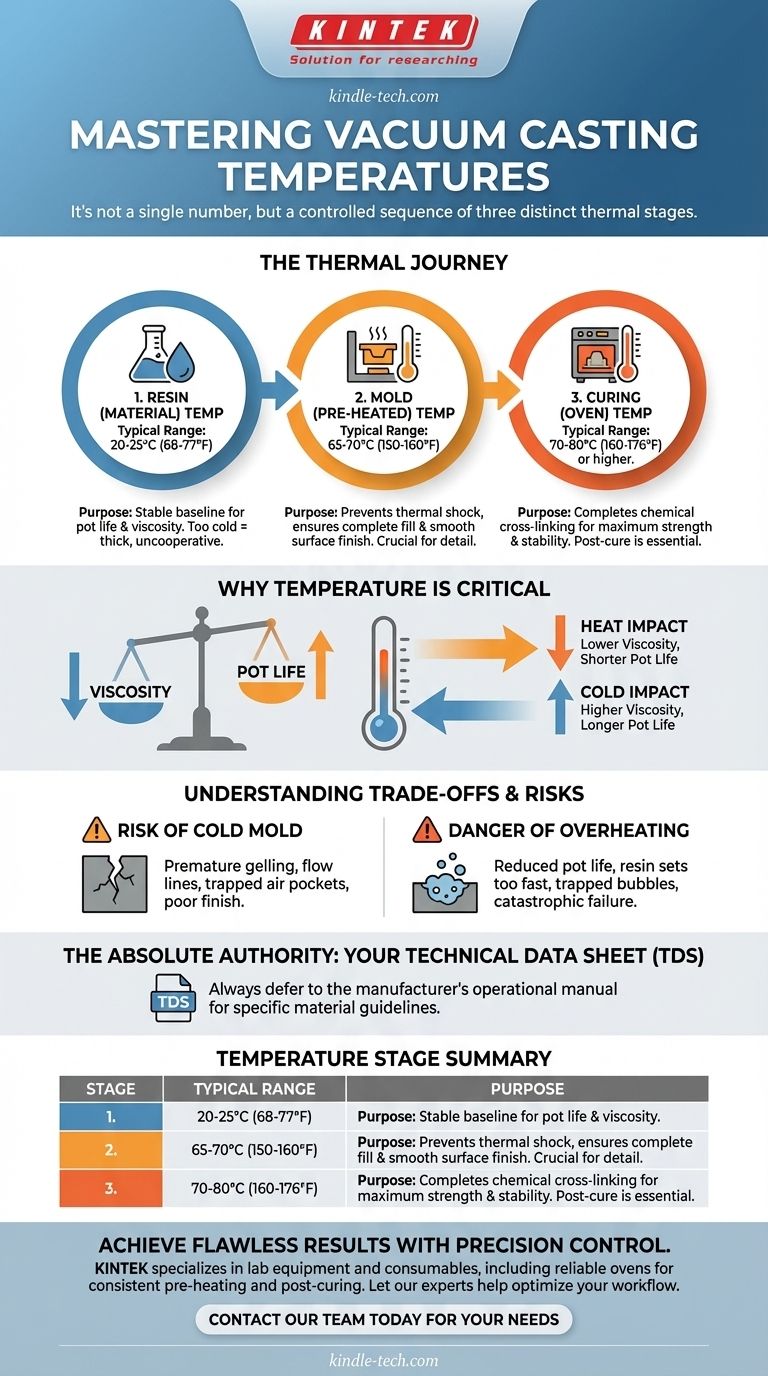

The ideal temperature for vacuum casting is not a single number but a carefully controlled sequence of three distinct temperatures. These are the temperature of the mixed resin (typically room temperature, ~25°C or 77°F), the pre-heated silicone mold (usually 65-70°C or 150-160°F), and the final curing oven temperature (often 70°C or 160°F or higher), each dictated by the material's specific Technical Data Sheet (TDS).

Successful vacuum casting has less to do with finding one perfect temperature and more to do with mastering the thermal relationship between your material, your mold, and your curing process. Each stage has its own thermal requirement that directly impacts the final quality of the part.

Why Temperature is the Most Critical Variable

In vacuum casting, temperature governs the two most important properties of your liquid resin: its viscosity and its pot life.

Viscosity is a measure of how easily a fluid flows. Pot life is the working time you have before the mixed resin begins to gel and solidify. Controlling temperature gives you direct control over both.

The Impact of Heat

A warmer temperature lowers the resin's viscosity, making it flow more easily into fine details. However, it also accelerates the chemical reaction, drastically shortening the pot life.

The Impact of Cold

A cooler temperature extends the pot life, giving you more time to work. But it also increases the resin's viscosity, making it thicker and potentially preventing it from filling all the small features of your mold.

The Three Key Temperatures to Master

A successful casting process relies on managing a thermal journey. You are not holding one temperature; you are transitioning the material through three critical thermal stages.

1. The Material (Resin) Temperature

The two components of the casting resin (typically a polyurethane) are almost always stored and mixed at a standard room temperature, around 20-25°C (68-77°F).

This provides a stable, predictable baseline for the material's stated pot life. Mixing a resin that is too cold will result in a thick, uncooperative consistency.

2. The Mold Temperature

The silicone mold must be pre-heated before casting. A typical pre-heat temperature is 65-70°C (150-160°F).

The primary goal of pre-heating is to prevent "thermal shock." Pouring warm, reacting resin into a cold mold would cause the resin to cool where it touches the mold wall, increasing its viscosity and leading to flow marks, incomplete fills, and poor surface finish. A hot mold ensures the resin remains fluid as it fills the cavity.

3. The Curing Temperature

After the part has been de-molded, it is not yet at its full strength. It must be post-cured in an oven at a specific temperature for several hours.

This final heating stage, often around 70-80°C (160-176°F) or higher, completes the chemical cross-linking within the polymer. Skipping this step will result in a part that is weak, brittle, and dimensionally unstable.

Understanding the Trade-offs

Deviating from the recommended temperature profile for your material introduces significant risk. The manufacturer's Technical Data Sheet (TDS) is your single source of truth.

The Risk of a Cold Mold

Using a mold that is not properly pre-heated is a common cause of failure. It can lead to flow lines, trapped air pockets, and a poor surface finish as the resin gels prematurely upon contact with the cold silicone.

The Danger of an Overheated Mold or Resin

Overheating the mold or mixing resin that is too warm can be just as catastrophic. It can reduce the pot life so much that the resin begins to set before the vacuum chamber has fully evacuated the air, trapping a mass of bubbles within your part.

The Absolute Authority: Your Technical Data Sheet (TDS)

Every casting resin is a unique chemical formulation. The TDS provided by the manufacturer is not a suggestion; it is the operational manual for that specific material. It will explicitly state the recommended mold temperature, pot life at a given mass, and the precise time and temperature for post-curing. Always defer to the TDS.

Making the Right Choice for Your Goal

Your primary guide should always be the material's TDS. However, slight, expert adjustments can be made to optimize for specific outcomes.

- If your primary focus is capturing extremely fine detail: Ensure your mold is fully and evenly pre-heated to the upper end of the recommended range to maximize resin fluidity.

- If your primary focus is casting a very large or thick part: You might consider mixing your resin in a slightly cooler environment to gain precious seconds of pot life, but never let the mold itself get cold.

- If your primary focus is achieving maximum mechanical strength: Do not deviate from the post-curing schedule. Follow the time and temperature recommendations from the TDS exactly to ensure the material achieves its full datasheet properties.

Ultimately, mastering these temperatures is the key to transforming your casting process from guesswork into a reliable, repeatable science.

Summary Table:

| Temperature Stage | Typical Range | Purpose |

|---|---|---|

| Resin (Material) | 20-25°C (68-77°F) | Provides stable baseline for pot life and viscosity |

| Mold (Pre-heated) | 65-70°C (150-160°F) | Prevents thermal shock, ensures complete fill and smooth finish |

| Curing (Oven) | 70-80°C (160-176°F) or higher | Completes chemical reaction for maximum strength and stability |

Achieve flawless vacuum casting results with precision temperature control. Mastering the thermal profile is essential for part quality, from fine detail reproduction to mechanical strength. KINTEK specializes in the lab equipment and consumables that support your entire casting process, including reliable ovens for consistent mold pre-heating and post-curing. Let our experts help you optimize your workflow for repeatable, high-quality outcomes. Contact our team today to discuss your specific vacuum casting needs.

Visual Guide

Related Products

- Special Shape Press Mold for Lab

- Polygon Press Mold for Lab

- Ball Press Mold for Lab

- Cylindrical Press Mold with Scale for Lab

- Round Bidirectional Press Mold for Lab

People Also Ask

- What technical requirements must specialized pressure-bearing molds meet? Optimize Sulfide Electrolyte Densification

- What role do customized metal molds play in solid-state battery densification? Achieving Precision at 500 MPa

- How does a stainless steel pressure die ensure the quality of the electrolyte layer? Unlock Precision Battery Assembly

- What functions do high-purity graphite molds serve for IZO targets? Ensure Density and Prevent Sintering Cracks

- What technical characteristics are required for specialty pressure molds used in the compaction of Li10GeP2S12? Expert Tips