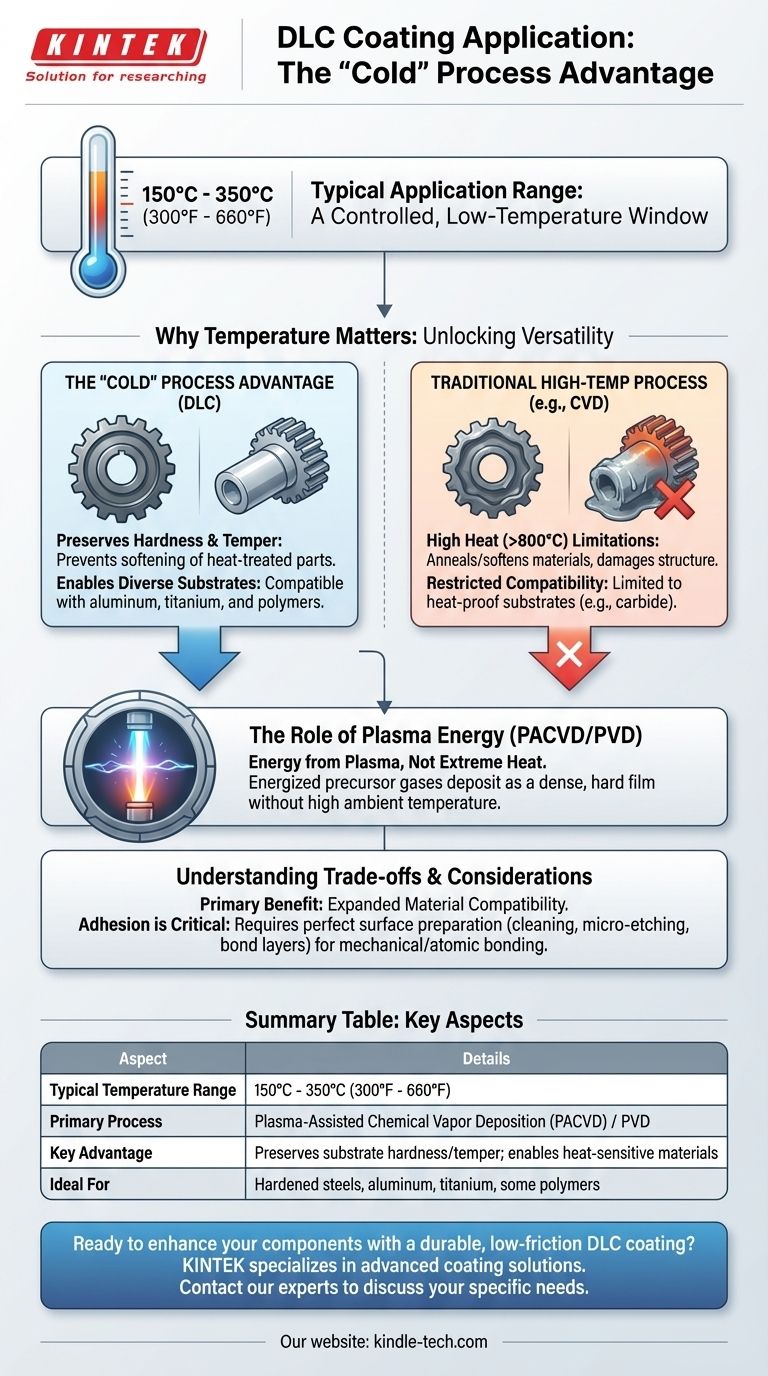

The application temperature for DLC coatings is not a single value, but a controlled range. This process typically takes place at relatively low temperatures, generally between 150°C and 350°C (approximately 300°F to 660°F). This low-temperature window is a defining characteristic and a primary advantage of the technology, enabling its use on materials that cannot withstand the extreme heat of other coating methods.

The crucial insight is that Diamond-Like Carbon (DLC) coating is fundamentally a "cold" process compared to traditional hard coatings. This low deposition temperature is what allows it to be applied to a vast range of materials, including heat-treated steels, aluminum, and even some polymers, without damaging their underlying structure or properties.

Why Temperature Is the Key to DLC's Versatility

The temperature of any coating process directly impacts the materials it can be applied to. The relatively low heat of DLC application is not a limitation but its most significant feature, driven by the physics of the process itself.

Preserving Material Hardness and Temper

Many high-performance components, such as tool steels, gears, and injection molds, undergo precise heat-treatment processes to achieve a specific hardness and toughness (temper).

Applying a traditional high-temperature coating, which can exceed 800°C (1475°F), would anneal or soften these parts, destroying their engineered properties and rendering them useless. The low temperature of the DLC process ensures the substrate's temper and structural integrity remain unaffected.

Enabling a Wider Range of Substrates

The low heat requirement opens the door to coating materials that are fundamentally incompatible with high-temperature processes.

This includes non-ferrous metals like aluminum and titanium, which have lower melting or deformation points. It also makes it possible to coat certain high-performance polymers and other temperature-sensitive composites.

The Role of Plasma Energy

DLC coatings are typically applied using a process called Plasma-Assisted Chemical Vapor Deposition (PACVD) or a form of Physical Vapor Deposition (PVD).

Instead of relying solely on thermal energy (extreme heat) to create the coating, these methods use a high-energy plasma field. The plasma energizes precursor gas molecules (like the hydrocarbons mentioned in the process), allowing them to break apart and deposit onto the component's surface as a dense, hard film without requiring high ambient temperatures.

Understanding the Trade-offs and Considerations

While the low temperature is a powerful advantage, it's essential to understand its context and implications compared to other methods.

The "Cold" Process Advantage

The primary benefit is clear: material compatibility. You can add the superior hardness, low friction, and wear resistance of DLC to components that would be destroyed by other coating processes. This drastically expands design and engineering possibilities.

Comparison with High-Temperature Processes

In contrast, conventional Chemical Vapor Deposition (CVD) coatings often require temperatures of 900°C to 1100°C. While these can produce extremely thick and durable coatings, their use is restricted to materials that can survive the heat, such as tungsten carbide.

Adhesion Requires Perfect Preparation

Because the DLC process does not create a deep, thermally-diffused bond with the substrate, achieving perfect adhesion is critical. The bonding is primarily mechanical and atomic.

This means that surface preparation—including ultrasonic cleaning, micro-etching, and the application of specific bond layers—is absolutely paramount to the coating's success. Any failure in preparation will lead to poor adhesion.

Making the Right Choice for Your Material

Your choice must be driven by the material you are working with and your performance goals. The process temperature is often the deciding factor.

- If your primary focus is coating hardened steels or precision components: The standard sub-350°C DLC process is ideal because it will not alter the material's carefully set temper or critical dimensions.

- If your primary focus is coating aluminum, titanium, or other non-ferrous alloys: DLC is one of the few high-performance hard coatings suitable for these materials precisely because of its low application temperature.

- If your primary focus is maximum durability on a heat-proof substrate (e.g., carbide): You might also evaluate high-temperature CVD coatings, but DLC often provides a superior combination of low friction, hardness, and cost-effectiveness.

Ultimately, understanding the low-temperature nature of the DLC process empowers you to enhance and protect a wider range of materials without compromise.

Summary Table:

| Key Aspect | Details |

|---|---|

| Typical Temperature Range | 150°C - 350°C (300°F - 660°F) |

| Primary Process | Plasma-Assisted Chemical Vapor Deposition (PACVD) / PVD |

| Key Advantage | Preserves substrate hardness and temper; enables coating of heat-sensitive materials |

| Ideal For | Hardened steels, aluminum, titanium, and some polymers |

Ready to enhance your components with a durable, low-friction DLC coating?

KINTEK specializes in advanced coating solutions for laboratory and industrial applications. Our expertise ensures your hardened steels, aluminum alloys, and other temperature-sensitive materials receive a high-performance DLC coating without compromising their structural integrity.

Contact our experts today to discuss how our lab equipment and consumables can provide the perfect coating solution for your specific needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory CVD Boron Doped Diamond Materials

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What is plasma activated chemical vapor deposition? Enable Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is plasma enhanced? A Guide to Low-Temperature, High-Precision Manufacturing

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition