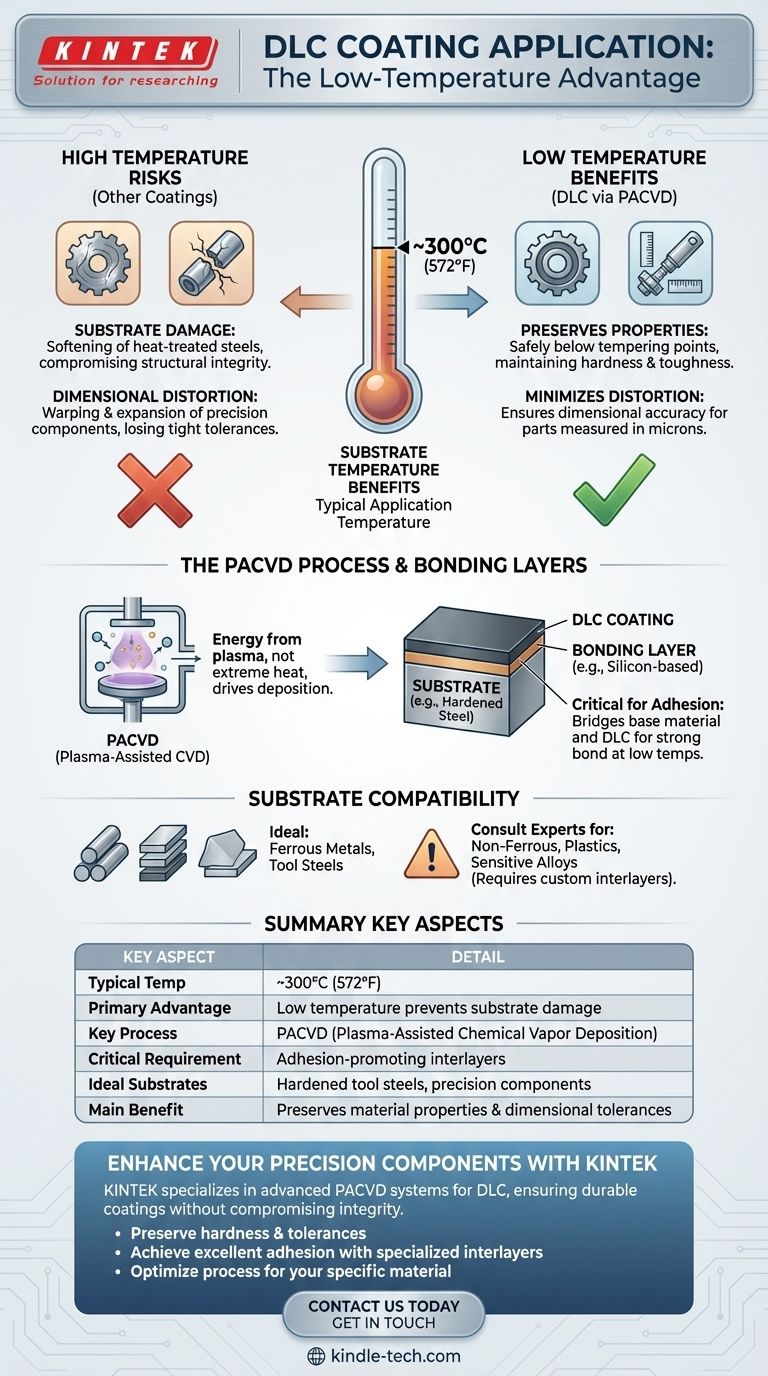

In practice, Diamond-Like Carbon (DLC) coatings are applied at relatively low temperatures, typically around 300°C (572°F). This is a key advantage of the process, but this temperature is only achievable with excellent adhesion when specific bonding layers are used to prepare the substrate material.

The core takeaway is that DLC is considered a "low-temperature" coating process. This makes it suitable for many heat-treated and dimensionally sensitive components that would be damaged by higher-temperature PVD or CVD methods.

Why Application Temperature Is a Critical Factor

The temperature required for a coating process is not a minor detail; it is often the primary constraint that determines whether a coating is viable for a specific application. High temperatures can fundamentally alter the part you are trying to improve.

Preserving Material Properties

Many high-performance components, such as tool steels, bearing races, and injection molds, undergo precise heat treatment processes to achieve a specific hardness and toughness.

If a coating process requires a temperature that exceeds the material's final tempering temperature, it will soften the substrate, effectively undoing the heat treatment and compromising the part's structural integrity. The sub-300°C range for DLC is safely below the tempering point for most common tool steels.

Minimizing Dimensional Distortion

Precision is paramount in modern engineering. Components like hydraulic pistons, fuel injectors, and optical molds have tolerances measured in microns.

Exposing these parts to excessive heat can cause them to warp, expand, or distort, rendering them useless. The low temperature of DLC deposition significantly minimizes the risk of thermal distortion, preserving the critical dimensions of the finished part.

The Deposition Process: More Than Just Heat

The temperature is not an isolated variable; it is one part of a complex system that includes the deposition method and substrate preparation.

PACVD Enables Low Temperatures

DLC is often applied using Plasma-Assisted Chemical Vapor Deposition (PACVD). In this process, a high-energy plasma is used to break down precursor gases and deposit the carbon film.

The energy from the plasma, rather than extreme thermal energy, drives the reaction. This is what allows the deposition to occur at a much lower temperature compared to traditional CVD or some PVD processes that can exceed 500°C.

The Critical Role of Bonding Layers

Achieving strong adhesion at low temperatures is a significant challenge. The reference correctly highlights the solution: the use of adhesion-promoting interlayers.

Before the DLC is applied, a very thin bonding layer, often silicon-based, is deposited onto the substrate. This layer acts as a bridge, creating a strong chemical and mechanical bond between the base material (like steel) and the subsequent DLC film. Without this layer, the coating would likely fail under stress.

Understanding the Trade-offs

While the low temperature of DLC is a major benefit, it comes with considerations that must be managed for a successful outcome.

Substrate Compatibility and Preparation

The process is "low temperature" relative to other hard coatings, but 300°C is still too hot for many plastics and some low-melting-point alloys.

Furthermore, ferrous metals like steel are ideal substrates. Other materials, such as aluminum, titanium, or copper alloys, require specialized and often proprietary interlayer systems to manage differences in thermal expansion and ensure proper adhesion.

Process Control is Everything

The final properties of a DLC coating—its hardness, friction, and adhesion—are controlled by a careful balance of gas chemistry, plasma density, and temperature.

A reputable coating provider doesn't just set the chamber to 300°C. They optimize the entire process for a specific substrate and application, ensuring the temperature delivers the best balance of properties without compromising the part.

Making the Right Choice for Your Goal

The suitability of DLC's application temperature is directly tied to the material of your component and your performance objectives.

- If your primary focus is coating hardened steels: DLC is an excellent choice, as the process temperature is typically well below the tempering point, preserving the substrate's hardness.

- If your primary focus is maintaining tight tolerances: The low deposition temperature of DLC makes it a superior option to high-heat processes, minimizing the risk of part distortion.

- If your primary focus is coating non-ferrous or sensitive materials: You must consult a coating specialist to discuss custom interlayer solutions required for proper adhesion and substrate safety.

Ultimately, understanding the relationship between temperature, process, and substrate is the key to successfully leveraging the unique benefits of DLC.

Summary Table:

| Key Aspect | Detail |

|---|---|

| Typical Application Temperature | ~300°C (572°F) |

| Primary Advantage | Low temperature prevents substrate damage |

| Key Process | Plasma-Assisted Chemical Vapor Deposition (PACVD) |

| Critical Requirement | Adhesion-promoting interlayers (e.g., silicon-based) |

| Ideal Substrates | Hardened tool steels, precision components |

| Main Benefit | Preserves material properties and dimensional tolerances |

Ready to enhance your precision components with a low-temperature DLC coating?

KINTEK specializes in advanced lab equipment and consumables for surface engineering, including PACVD systems optimized for DLC applications. Our expertise ensures your heat-treated steels and dimensionally sensitive parts receive a durable, high-performance coating without compromising their structural integrity.

We help you:

- Preserve substrate hardness and tolerances

- Achieve excellent coating adhesion with specialized interlayers

- Optimize the coating process for your specific material and application

Contact us today to discuss how our DLC solutions can solve your wear and friction challenges. Get in touch with our experts for a tailored consultation.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What is the difference between PECVD and sputter? Choose the Right Thin-Film Deposition Method

- What is plasma enhanced chemical vapor deposition PECVD equipment? A Guide to Low-Temperature Thin Film Deposition