THC (tetrahydrocannabinol), the primary psychoactive compound in cannabis, undergoes sublimation under specific conditions. Sublimation refers to the transition of a substance directly from a solid to a gas without passing through the liquid phase. Based on the provided reference, THC begins to evaporate at 157°C under atmospheric pressure. This temperature is critical for understanding the thermal stability and behavior of THC during processes like vaporization or extraction. Below, I will break down the key points related to THC sublimation and its implications.

Key Points Explained:

-

Definition of Sublimation and Its Relevance to THC

- Sublimation is the process where a solid transitions directly into a gas without becoming a liquid.

- For THC, sublimation occurs at specific temperatures, making it relevant for applications like vaporization, where THC is heated to produce inhalable vapor.

-

THC Sublimation Temperature

- According to the reference, THC begins to evaporate at 157°C under atmospheric pressure.

- This temperature is a critical threshold for ensuring efficient vaporization without degrading the compound.

-

Factors Influencing THC Sublimation

- Pressure: Atmospheric pressure is a key factor. Changes in pressure can alter the sublimation temperature.

- Purity of THC: Impurities or the presence of other cannabinoids (like CBD) can affect the sublimation process.

- Heating Method: Consistent and controlled heating is essential to avoid overheating, which can degrade THC into less desirable compounds.

-

Comparison with CBD

- The reference notes that CBD (cannabidiol) evaporates at a higher temperature range of 160–180°C.

- This difference in sublimation temperatures allows for selective extraction or vaporization of THC and CBD, depending on the desired application.

-

Practical Implications for Equipment and Consumables

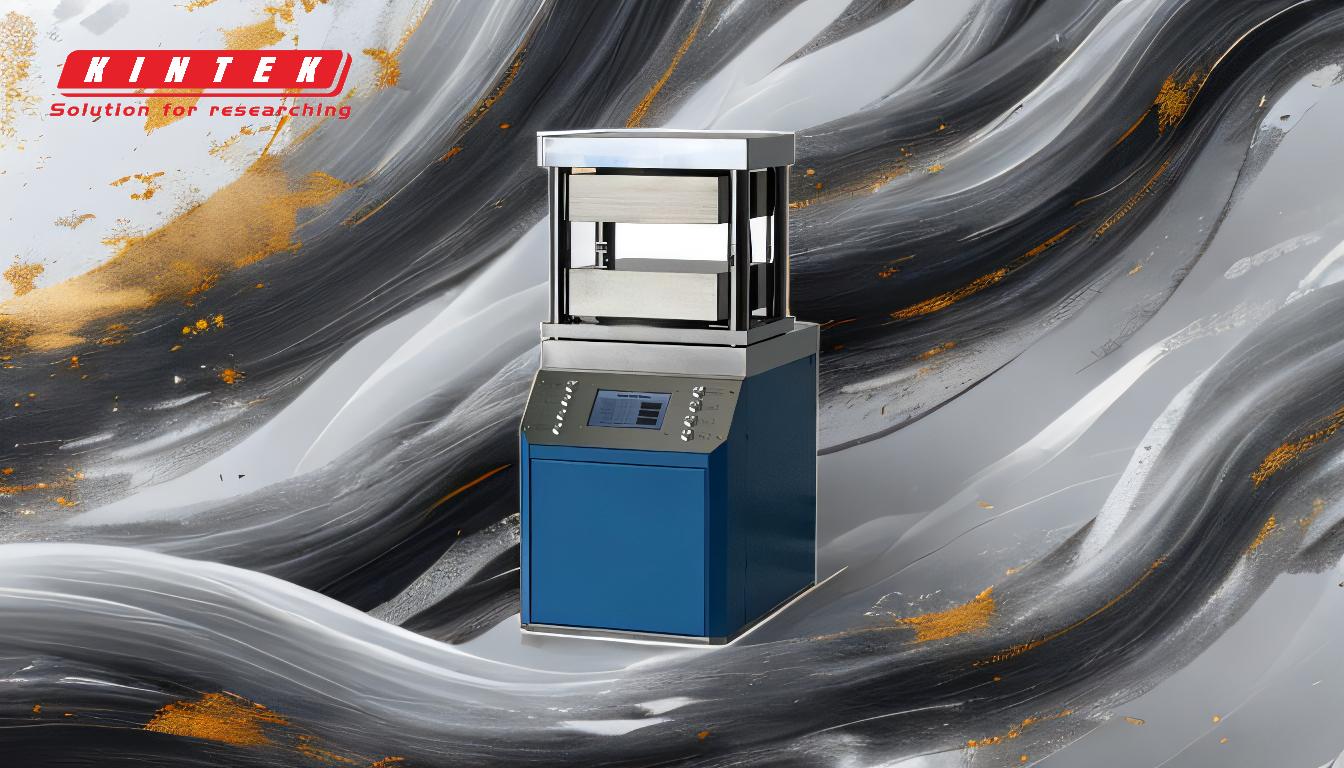

- Vaporizers: Devices designed for THC vaporization must maintain precise temperature control to ensure efficient sublimation without combustion.

- Extraction Equipment: Sublimation temperatures are critical for processes like distillation, where THC is separated from other compounds.

- Consumables: Understanding sublimation helps in selecting appropriate materials for storage and handling to prevent unintended evaporation.

-

Importance of Temperature Control

- Exceeding the sublimation temperature can lead to degradation of THC into other compounds, reducing its potency and efficacy.

- Maintaining temperatures just above 157°C ensures optimal vaporization without risking degradation.

-

Applications in Cannabis Industry

- Medical Use: Precise sublimation temperatures are crucial for producing consistent and effective medical cannabis products.

- Recreational Use: Vaporizers and other devices rely on accurate temperature settings to deliver a satisfying user experience.

- Research and Development: Understanding sublimation aids in developing new methods for cannabinoid extraction and purification.

In conclusion, THC sublimates at 157°C under atmospheric pressure, a critical temperature for various applications in the cannabis industry. By understanding this process and its influencing factors, equipment and consumable purchasers can make informed decisions to optimize performance and ensure product quality.

Summary Table:

| Key Aspect | Details |

|---|---|

| THC Sublimation Temperature | 157°C under atmospheric pressure |

| Factors Influencing Sublimation | Pressure, THC purity, heating method |

| Comparison with CBD | CBD evaporates at 160–180°C |

| Applications | Vaporizers, extraction equipment, medical/recreational cannabis products |

| Importance of Temperature Control | Prevents THC degradation, ensures optimal vaporization |

Need precise temperature control for THC applications? Contact our experts today to optimize your process!