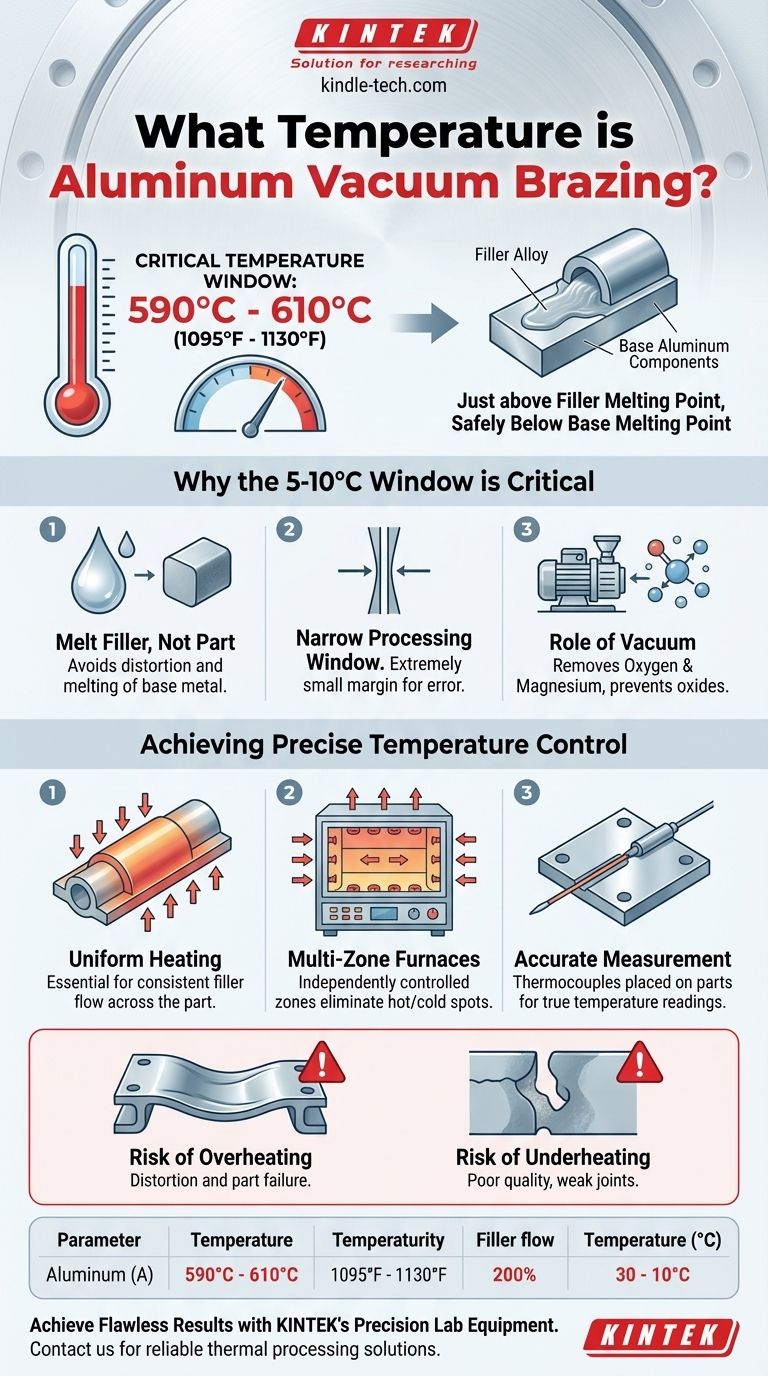

In short, aluminum vacuum brazing typically occurs in a very narrow temperature range, generally between 590°C and 610°C (1095°F to 1130°F). This precise temperature is chosen to be just above the melting point of the filler alloy but safely below the melting point of the aluminum components being joined.

The central challenge of aluminum vacuum brazing is not merely reaching a specific temperature, but maintaining absolute uniformity across the entire part within an extremely tight window. Success depends on melting the filler material without distorting or melting the base aluminum itself.

Why This Specific Temperature Window is Critical

The entire process of brazing relies on a carefully controlled thermal gap between the filler metal and the base metal. For aluminum, this gap is notoriously small, making precision paramount.

Melting the Filler, Not the Part

Brazing works by melting a filler material (the brazing alloy) that flows into the joints between two or more base components via capillary action.

The temperature must be high enough to make the filler alloy fully liquid, allowing it to flow freely and create a strong metallurgical bond upon cooling.

Crucially, this temperature must remain below the "solidus" temperature of the base aluminum, which is the point where the base metal itself begins to melt.

The Narrow Processing Window

The brazing temperature is strategically set between the filler's liquidus (the temperature at which it becomes fully liquid) and the base metal's solidus.

For common aluminum brazing setups (e.g., using an AA4047 aluminum-silicon filler), this operational window can be as narrow as 5-10°C. This leaves almost no room for error.

The Role of the Vacuum

Operating at these high temperatures in a vacuum environment serves two primary functions.

First, it removes oxygen, preventing the formation of aluminum oxides that would otherwise block the filler material from wetting the surface and forming a bond.

Second, it removes magnesium, an alloying element in many aluminum grades that vaporizes at brazing temperatures. If not removed by the vacuum, this magnesium vapor would interfere with the brazing process.

Achieving Precise Temperature Control

As the reference material highlights, achieving the correct temperature is worthless if it isn't uniform. A temperature difference of just a few degrees across the part can lead to total failure.

The Need for Uniform Heating

If one area of the assembly is hotter than another, a thin section might melt before a thicker section even reaches the required brazing temperature.

This uniformity ensures that the filler material activates and flows evenly across all joints at the same time.

Multi-Zone Furnaces

Modern vacuum furnaces achieve this uniformity by using multiple, independently controlled heating zones.

These zones surround the parts, and sophisticated control systems adjust the power to each zone to eliminate hot or cold spots, ensuring the entire assembly heats and cools at a consistent rate.

Accurate Temperature Measurement

To control the process, thermocouples are placed strategically on or near the parts themselves, not just in the general furnace chamber.

This provides a true reading of the part temperature, allowing the control system to maintain the heating element temperature as close as possible to the target without overheating the part's surface.

Understanding the Trade-offs and Risks

The narrow processing window for aluminum brazing introduces significant risks that must be managed through precise process control.

Risk of Overheating

Exceeding the solidus temperature of the base metal, even for a short time, will cause the parts to distort, sag, or melt. This is a catastrophic failure that results in a scrapped part.

Risk of Underheating

Failing to reach the liquidus temperature of the filler alloy will result in a poor-quality joint. The filler will not flow correctly, leading to voids, incomplete bonds ("no-fills"), and a structurally unreliable final product.

Complications from Part Geometry

Assemblies with both very thick and very thin sections are especially challenging. The thin sections heat up much faster, increasing the risk of overheating them while waiting for the thick sections to reach the target temperature. This requires a carefully programmed and often slower heating cycle.

Making the Right Choice for Your Goal

Successfully brazing aluminum is less about a single temperature number and more about flawlessly executing a complete thermal profile.

- If your primary focus is process reliability: Invest in a modern, multi-zone vacuum furnace with precise thermocouple-based controls to guarantee temperature uniformity.

- If your primary focus is joint quality: Ensure your chosen filler alloy and base alloy are compatible, providing a workable (even if narrow) temperature window.

- If your primary focus is part design: Design parts with uniform thickness where possible, as this simplifies the heating process and dramatically reduces the risk of failure.

Ultimately, precision is the non-negotiable principle that governs every successful aluminum vacuum brazing operation.

Summary Table:

| Parameter | Typical Range | Critical Consideration |

|---|---|---|

| Brazing Temperature | 590°C - 610°C (1095°F - 1130°F) | Must stay above filler liquidus, below base metal solidus |

| Temperature Window | 5-10°C (narrow) | Requires precise furnace control |

| Key Challenge | Uniform heating across parts | Prevents distortion and ensures complete filler flow |

| Common Filler Alloy | AA4047 (Aluminum-Silicon) | Provides optimal melting characteristics for base aluminum |

Achieve flawless aluminum brazing results with KINTEK's precision lab equipment. Our advanced vacuum furnaces feature multi-zone heating and precise temperature controls specifically designed for challenging processes like aluminum brazing. We serve laboratories and manufacturing facilities requiring reliable thermal processing solutions.

Contact us today to discuss how our equipment can help you maintain the critical temperature uniformity needed for successful aluminum vacuum brazing operations.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

People Also Ask

- How is brazing different from soldering? A Guide to Stronger vs. Softer Joining

- How does a vacuum sintering furnace facilitate MgO densification? Optimize Purity and Density with KINTEK Solutions

- What is the necessity of using a vacuum drying oven for metal powders? Ensure Purity & Prevent Oxidation

- How does the vacuum pump system influence magnesium morphology? Control Pressure for High-Purity Crystallization

- What is the pressure in a pyrolysis reactor? A Guide to Optimizing Your Process

- What is the use of vacuum coating? Engineer Superior Surface Properties for Your Products

- Why is a vacuum drying oven required for epoxy curing agents? Prevent Bubbles & Ensure Chemical Purity

- How is a temperature-programmed furnace with a high-vacuum system utilized in the preparation of H-type zeolite catalysts?