For metal casting, the most common equipment is a crucible furnace. This type of furnace is specifically designed to contain and heat a separate, removable pot (the crucible) filled with metal until it becomes molten. Once the metal is liquid, the crucible is lifted from the furnace and used to pour the metal into a mold. While other specialized furnaces exist for industrial-scale operations, the crucible furnace is the foundational tool for most casting work.

The term "furnace" is broad, but for metal casting, the choice is not about finding one "best" type. It's about matching the heating technology—fuel, electric resistance, or induction—to the specific metal you need to melt, the volume you're casting, and the precision you require.

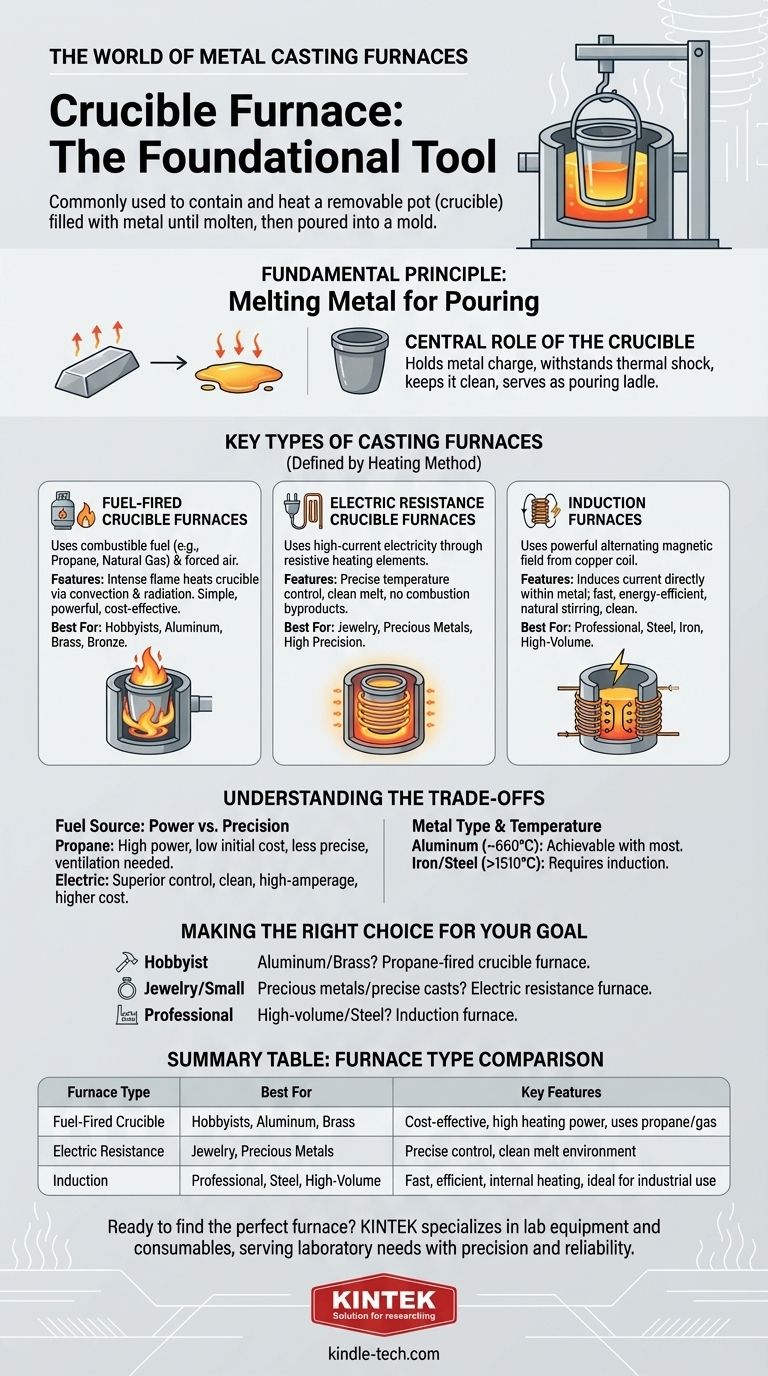

The Fundamental Principle: Melting Metal for Pouring

The primary goal of a casting furnace is simple: to transfer enough thermal energy into a solid metal to raise its temperature beyond its melting point. The method of heat transfer is what differentiates the various furnace types.

The Central Role of the Crucible

A crucible is a ceramic or graphite container engineered to withstand extreme thermal shock. It acts as the vessel that holds the metal charge, keeps it clean during melting, and serves as the pouring ladle. The furnace is essentially a well-insulated box built around the crucible.

The Heating Method Defines the Furnace

The furnace's design is dictated by how it generates and applies heat to the crucible. This is the most important factor in distinguishing between types.

Key Types of Casting Furnaces

While many furnace designs exist, they generally fall into three categories relevant to small-shop and industrial casting.

Fuel-Fired Crucible Furnaces

These are the most common furnaces for hobbyists and small foundries. They use a combustible fuel, typically propane or natural gas, mixed with forced air to create an intense flame.

The flame swirls around the exterior of the crucible inside the insulated furnace body, heating it through convection and radiation. They are relatively simple, powerful, and cost-effective, making them ideal for melting non-ferrous metals like aluminum, brass, and bronze.

Electric Resistance Crucible Furnaces

These furnaces use high-current electricity passed through resistive heating elements that line the furnace's interior walls. These elements glow red-hot, radiating intense heat onto the crucible.

Electric furnaces offer far more precise temperature control than fuel-fired versions and produce no combustion byproducts, resulting in a cleaner melt. They are favored by jewelers and for applications involving precious metals or alloys that require tight process control.

Induction Furnaces

Induction furnaces represent the modern standard for professional foundries. They do not use conventional heating elements or flames. Instead, they use a powerful alternating magnetic field generated by a copper coil.

This magnetic field "induces" an electric current directly within the metal itself, causing it to heat rapidly from the inside out. This method is extremely fast, energy-efficient, and clean, and it naturally stirs the molten metal, ensuring an even temperature and composition. It is the preferred method for melting steel, iron, and large volumes of any metal.

Understanding the Trade-offs

Choosing a furnace involves balancing cost, performance, and operational complexity. What is ideal for one user may be entirely wrong for another.

Fuel Source: Power vs. Precision

A propane-fired furnace offers immense heating power for a low initial cost but can be difficult to control precisely. It also requires proper ventilation for exhaust fumes and careful management of fuel tanks.

An electric resistance furnace provides superior control and a clean environment but requires a dedicated, high-amperage electrical circuit and typically has a higher purchase price for its size.

Metal Type and Temperature Requirements

Your choice of metal dictates the required temperature. Aluminum melts around 1220°F (660°C), which is easily achievable with most hobbyist furnaces.

Melting cast iron or steel, however, requires temperatures exceeding 2750°F (1510°C). This level of heat is generally beyond the practical capability of typical propane or resistance furnaces and is best handled by an induction furnace.

Scale and Safety

A hobbyist melting a few pounds of aluminum has very different needs than a foundry pouring hundreds of pounds. Fuel-fired furnaces scale well for small-to-medium jobs.

For any significant volume or professional operation, the speed, efficiency, and safety features of an induction furnace make it the superior long-term investment.

Making the Right Choice for Your Goal

Your furnace choice should be guided directly by your casting ambitions and the materials you intend to use.

- If your primary focus is hobbyist casting with aluminum or brass: A propane-fired crucible furnace offers the best combination of low cost and high heating power to get started.

- If your primary focus is jewelry or small, precise casts with precious metals: An electric resistance furnace provides the essential temperature control and clean melting environment you need.

- If your primary focus is professional, high-volume, or steel casting: An induction furnace is the industry standard for its unmatched speed, efficiency, and control.

By understanding that the furnace is a tool matched to a specific task, you can confidently select the right equipment to melt metal safely and effectively.

Summary Table:

| Furnace Type | Best For | Key Features |

|---|---|---|

| Fuel-Fired Crucible | Hobbyists, Aluminum, Brass | Cost-effective, high heating power, uses propane/gas |

| Electric Resistance | Jewelry, Precious Metals | Precise temperature control, clean melt environment |

| Induction | Professional, Steel, High-Volume | Fast, efficient, internal heating, ideal for industrial use |

Ready to find the perfect furnace for your casting needs? KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision and reliability. Whether you're a hobbyist working with aluminum or a professional melting steel, our experts can help you select the right furnace for your specific metal, volume, and precision requirements. Contact us today to enhance your casting efficiency and achieve superior results!

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What factors influence the general design of a tube furnace? Match Your Process with the Perfect System

- What precautions should be taken when using a tube furnace? Ensure Safe, Effective High-Temperature Processing

- How does a high-temperature tube furnace facilitate the phase transformation of alumina products? Master Thermal Control

- Why is a quartz tube furnace utilized in the thermal oxidation of MnCr2O4 coatings? Unlock Precise Selective Oxidation

- What materials are used for the tubes in tube furnaces? A Guide to Selecting the Right Tube for Your Process