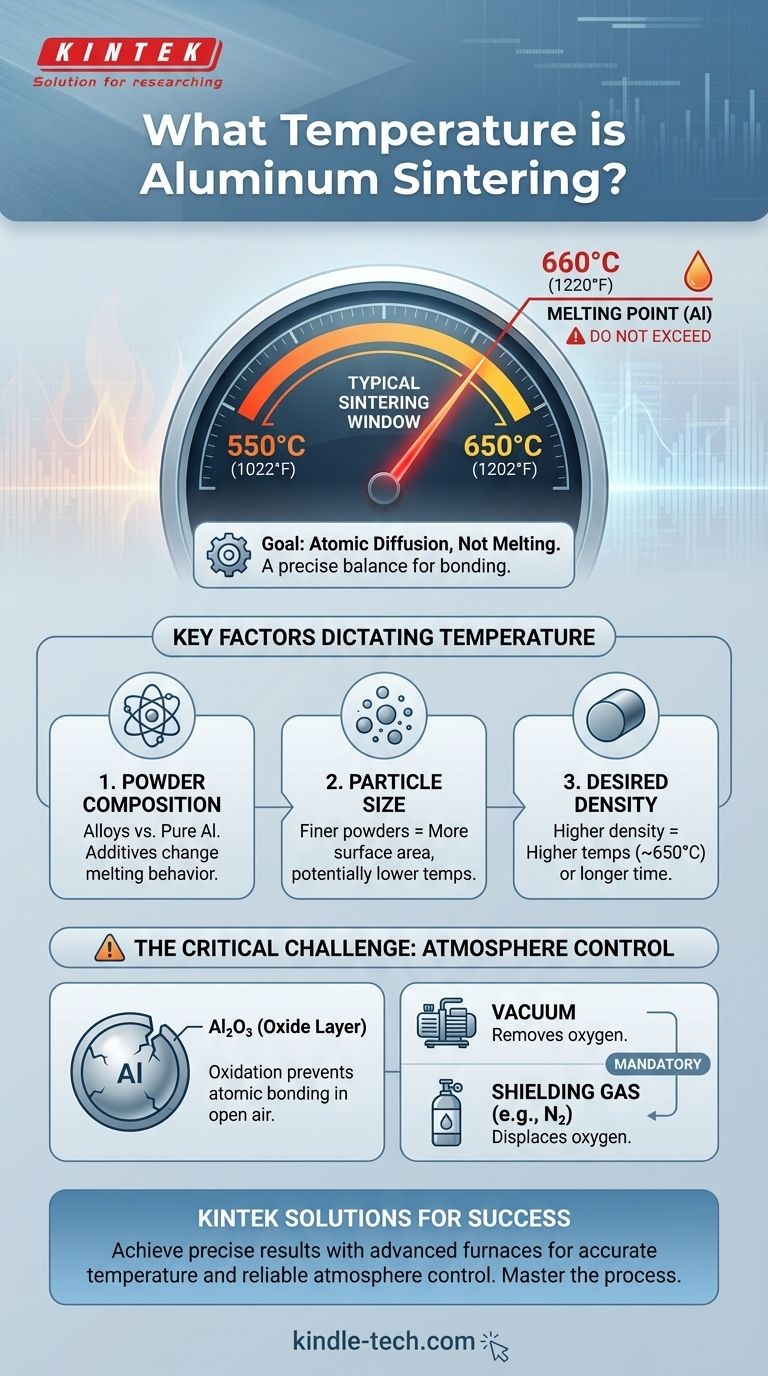

The typical sintering temperature for aluminum falls within a precise window of approximately 550°C to 650°C (1022°F to 1202°F). This temperature is intentionally kept just below aluminum's melting point of 660°C. The exact temperature required is not a fixed number but is highly dependent on the specific characteristics of the aluminum powder and the desired properties of the final component.

Successful aluminum sintering is less about hitting a single magic number and more about carefully managing the relationship between temperature, material properties, and atmospheric conditions to achieve atomic bonding without melting.

The Science of Aluminum Sintering

Sintering is a thermal process that fuses powder particles into a solid mass using heat, but without melting the material into a liquid state. This is crucial for creating parts with specific porosity or near-net shapes directly from powder.

The Goal: Atomic Diffusion

The heat applied during sintering gives the atoms within the aluminum particles enough energy to move. This movement, known as atomic diffusion, allows atoms to migrate across the boundaries of adjacent particles, forming strong metallic bonds and fusing the powder together.

Why Temperature Varies

The ideal sintering temperature is a function of several variables. Simply setting a furnace to a generic temperature without considering these factors will lead to inconsistent and unreliable results.

Key Factors That Dictate Sintering Temperature

To achieve the desired outcome, you must adjust the temperature based on the unique properties of your starting material and your end goal.

Powder Composition

Pure aluminum sinters differently than aluminum alloys. The addition of other elements (like copper, magnesium, or silicon) changes the material's melting behavior and the rate of diffusion, requiring adjustments to the sintering temperature.

Particle Size and Distribution

Powders with smaller particles have a much higher surface-area-to-volume ratio. This increased surface area provides more pathways for atomic diffusion, often allowing for effective sintering at the lower end of the temperature range or for shorter cycle times.

Desired Degree of Sintering

The final density and strength required for the component directly influence the process. Achieving a higher density typically requires operating at the higher end of the temperature range (closer to 650°C) or holding the temperature for a longer period to allow for more complete diffusion.

Common Pitfalls and Critical Considerations

Temperature is only one part of the equation. For a metal as reactive as aluminum, the processing atmosphere is just as critical.

The Oxidation Challenge

Aluminum instantly reacts with oxygen in the air to form a very thin but extremely tough and stable layer of aluminum oxide (Al₂O₃). This oxide layer has a much higher melting point than aluminum itself and acts as a barrier, preventing the direct metal-to-metal contact necessary for atomic diffusion.

The Absolute Need for a Controlled Atmosphere

To overcome the oxidation problem, aluminum sintering must be performed in a controlled atmosphere. Attempting to sinter aluminum in open air will fail.

The two primary methods are:

- Vacuum: Performing the process in a vacuum furnace removes the oxygen, preventing the oxide layer from forming.

- Shielding Gas: Using an inert or specific shielding gas (like nitrogen or an endothermic gas) displaces the oxygen, protecting the aluminum particles as they are heated.

How to Apply This to Your Project

Your specific goal will determine your approach to the sintering process.

- If your primary focus is achieving maximum part density: Plan to operate at the higher end of the 550°C to 650°C range and ensure you are using a high-quality vacuum or a pure, dry shielding gas.

- If your primary focus is working with a specific aluminum alloy: You must obtain the technical data sheet for that specific alloy, as its ideal sintering window may be significantly different from that of pure aluminum.

- If your primary focus is process efficiency: Carefully analyze the trade-off between particle size, temperature, and time. Finer powders may allow for slightly lower temperatures or shorter cycles, but are often more expensive.

Ultimately, successful aluminum sintering is a precise balancing act between temperature, time, material characteristics, and atmospheric control.

Summary Table:

| Factor | Impact on Sintering Temperature |

|---|---|

| Powder Composition | Alloys require different temperatures than pure aluminum. |

| Particle Size | Finer powders may allow for sintering at lower temperatures. |

| Desired Density | Higher density parts need temperatures at the higher end of the range (~650°C). |

| Atmosphere Control | Critical for success; vacuum or shielding gas is mandatory to prevent oxidation. |

Achieve precise and reliable aluminum sintering results.

Navigating the precise temperature window and critical atmosphere controls for aluminum sintering is complex. KINTEK specializes in providing the advanced lab furnaces and expert support you need to master this process.

Our sintering furnaces offer the precise temperature control and reliable vacuum or gas atmospheres required to successfully bond aluminum powders without melting or oxidation. Whether you are working on R&D or production, we provide the equipment and consumables to ensure your success.

Contact us today to discuss your specific aluminum sintering requirements and how our solutions can enhance your lab's capabilities and efficiency. Get in touch with our experts now!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Molybdenum Vacuum Heat Treat Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is vacuum furnace high temperature? Unlock the Range for Your Material Processing

- Is heat Cannot travel in a vacuum True or false? Discover How Heat Crosses the Void of Space

- What are the advantages of a vacuum furnace? Achieve Superior Purity and Control in Heat Treatment

- What is the standard thickness of plating? Optimize Durability, Corrosion & Cost

- What is the maximum temperature in a vacuum furnace? It Depends on Your Materials and Process Needs