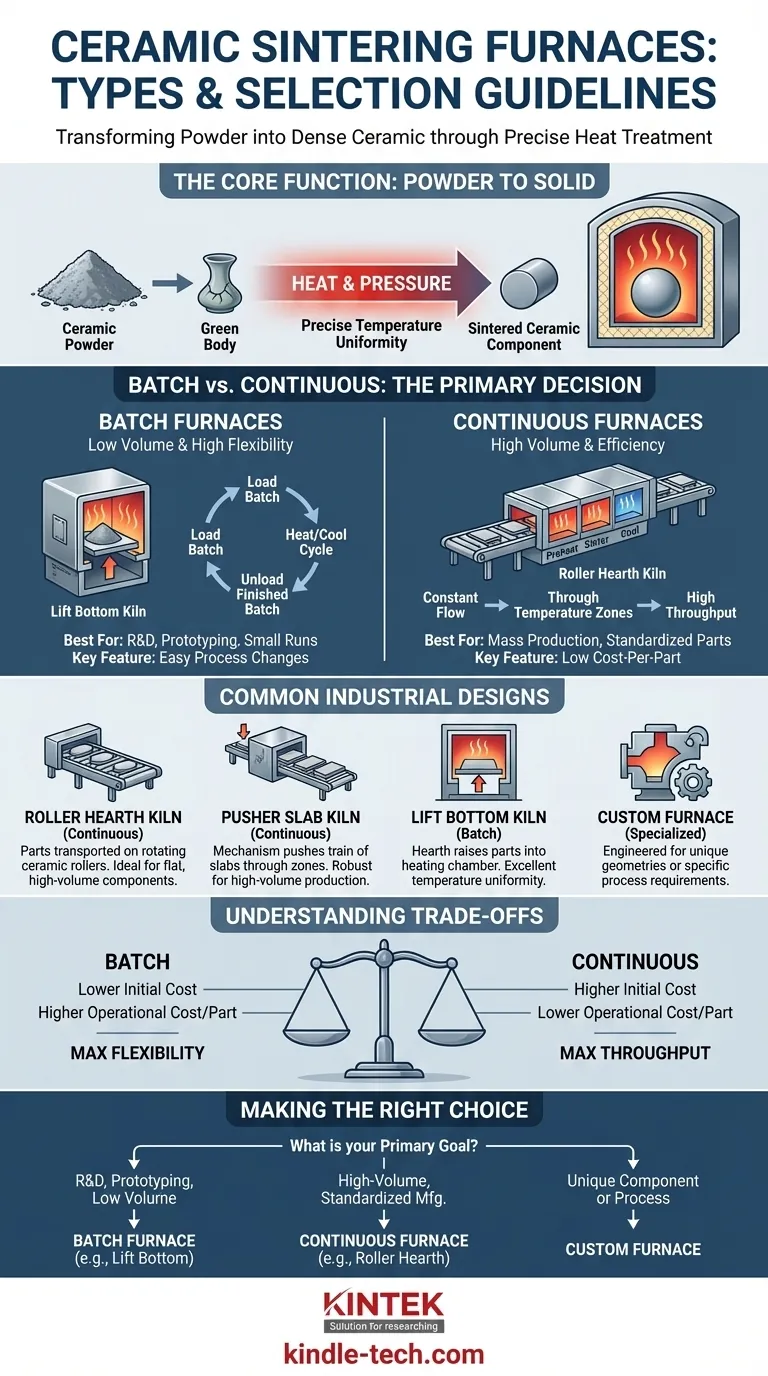

In short, furnaces for sintering ceramics are broadly classified into two main operational types: batch furnaces for lower volumes and continuous furnaces for high-volume production. Specific designs commonly used in industrial settings include Roller Hearth Kilns, Pusher Slab Kilns, and Lift Bottom Kilns, with custom-built furnaces available for highly specialized applications.

The choice of a sintering furnace is not about finding a single "best" type. It is about aligning the furnace's operational model—batch, continuous, or custom—with your specific production volume, material requirements, and desired final product properties.

The Core Function: Transforming Powder into a Solid

Before comparing furnace types, it's critical to understand the process they are designed to facilitate. Sintering is a high-temperature heat treatment that solidifies ceramic components.

From Green Body to Dense Ceramic

The process begins with a "green body"—a fragile part formed from ceramic powders. The sintering furnace applies precise heat, causing the individual particles to bond and fuse together. This densifies the material, transforming it from a delicate shape into a hard, strong ceramic component with excellent final properties.

The Critical Role of Temperature Uniformity

The success of sintering hinges on precise temperature control and uniformity. The furnace must maintain a consistent temperature across the entire part and throughout the production run. Modern furnaces achieve this using features like advanced control systems and highly efficient ceramic fiber insulation.

Batch vs. Continuous: The Primary Decision

The most fundamental distinction between sintering furnaces is their mode of operation. This choice directly impacts production capacity, flexibility, and cost.

Batch Furnaces: For Flexibility and Development

Batch furnaces, such as Lift Bottom Kilns, process one set or "batch" of parts at a time. The parts are loaded, the furnace runs its heating and cooling cycle, and the finished batch is unloaded.

These furnaces are ideal for low-volume production, research and development (R&D), and prototyping. Their key advantage is flexibility; you can easily change the cycle parameters for different products.

Continuous Furnaces: For Efficiency and Mass Production

Continuous furnaces, like Roller Hearth Kilns or Pusher Slab Kilns, are designed for a constant flow of material. Parts move continuously through different temperature zones within the furnace, enabling high-volume output.

These systems are the workhorses of medium- to high-volume manufacturing. They offer exceptional efficiency and consistency for standardized products, as the process runs in a steady state.

Common Furnace Designs Explained

While many variations exist, a few designs are prevalent in industrial ceramic sintering.

Roller Hearth Kilns

In this continuous design, parts are placed on trays or directly onto ceramic rollers that transport them through the furnace. This method is excellent for processing a high volume of flat or stable components.

Pusher Slab Kilns

Here, parts are loaded onto ceramic slabs or plates. A hydraulic or mechanical "pusher" mechanism intermittently pushes the train of slabs through the furnace's heating zones. This is another robust solution for high-volume continuous production.

Lift Bottom Kilns

A common type of batch furnace where the furnace body is stationary and the hearth (or "bottom") holding the parts is raised into it for the heating cycle. This design offers excellent temperature uniformity and is well-suited for large or complex parts.

Custom Furnaces

When a standard design cannot meet the requirements of a unique part geometry, atmospheric condition, or temperature profile, a custom furnace is engineered. These are built to the exact specifications of the application, ensuring optimal outcomes for niche product development or production.

Understanding the Trade-offs

Choosing a furnace involves balancing competing priorities. There is no one-size-fits-all solution.

Upfront Cost vs. Operational Cost

Batch furnaces typically have a lower initial investment but a higher operational cost per part due to less efficient energy use and manual loading/unloading.

Continuous furnaces demand a significant upfront investment but deliver a much lower cost-per-part at high volumes, making them more economical for mass production.

Flexibility vs. Throughput

The core trade-off is flexibility versus throughput. Batch furnaces offer maximum flexibility to alter processes for different products. Continuous furnaces prioritize maximum throughput for a single, optimized process.

Making the Right Choice for Your Goal

Your production goal should be the primary driver of your furnace selection.

- If your primary focus is research, prototyping, or low-volume specialty parts: A batch furnace offers the necessary process flexibility and a manageable initial investment.

- If your primary focus is high-volume, standardized manufacturing: A continuous furnace, such as a Roller Hearth or Pusher Slab Kiln, will provide the lowest cost-per-part and highest efficiency.

- If your primary focus is a unique component or highly specific process: A custom-designed furnace is the most direct path to ensuring your technical requirements are met without compromise.

Ultimately, selecting the right sintering furnace is a strategic decision that directly shapes the efficiency, cost, and quality of your final ceramic components.

Summary Table:

| Furnace Type | Operation | Best For | Key Features |

|---|---|---|---|

| Batch Furnaces | Single loads processed at a time | R&D, prototyping, low-volume | High flexibility, easy process changes |

| Continuous Furnaces | Constant flow of parts | Medium- to high-volume production | High throughput, low cost-per-part |

| Custom Furnaces | Tailored to specific needs | Unique geometries or processes | Engineered for exact application requirements |

Ready to optimize your ceramic sintering process? KINTEK specializes in lab equipment and consumables, offering tailored furnace solutions for laboratories and production facilities. Whether you need a flexible batch kiln for R&D or a high-efficiency continuous system for manufacturing, our expertise ensures precise temperature control, uniformity, and reliability for your ceramic components. Contact us today to discuss your specific needs and achieve superior sintering results!

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Mesh belt controlled atmosphere furnace

People Also Ask

- What are the types of pyrolysis reactors used in industry? Choose the Right Technology for Your Product

- What are the products of pyrolysis of wood? A Guide to Biochar, Bio-oil, and Syngas Yields

- What are the different types of reactors in plastic pyrolysis? Choose the Right System for Your Waste

- What is the difference between calcining and roasting? A Guide to High-Temperature Processing

- What is the purpose of a calciner? Boost Efficiency in High-Temperature Processing