For optimal results in IR spectroscopy, the standard and safest temperature for drying Potassium Bromide (KBr) is between 105 °C and 110 °C. This process should be carried out for a minimum of 4 hours, though an overnight duration in a vacuum oven is the most common laboratory practice to ensure all adsorbed water is removed.

The core objective of drying KBr is to eliminate the strong, interfering infrared absorption bands of water. Failing to properly dry the KBr will introduce significant artifacts into your spectrum, potentially masking the true spectral features of your sample and leading to incorrect data interpretation.

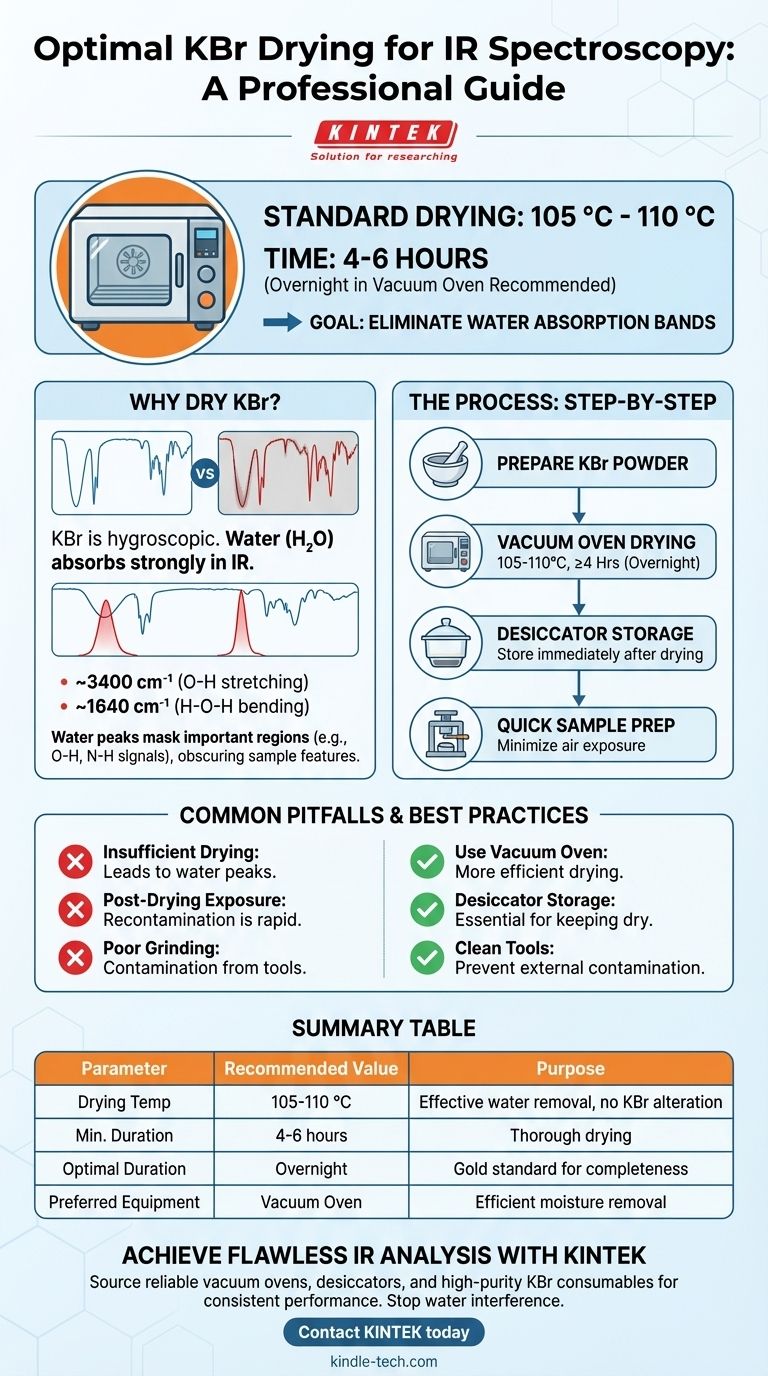

Why Drying KBr is Critical for IR Analysis

Potassium Bromide is the most common matrix material for solid-sample IR spectroscopy because it is transparent to IR radiation across a wide range. However, its primary drawback is its hygroscopic nature, meaning it readily absorbs moisture from the atmosphere.

The Problem of Water Contamination

Water (H₂O) is a very strong infrared absorber. Even trace amounts of moisture in your KBr will produce two distinct, characteristic absorption bands in your spectrum:

- A very broad, strong peak around 3400 cm⁻¹ due to the O-H stretching vibration.

- A sharp, medium-intensity peak around 1640 cm⁻¹ due to the H-O-H bending vibration.

Impact on Spectral Quality

These water peaks can completely obscure important regions of the spectrum. For example, the broad 3400 cm⁻¹ peak can easily mask the N-H stretching vibrations from amines and amides or the O-H signals from alcohols and carboxylic acids in your actual sample, making analysis impossible.

The Standard Drying Protocol

Achieving a moisture-free KBr matrix is straightforward if a consistent protocol is followed. The key is balancing temperature and time to drive off water without altering the KBr itself.

Recommended Temperature and Duration

The ideal temperature range is 105-110 °C. This is safely above the boiling point of water (100 °C), ensuring effective removal, but well below the melting point of KBr (~734 °C), preventing any risk of sintering or melting the powder.

Drying for at least 4-6 hours is recommended, with overnight being the gold standard for ensuring complete dryness.

The Role of a Vacuum Oven

Using a vacuum oven is highly preferred. The vacuum lowers the effective boiling point of water and actively pulls moisture vapor away from the KBr powder, resulting in a more thorough and efficient drying process compared to a standard convection oven.

Common Pitfalls and Best Practices

Simply drying the KBr is only half the battle. Proper handling after drying is essential to prevent recontamination.

Insufficient Drying

If you cut the drying time short or use too low a temperature, you will fail to remove all the adsorbed water. You will immediately see the characteristic water peaks in your background scan or sample spectrum.

Post-Drying Contamination

Once dried, KBr is extremely hygroscopic and will begin absorbing atmospheric moisture immediately.

- Always store dried KBr powder in a sealed container inside a desiccator.

- When preparing your sample pellet, work as quickly and efficiently as possible to minimize the KBr’s exposure time to ambient air.

Poor Grinding Technique

When grinding your sample with the dried KBr, ensure both the mortar and pestle are perfectly clean and dry. Any residual moisture or cleaning solvent on your tools will contaminate the mixture you just worked so hard to prepare.

Making the Right Choice for Your Goal

Your analytical goal dictates how meticulously you must follow this procedure.

- If your primary focus is on the "fingerprint" region (below 1500 cm⁻¹): While still crucial, minor moisture contamination is less likely to interfere directly with C-C, C-O, or C-X bond vibrations.

- If your primary focus is identifying O-H or N-H functional groups: Meticulous drying and handling are non-negotiable. Even trace water signals can create false positives or mask the subtle features of your analyte.

- If you are performing quantitative analysis: An absolutely clean, dry, and reproducible background is essential, making the full overnight vacuum oven protocol the only reliable option.

Ultimately, proper KBr preparation is the foundation of trustworthy and reproducible spectroscopic results.

Summary Table:

| Parameter | Recommended Value | Purpose |

|---|---|---|

| Drying Temperature | 105 - 110 °C | Effectively removes water without altering KBr. |

| Minimum Duration | 4-6 hours | Ensures thorough drying. |

| Optimal Duration | Overnight | Gold standard for complete moisture removal. |

| Preferred Equipment | Vacuum Oven | Lowers water's boiling point for more efficient drying. |

Achieve Flawless IR Analysis with KINTEK

Eliminating moisture interference is critical for accurate IR spectroscopy. Properly dried KBr is the foundation of reliable results. KINTEK specializes in providing the high-quality lab equipment and consumables you need to perfect your sample preparation.

We can help you:

- Source reliable vacuum ovens for efficient KBr drying.

- Find the right desiccators and storage solutions to keep your dried KBr contamination-free.

- Access high-purity KBr powders and consumables for consistent performance.

Stop letting water peaks obscure your data. Let our experts support your laboratory's success.

Contact KINTEK today to discuss your specific lab equipment needs!

Visual Guide

Related Products

- Laboratory Scientific Electric Heating Blast Drying Oven

- 1200℃ Muffle Furnace Oven for Laboratory

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- Large Vertical Graphite Vacuum Graphitization Furnace

People Also Ask

- What role does a laboratory drying oven play in the processing and chemical analysis of aluminum dross?

- How does a laboratory constant temperature drying oven contribute to the processing of synthesized Zinc Oxide precipitates?

- What is the primary purpose of using an electric drying oven for dense refractory bricks? Optimize Raw Material Prep

- What is the function of a laboratory oven in W18Cr4V steel sample preparation? Expert Microstructural Drying Guide

- How does a controlled drying process ensure the quality of radiochromic films? Achieve Precise Dosimetric Results