chamber walls. This can prevent proper sterilization and potentially damage the item or the autoclave.

Choose Appropriate Containers

Never seal a container. The extreme pressure change during a cycle will cause sealed glass containers to explode, creating a severe hazard. Cover containers with a steam-penetrable cap or use aluminum foil.

Avoid polyethylene trays, as they can melt at high temperatures and cause significant damage to the autoclave. Use only polypropylene or other autoclave-safe plastics.

Inspect Glassware for Integrity

Before loading, always inspect glassware for any cracks or chips. The intense pressure and temperature changes can easily cause compromised glassware to shatter during a cycle.

Prohibited Materials: What to Never Autoclave

Understanding what not to put in an autoclave is as important as knowing what to put in. Certain materials can damage the machine or release hazardous substances.

Avoid Non-Porous and Reactive Substances

Do not autoclave waterproof or non-porous materials like oils and grease, as steam cannot penetrate them to achieve sterilization.

Never autoclave flammable solvents or hazardous chemicals. Heating these substances can create toxic or explosive fumes. Similarly, do not autoclave materials that have been treated with bleach, as this can release chlorine gas.

Do Not Autoclave Certain Biohazards

Low molecular weight biotoxins, certain pathogenic wastes, and sharp materials should not be autoclaved without specific institutional protocols. These often require alternative decontamination methods.

Operating the Autoclave Cycle Safely

Patience and adherence to the machine's designed safety features are paramount during and after the sterilization cycle.

Trust the Machine's Safety Interlocks

Do not attempt to open the door while the autoclave is running. Modern autoclaves have mechanical locks that only disengage once the pressure has normalized. Forcing the door can damage the mechanism and pose an extreme safety hazard.

If you suspect an issue, use the controller or emergency stop to abort the cycle. Wait for the chamber to completely depressurize and cool before attempting to open the door.

Wait for Safe Conditions Before Opening

After a cycle completes, you must wait for two conditions to be met: the chamber pressure must return to zero, and the internal temperature should be at or below 121°C.

Open the door slowly and stand back to allow any residual steam to escape safely, protecting your face and body from potential steam burns.

Unload with Caution

Handle all items with heat-resistant gloves. Be especially careful with liquids, as they can be superheated and may boil over violently if agitated.

Common Pitfalls to Avoid

Even experienced users can make mistakes. Being aware of these common errors helps reinforce safe habits.

Mixing Waste and Clean Items

Always autoclave infectious waste separately from clean items intended for reuse. This prevents cross-contamination and ensures proper biohazard handling protocols are followed.

Using Aluminum Foil Incorrectly

While foil can be used to cap flasks, you should never wrap an object completely in foil. This practice acts as a barrier that prevents steam from reaching the surfaces you intend to sterilize.

Mismanaging Water Levels

Ensure the correct amount of water is present in the autoclave before starting a cycle. Too little water can damage the heating elements, while too much can interfere with proper operation.

Making the Right Choice for Your Goal

Your approach to autoclaving should be guided by your primary objective, whether it's personal safety or process reliability.

- If your primary focus is personal safety: Prioritize comprehensive training and the consistent use of all required PPE, especially heat-resistant gloves and eyewear during unloading.

- If your primary focus is guaranteed sterilization efficacy: Concentrate on proper loading techniques that maximize steam penetration and strictly avoid prohibited or incompatible materials.

- If your primary focus is establishing a safe lab protocol: Implement a mandatory training program, post clear operating instructions at the machine, and conduct regular monitoring to ensure compliance and effectiveness.

Adhering to these precautions transforms the autoclave from a potential hazard into an indispensable tool for reliable and reproducible science.

Summary Table:

| Precaution Category | Key Action | Why It's Important |

|---|---|---|

| Personal Safety | Wear heat-resistant gloves, lab coat, safety glasses. | Protects against steam burns and shattering glass. |

| Load Preparation | Do not seal containers; use autoclave-safe materials. | Prevents explosions and allows steam penetration for sterilization. |

| Operation | Wait for pressure & temperature to normalize before opening. | Prevents violent steam release and potential injury. |

| Prohibited Items | Never autoclave flammable solvents or certain biohazards. | Avoids toxic fume release and damage to equipment. |

Ensure your lab's autoclave procedures are safe and effective. KINTEK specializes in providing reliable laboratory equipment and consumables, including autoclaves and autoclave-safe accessories. Our experts can help you select the right equipment and establish safe protocols for your specific microbiology needs. Contact us today to enhance your lab's sterilization safety and efficiency!

Visual Guide

Related Products

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- Why is an autoclave set to 121°C for sterilization? The Science Behind Guaranteed Sterility

- Why is a laboratory autoclave necessary for carbohydrate composition analysis? Unlock Accurate Sugar Yields

- How do you calculate autoclave capacity? Avoid Sterilization Failures with the Right Formula

- What are the 5 types of autoclave? The 3 Key Classes That Define Sterilization Safety

- What is the temperature above 100 for autoclaving? Achieve Sterilization at 121°C

- Why is an Autoclave essential for simulating nuclear reactor conditions during the corrosion testing of zirconium alloys?

- Which instruments are sterilized in autoclave? Ensure Sterility for Your Lab Equipment

- What is the primary purpose of mini-autoclaves in supercritical water corrosion? Ensure Data Integrity with KINTEK